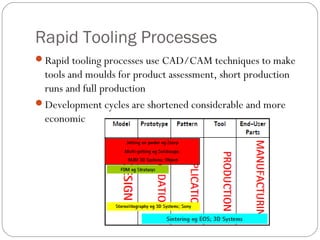

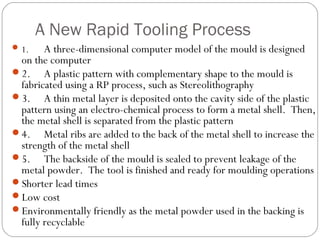

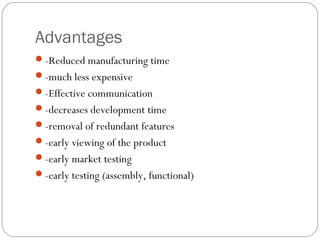

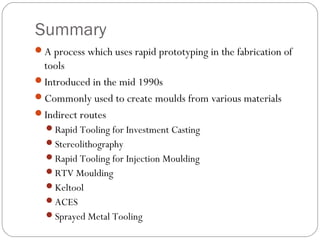

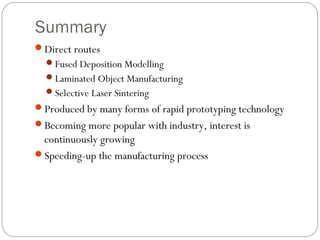

Rapid tooling uses 3D printing or other rapid prototyping techniques to quickly create molds, dies, or other tools for manufacturing parts in plastic or metal. There are direct methods that 3D print the tool and indirect methods that use a 3D printed pattern to create a traditional mold. Rapid tooling can reduce manufacturing time from months to weeks and is useful for prototyping or low-volume production. However, rapid tooling methods typically have shorter tool lifespans and lower accuracy than traditional metal tooling.