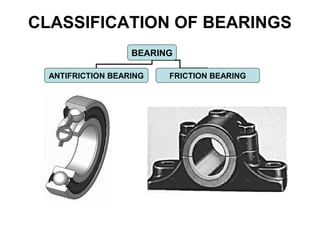

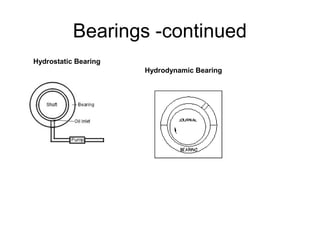

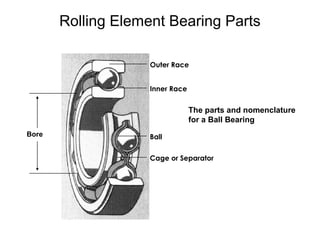

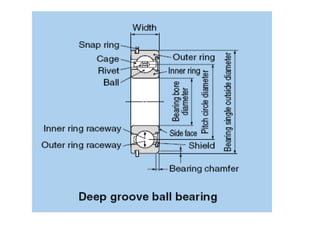

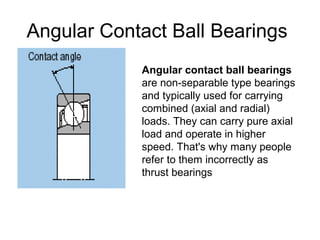

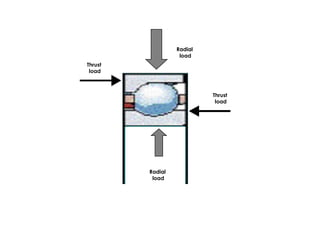

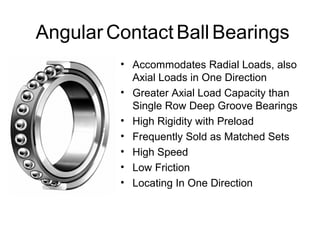

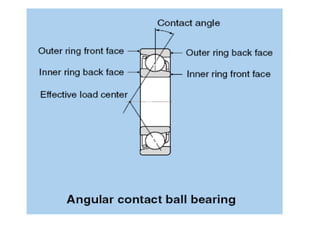

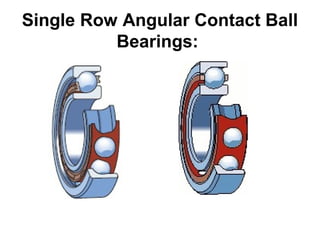

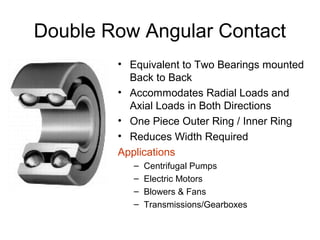

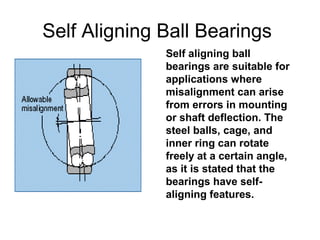

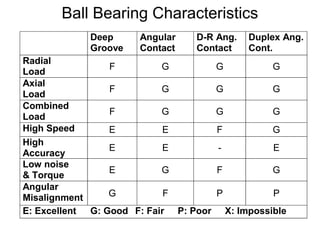

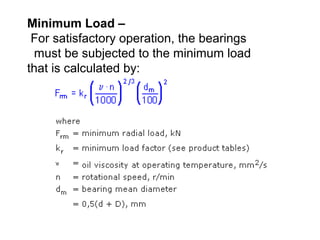

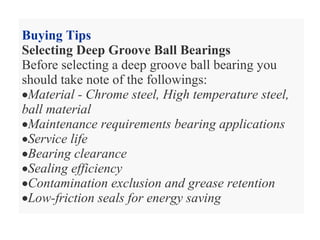

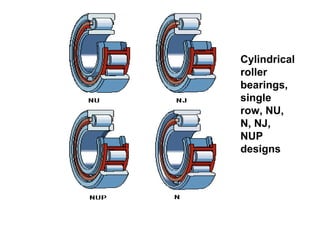

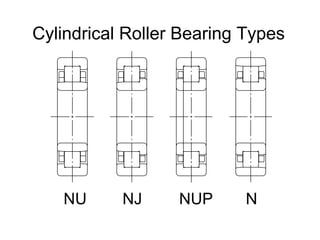

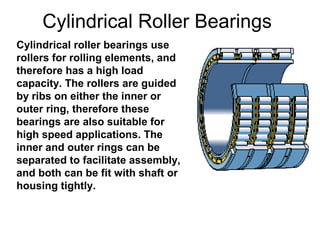

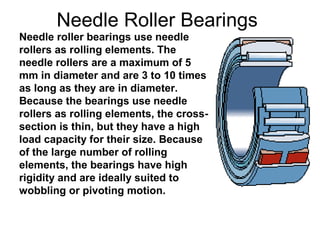

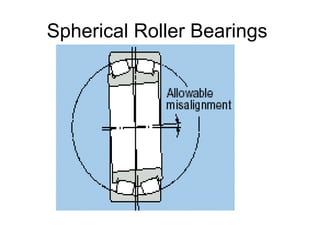

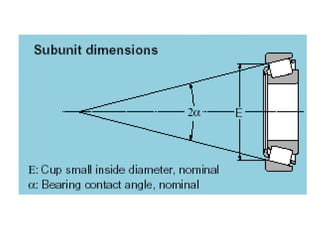

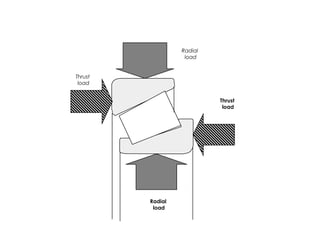

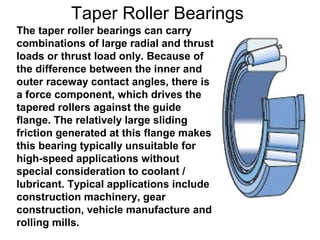

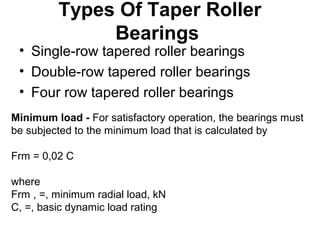

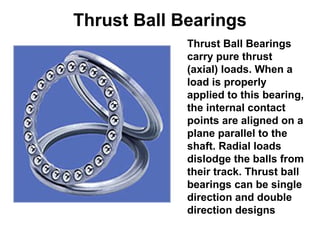

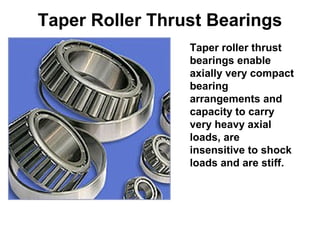

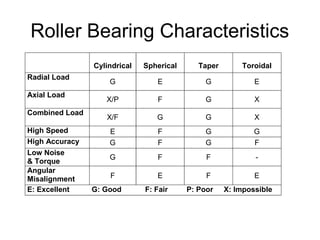

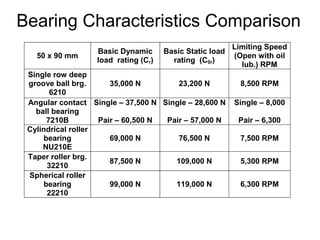

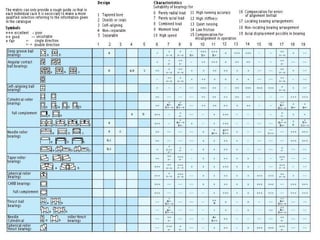

This document discusses different types of bearings. It begins by defining a bearing as a device that allows constrained relative motion between two parts, typically rotation or linear movement. It then classifies bearings based on the motions they allow and their principle of operation. The document goes on to describe various types of bearings in detail, including ball bearings, roller bearings, thrust bearings, tapered roller bearings, and cylindrical roller bearings. It provides information on the characteristics, advantages, applications, and physical features of each bearing type.