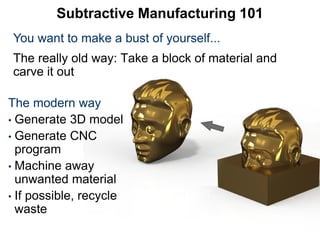

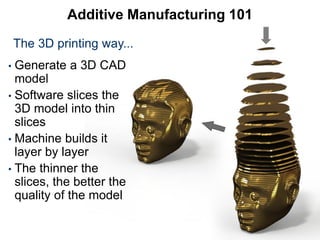

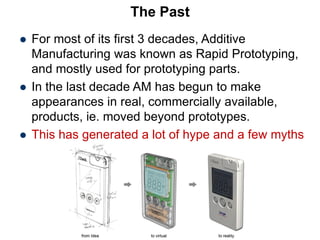

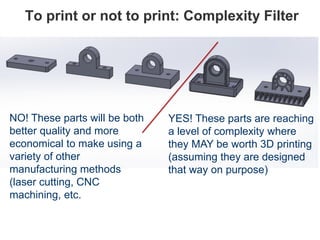

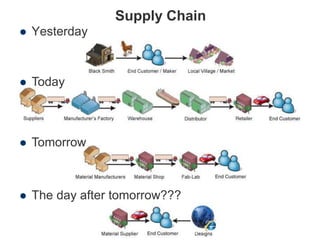

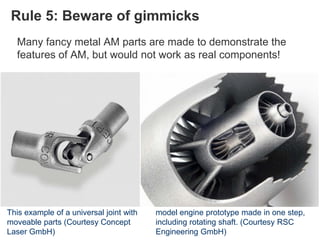

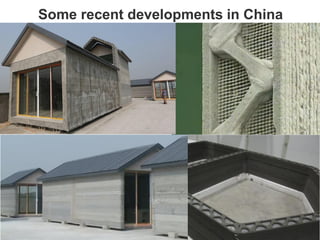

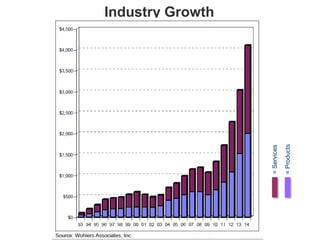

This document summarizes the advantages and current applications of additive manufacturing (AM), also known as 3D printing. It discusses how AM is useful for prototyping, mass customization, and encouraging innovation by lowering the costs associated with trying new ideas. While desktop 3D printers are useful for hobbyists, industrial 3D printers are needed to manufacture end-use products in metals and other materials. The document debunks some myths about AM and emphasizes the need to design parts specifically for the AM process to realize its full benefits.