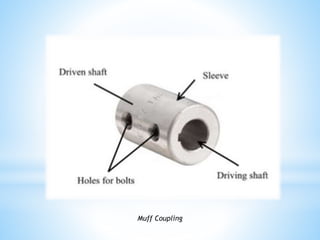

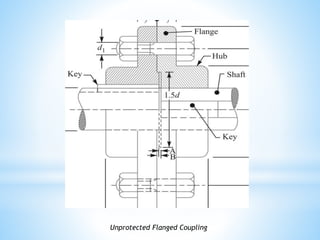

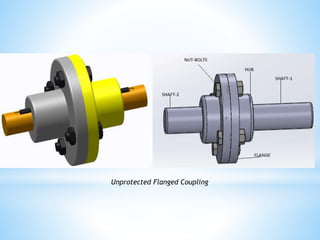

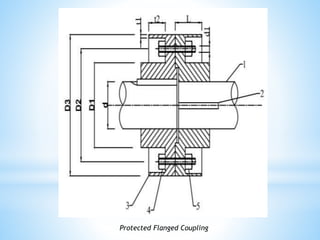

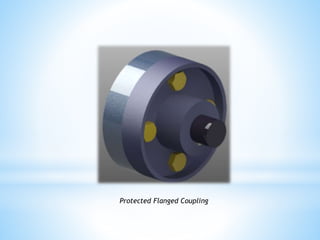

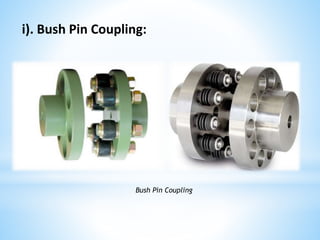

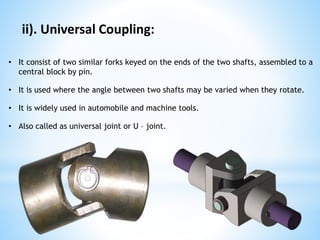

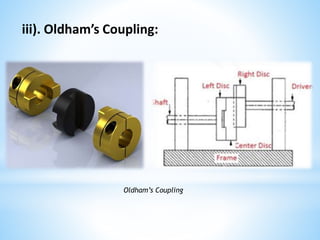

The document presents an overview of couplings, detailing their purpose, uses, types, and maintenance. Couplings are devices used to connect two shafts for power transmission, categorized into rigid and flexible types. The content also addresses the characteristics of a good coupling and common causes of coupling failures.