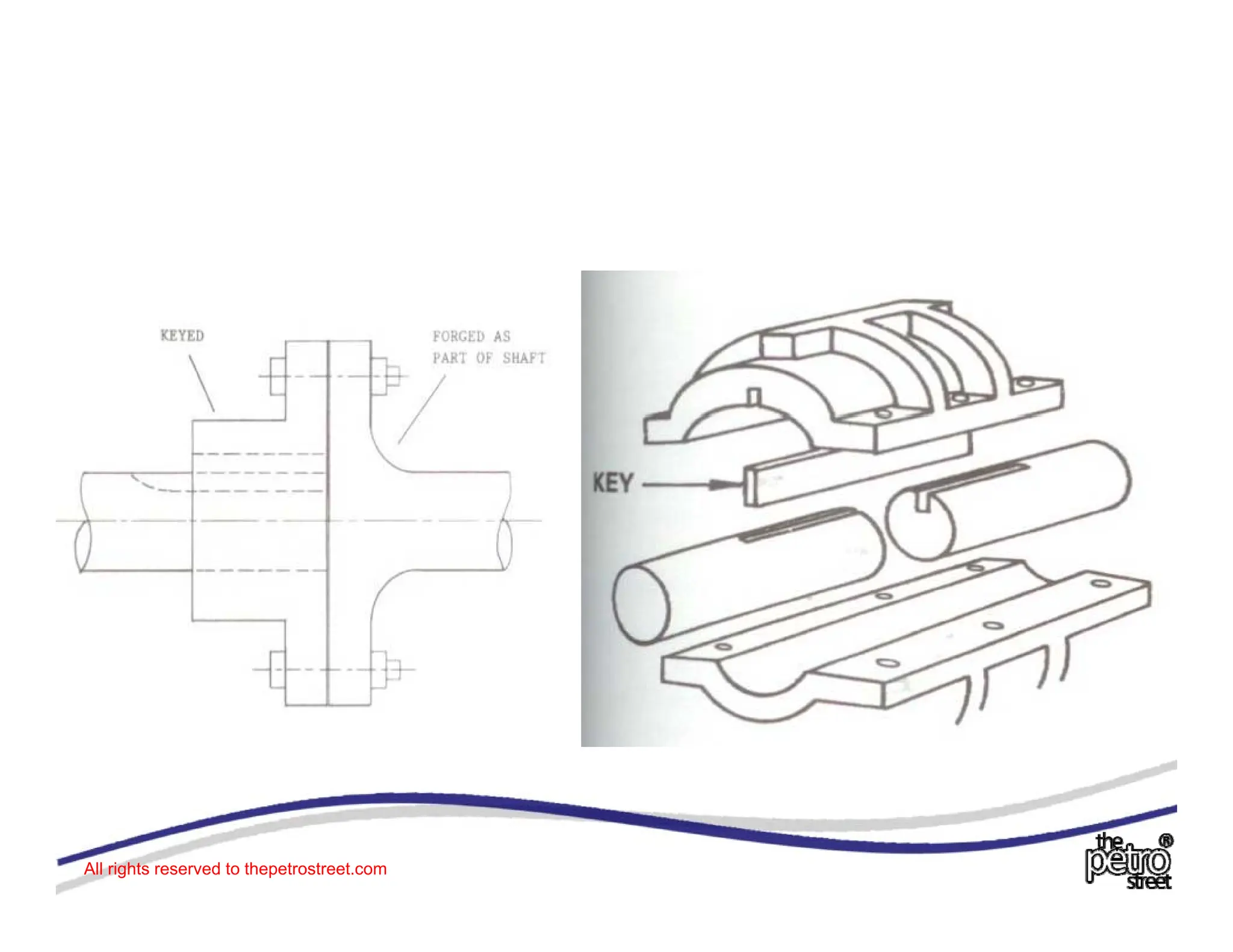

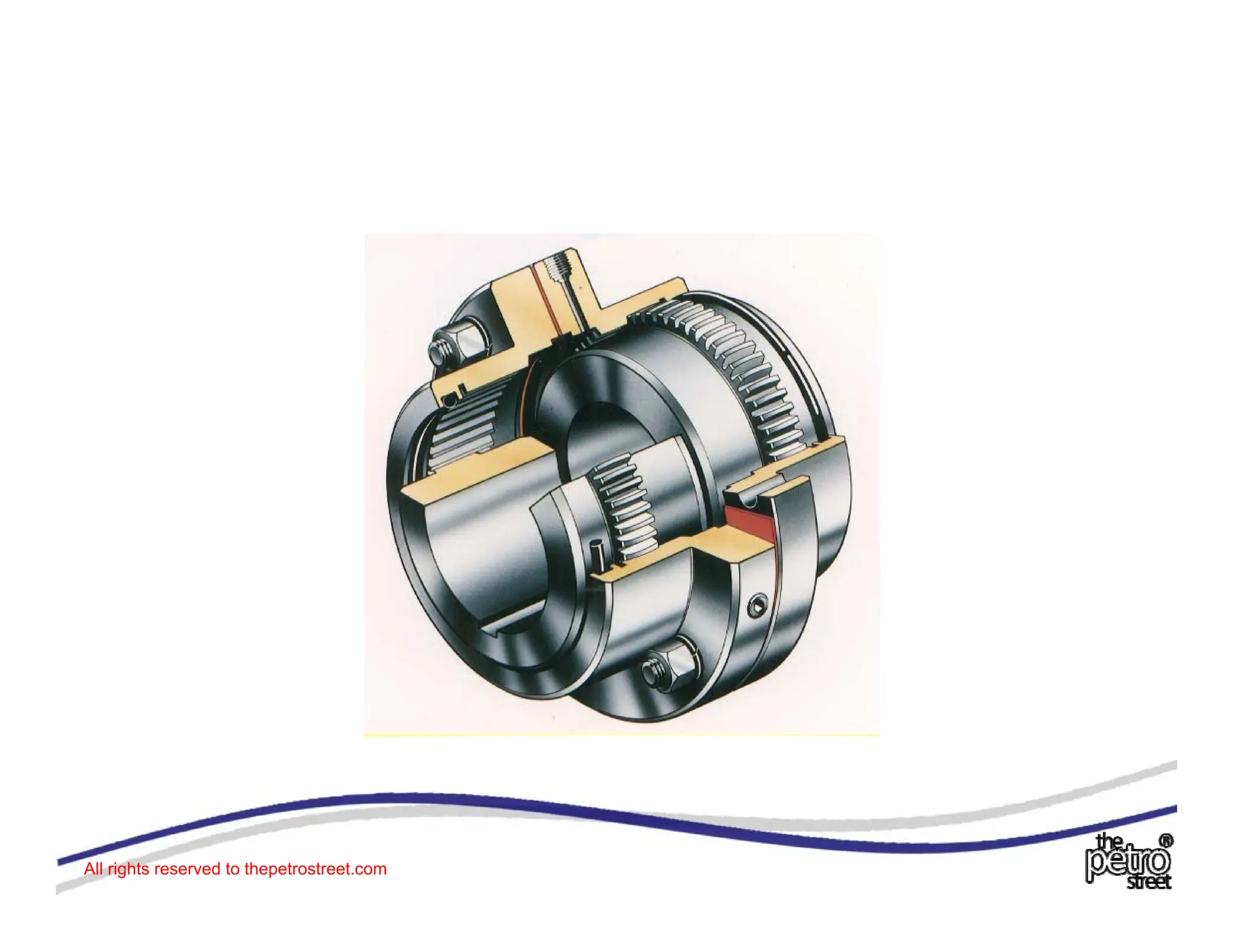

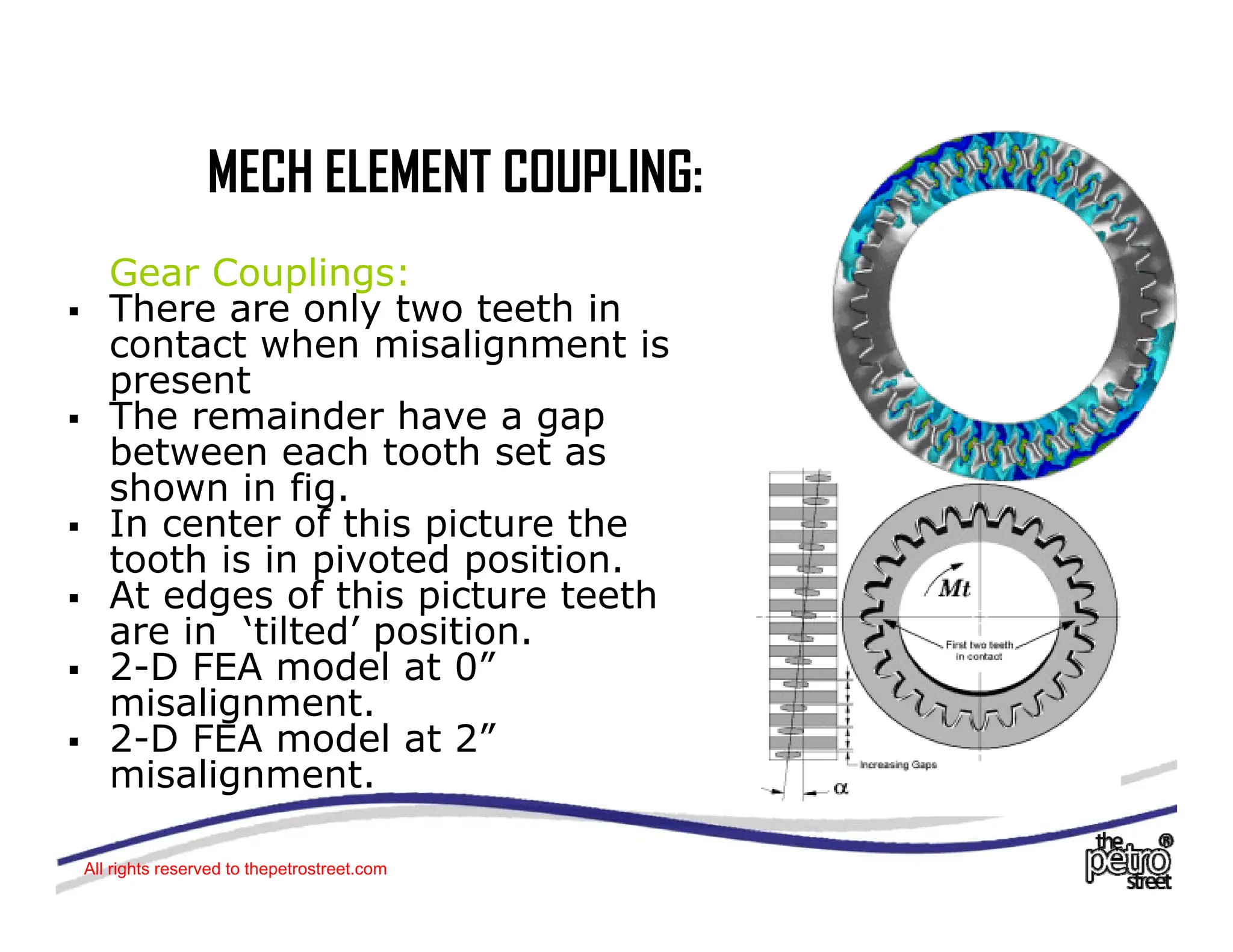

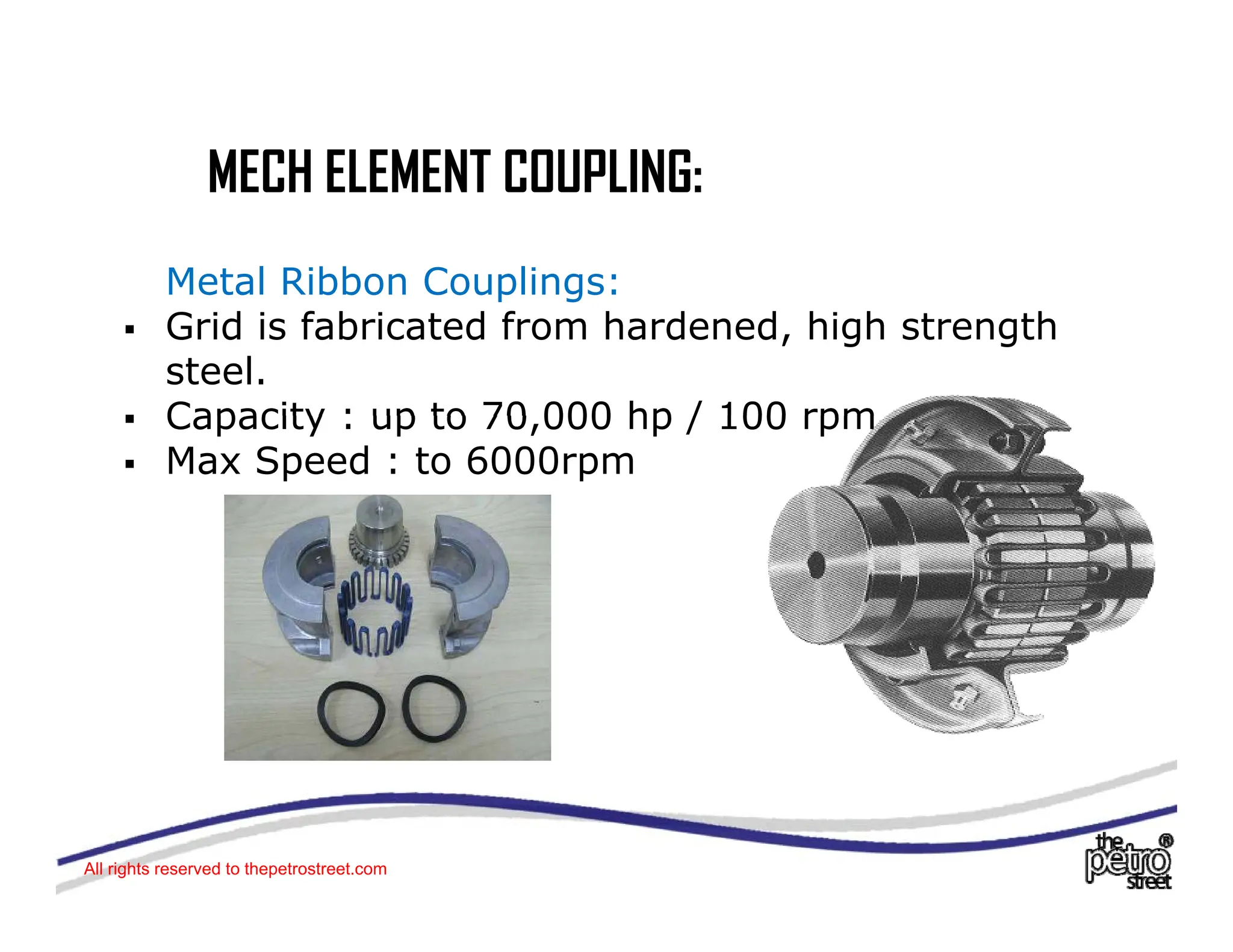

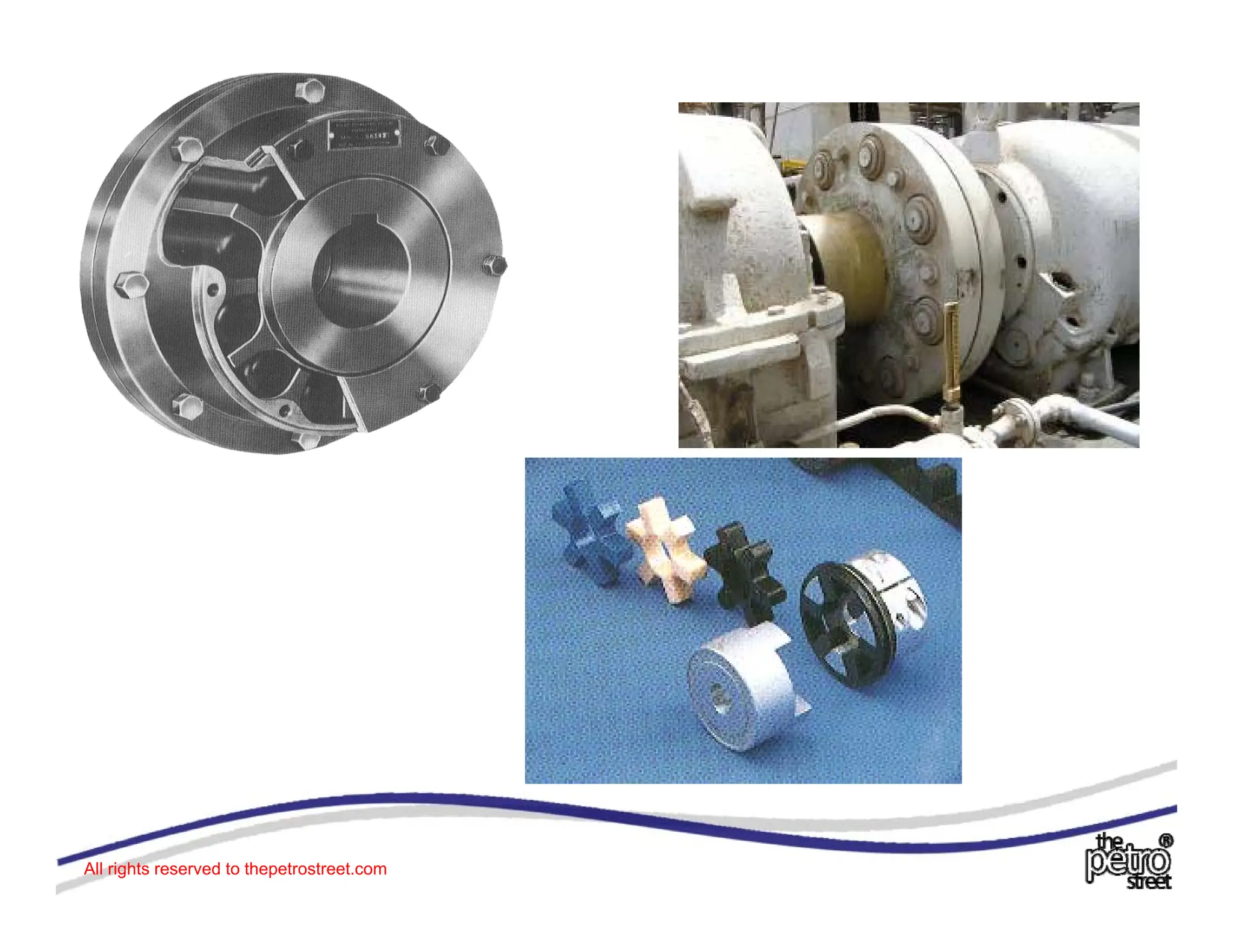

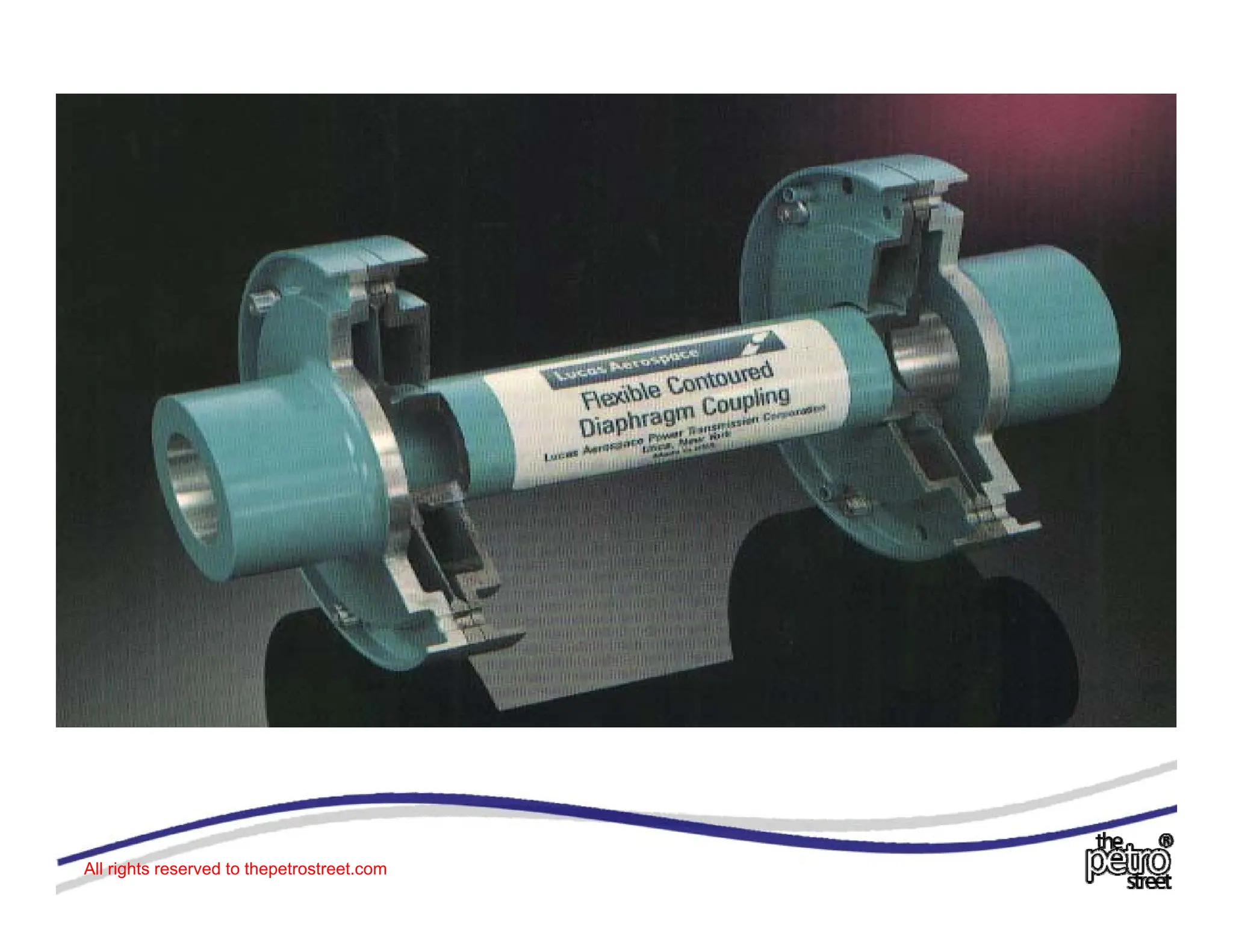

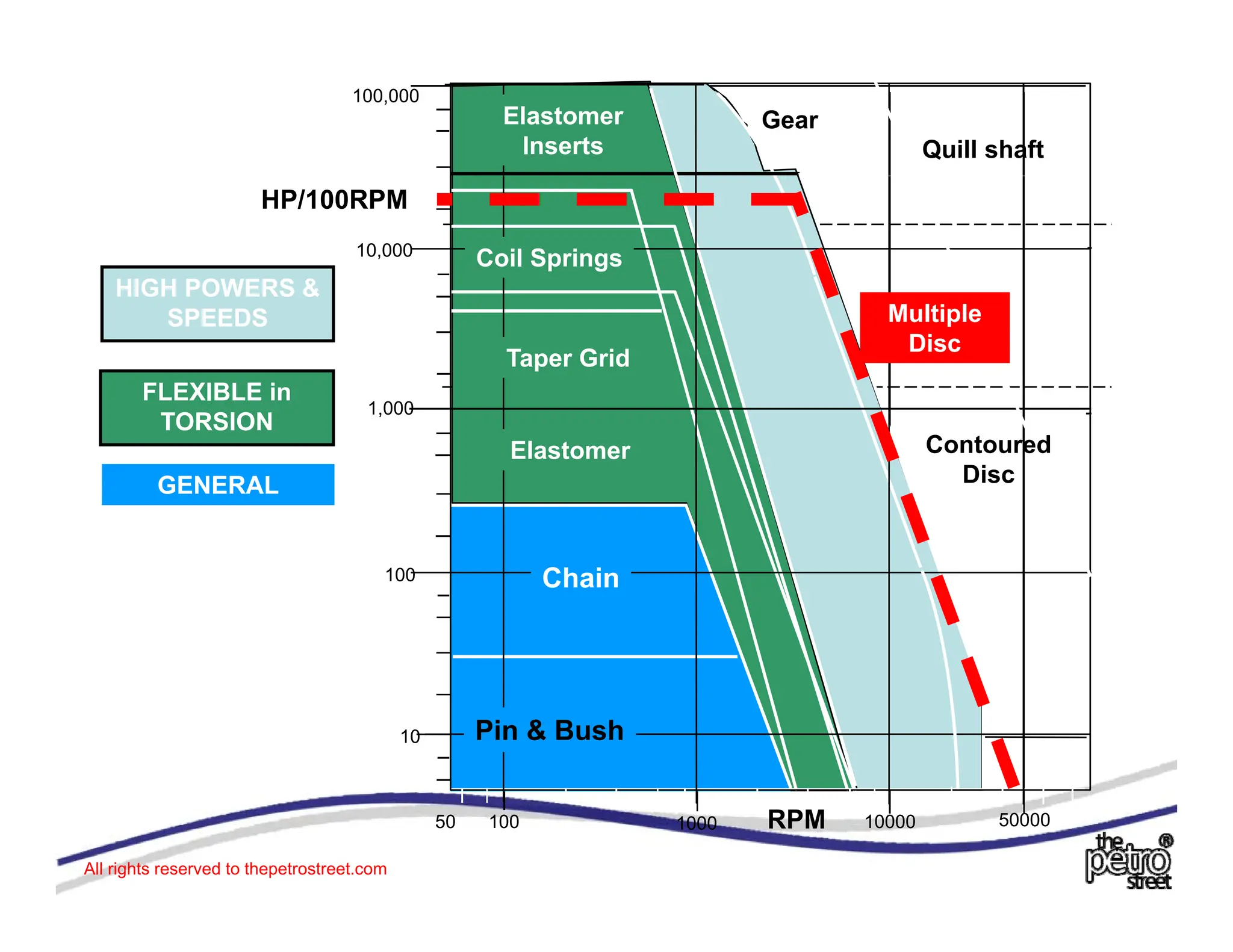

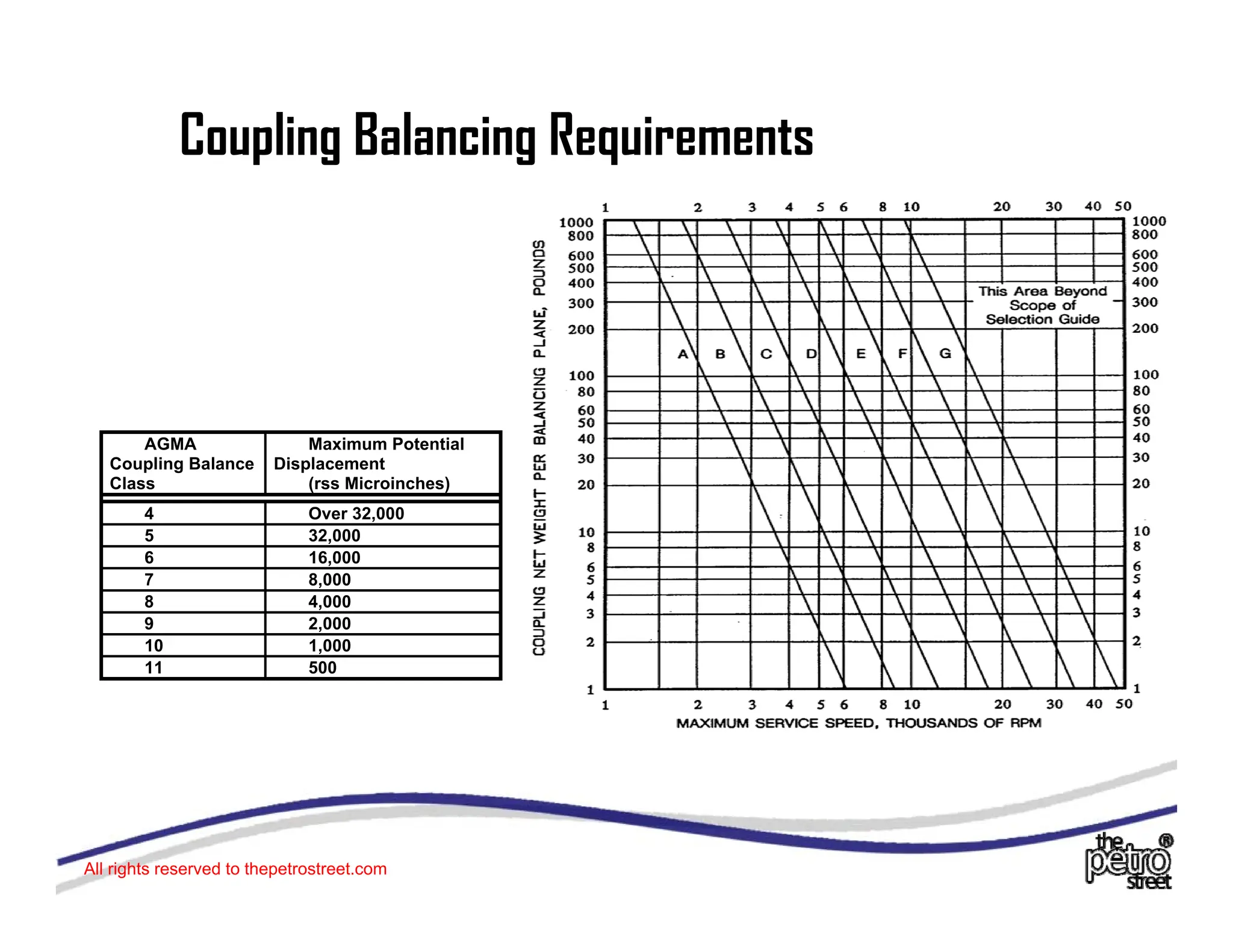

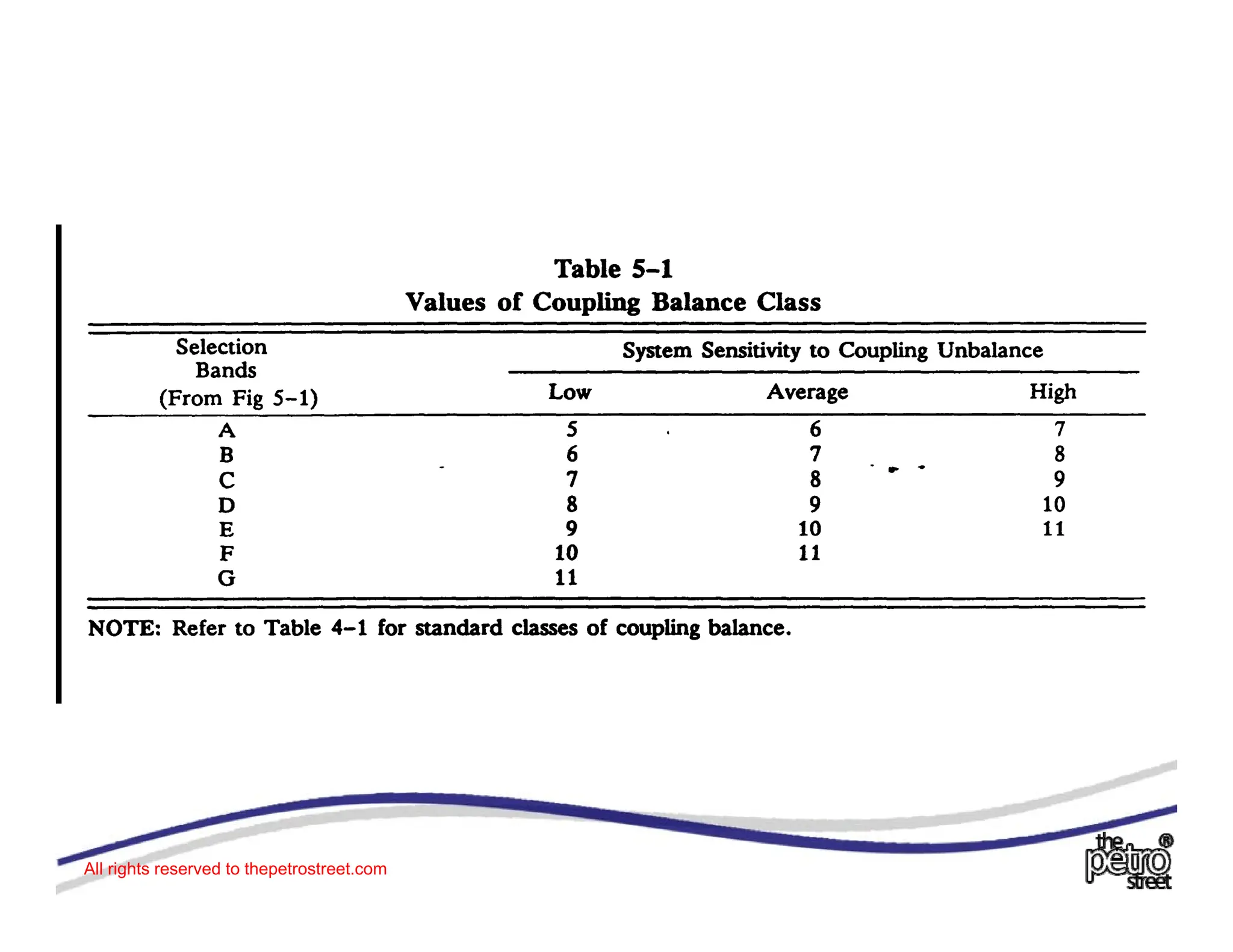

The document provides an overview of couplings, focusing on their types, purposes, and functions. It describes rigid and flexible couplings, their advantages and disadvantages, and details various types including mechanical, elastomeric, and metallic diaphragm couplings. Additionally, it includes coupling selection guidelines and balancing requirements to ensure optimal performance.