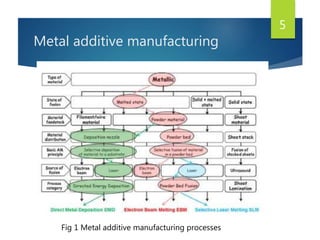

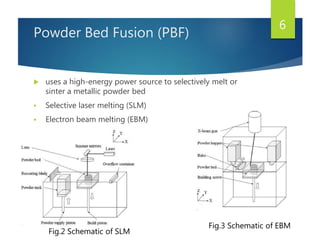

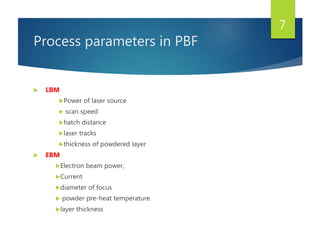

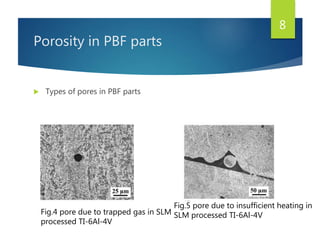

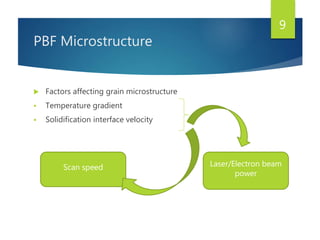

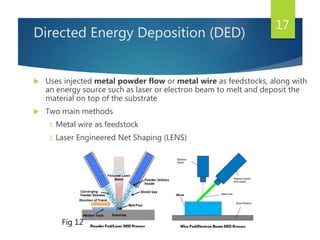

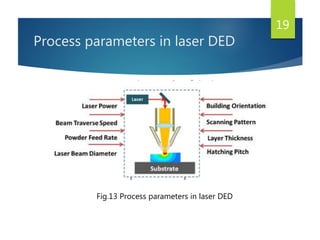

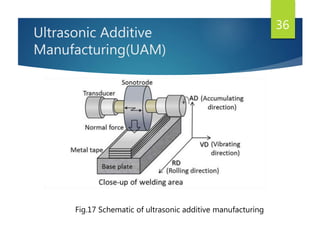

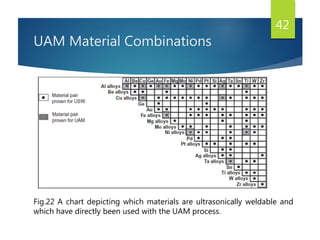

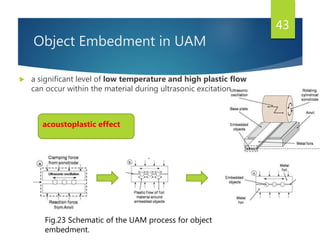

The document discusses various metal additive manufacturing techniques including powder bed fusion, directed energy deposition, binder jetting, and sheet lamination. Powder bed fusion techniques like selective laser melting use a laser to selectively fuse metal powder layers. Directed energy deposition techniques like laser engineered net shaping use a laser and metal powder or wire feedstock to deposit material. Binder jetting uses inkjet printing of a binder to join metal powder particles. Sheet lamination techniques like ultrasonic additive manufacturing bond metal foils using ultrasonic vibration. The document explores the process parameters, microstructures, and applications of these various metal 3D printing methods.