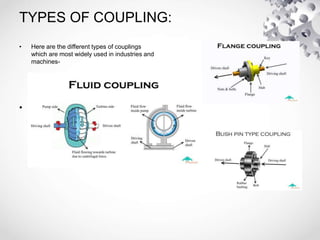

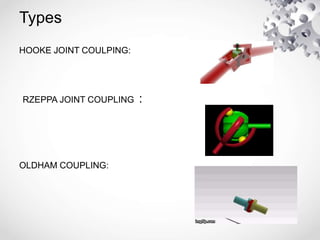

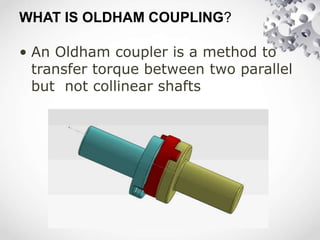

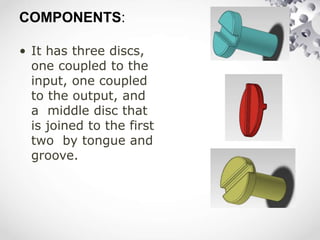

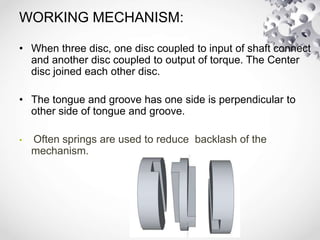

This document discusses Oldham couplings, which are used to transmit power between two parallel but non-collinear shafts. It describes how Oldham couplings work using three discs with interlocking tongues and grooves to allow for some misalignment of the shafts while preventing relative rotation. Advantages include low inertia, stiffness, ease of installation in tight spaces. Disadvantages include smaller angular misalignment range and lower torque capacity compared to other coupling types. Oldham couplings see common use in robotics, printers, and other applications requiring electrical insulation between shafts.