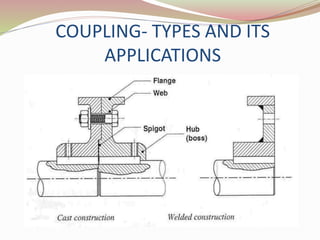

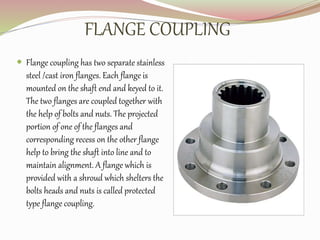

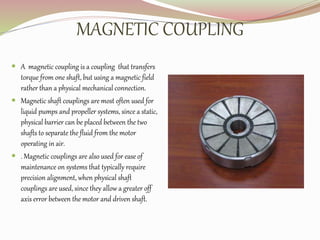

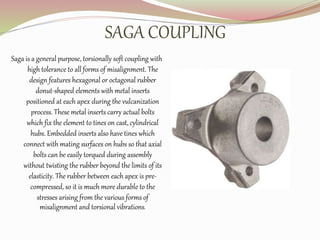

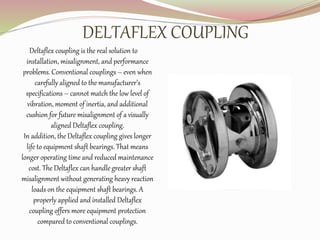

This document discusses various types of couplings, devices that connect two shafts to transmit power while accommodating misalignment. It describes specific coupling types, including rigid, sleeve, flange, geislinger, magnetic, saga, deltaflex, and torsional couplings, each with unique applications and benefits. The document emphasizes the importance of coupling selection and maintenance to reduce costs and improve equipment performance.