1. Advancements in CAE and manufacturing technologies are providing opportunities for diversification and improvement in the metal casting industry. This includes award-winning optimized designs from topology optimization and simulations.

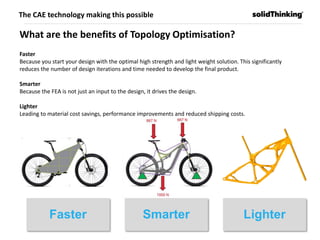

2. Companies are using these technologies to improve existing automotive and sports components, reducing weight by up to 50% while maintaining strength. This allows compliance with emissions regulations.

3. The technologies also enable feasible smaller production runs and diversification into new industries like tooling, with 3D printed fixtures. Overall these advancements are driving lighter, smarter, and more efficient product design.