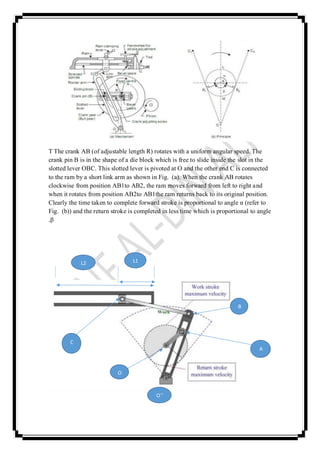

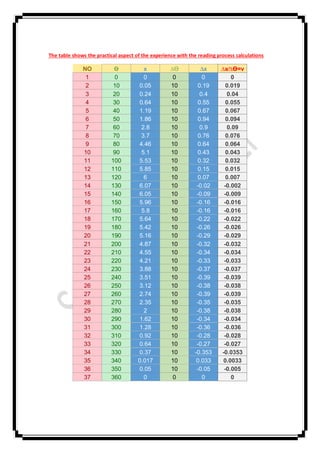

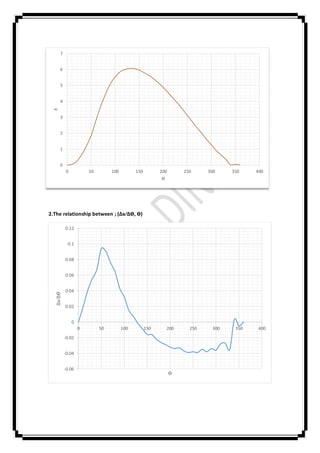

The document details the quick return mechanism, emphasizing its role in converting rotary motion to reciprocating motion in machines like shaping machines and impacting presses. It distinguishes between simple and compound mechanisms, explaining their applications and how they achieve varied stroke speeds to minimize non-productive time. Additionally, it covers theoretical calculations, kinematic analyses, and dynamic analyses relevant to the mechanism's function and performance.