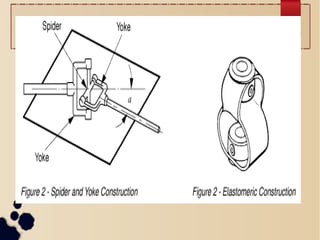

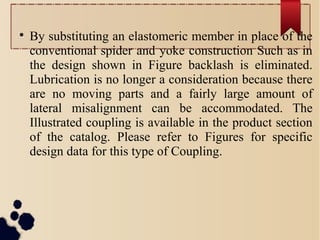

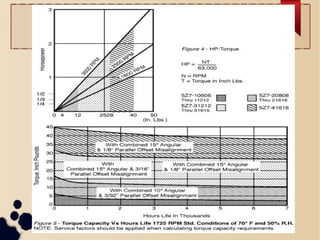

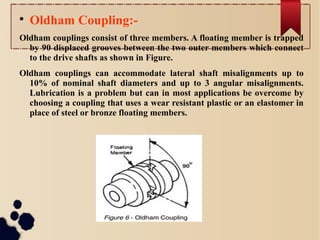

The document provides an overview of mechanical couplings, detailing their purpose, types, and applications. It elaborates on flexible couplings, such as universal and Oldham couplings, highlighting their advantages and limitations. Additionally, it covers flexible shafts and miscellaneous couplings, explaining their design considerations and operational efficiency.