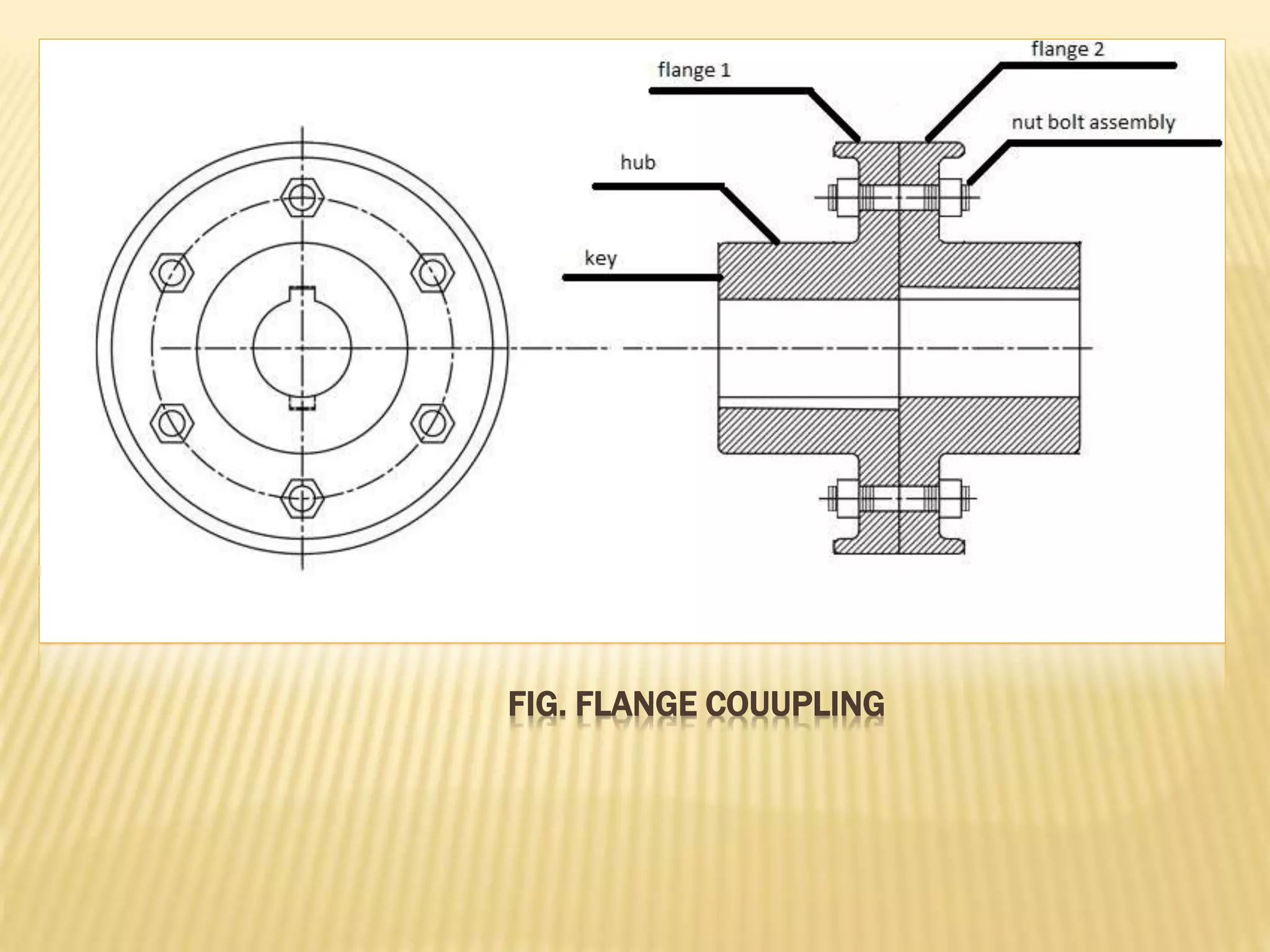

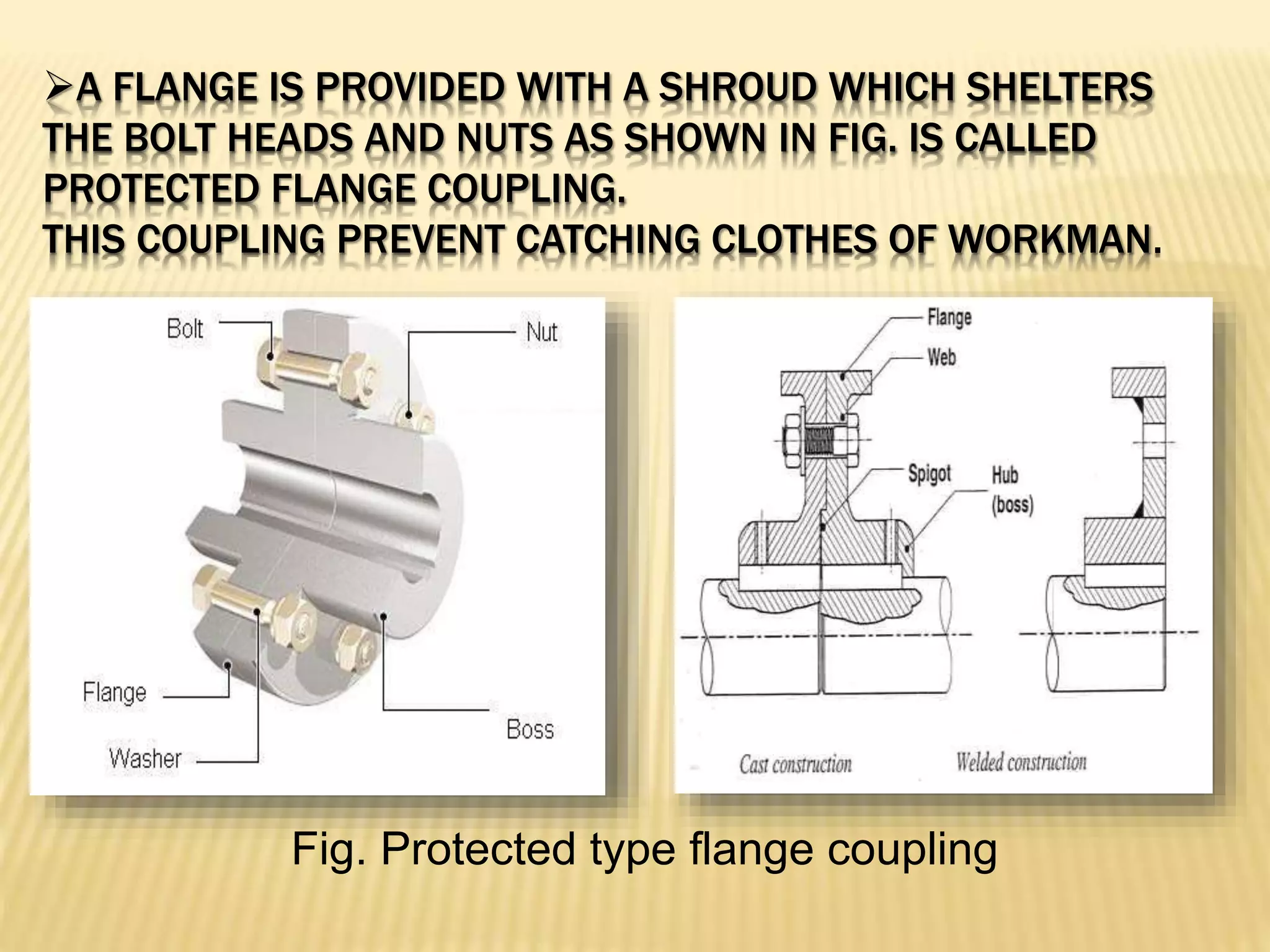

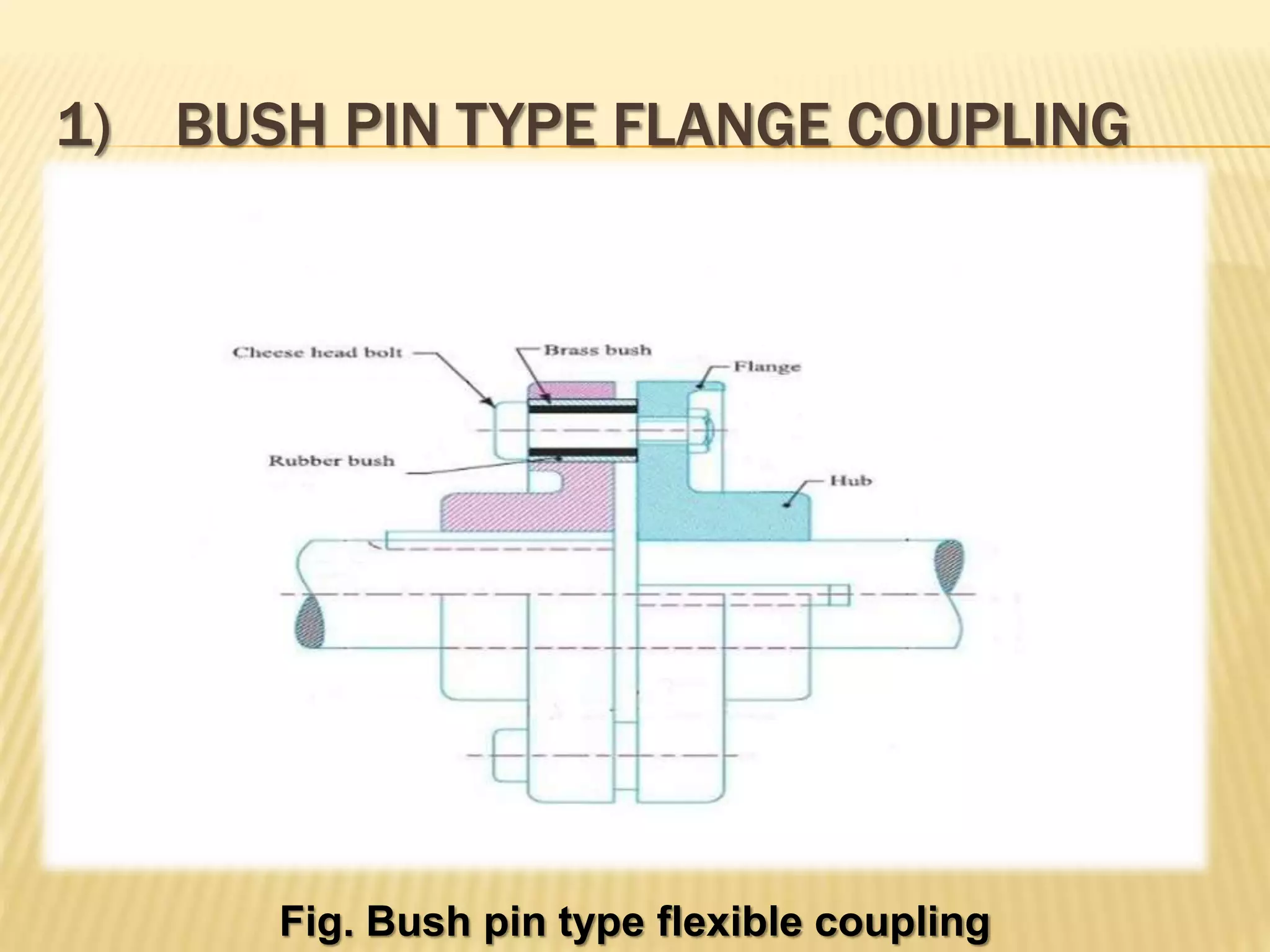

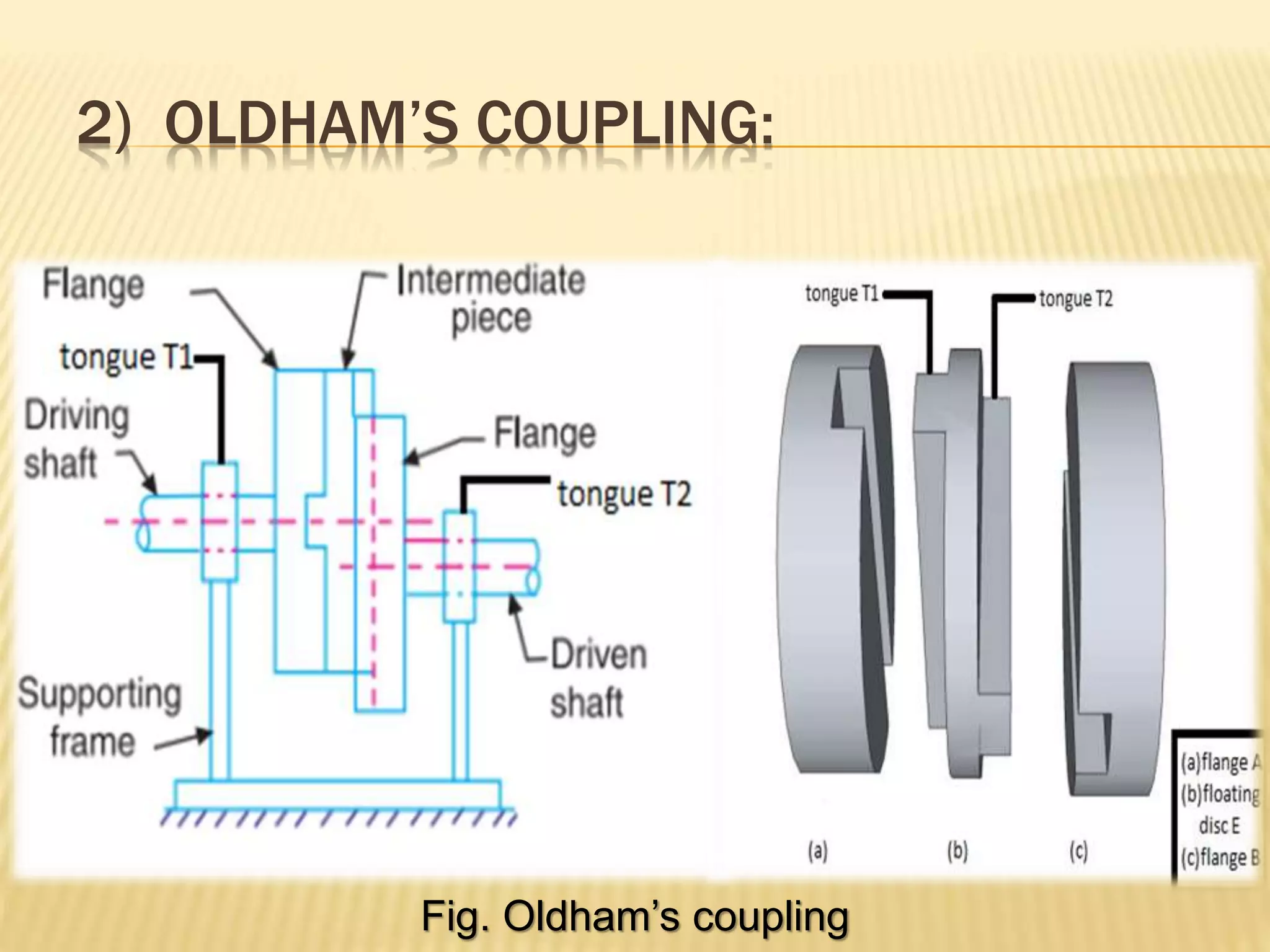

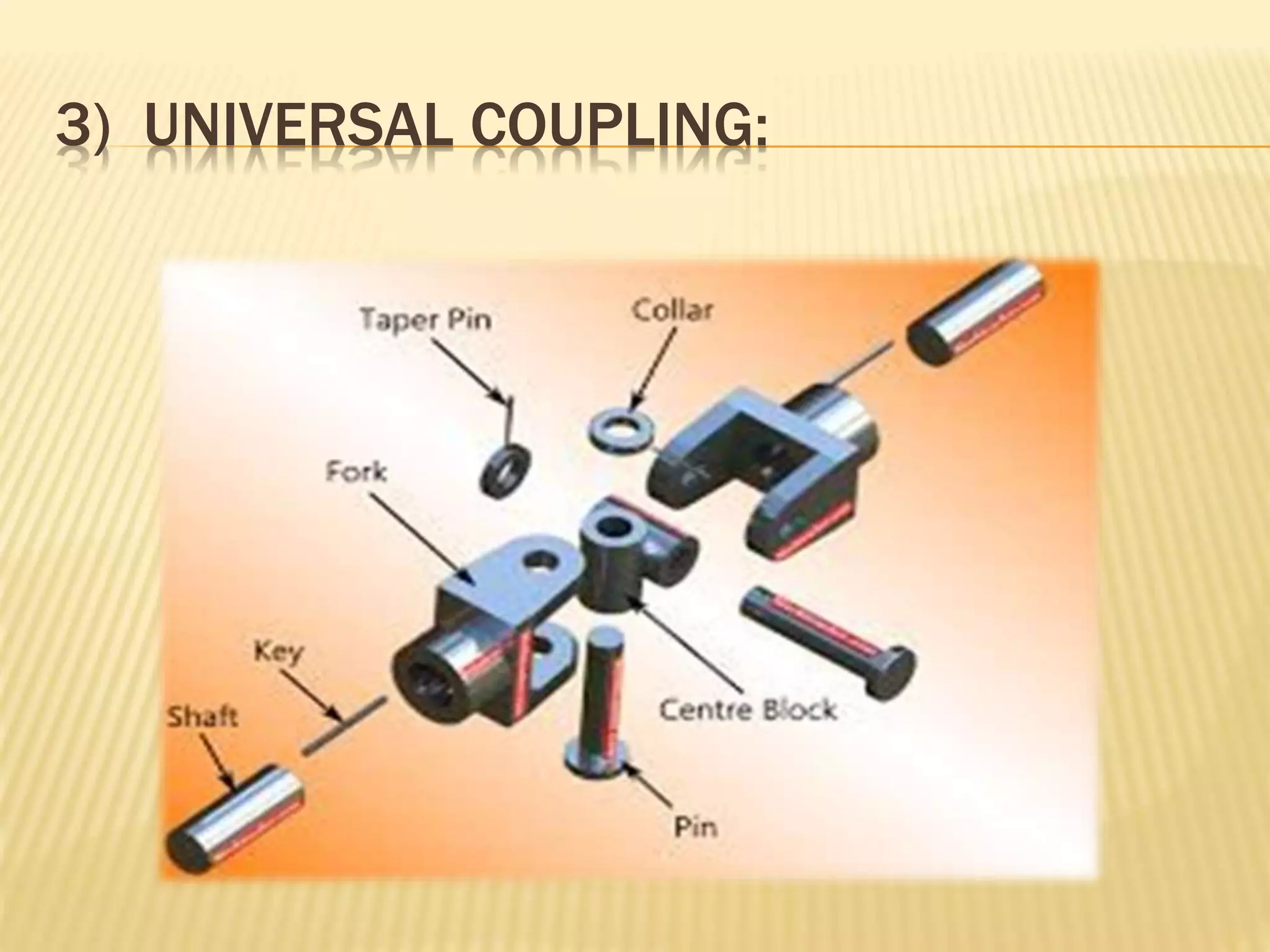

This document discusses different types of couplings used to connect shafts, including flange couplings, flexible couplings, and universal couplings. Flange couplings connect shafts using bolted flanges for rigid connections. Flexible couplings, like bushing pin couplings, allow for misalignment using rubber or leather bushes. Oldham couplings connect parallel shafts with small offsets using a central floating disc with perpendicular tongues. Universal couplings connect intersecting shafts using a central block with perpendicular arms.