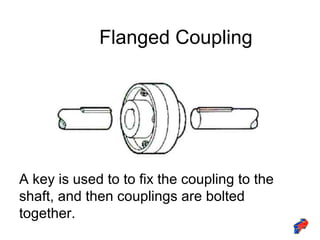

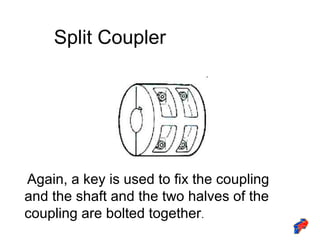

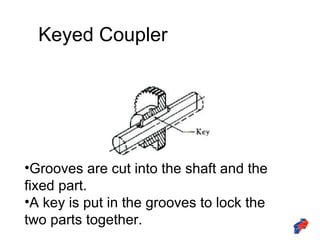

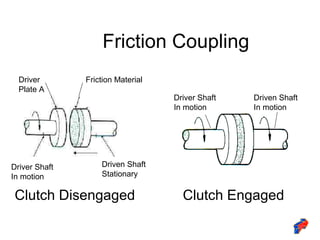

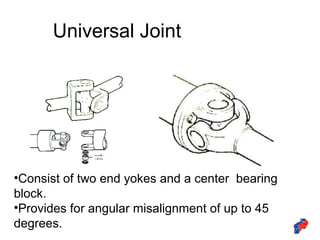

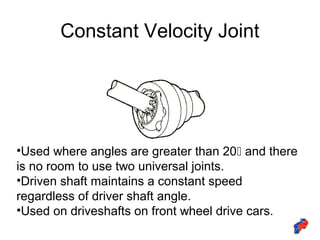

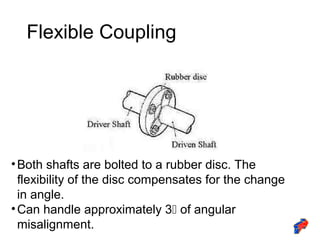

The document discusses different types of couplings used to connect shafts for power transmission. It describes rigid couplings like flanged, split, keyed, and friction couplings which are used for aligned shafts. It also describes flexible couplings like universal joints, constant velocity joints, and flexible couplings that allow for non-aligned shafts and compensate for changes in angular misalignment between the shafts.