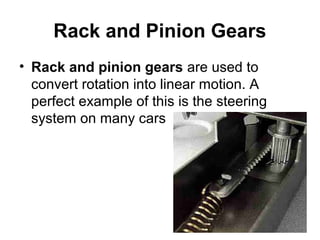

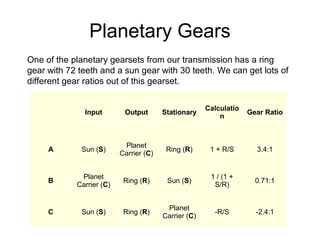

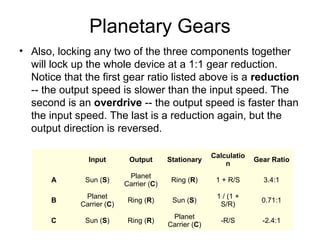

Gears are mechanical devices used to transmit rotational motion and torque between two shafts. The document discusses several types of gears including spur gears, helical gears, bevel gears, hypoid gears, worm gears, rack and pinion gears, and planetary gears. It explains how each type of gear works and common uses for different gear types.