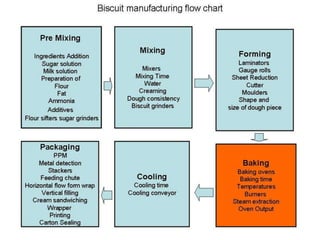

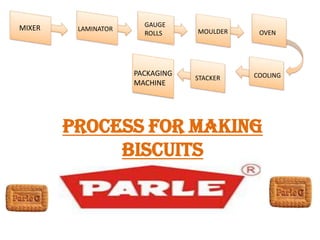

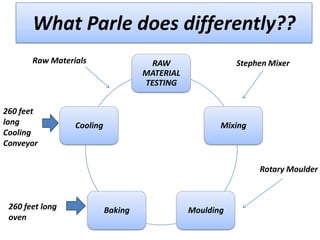

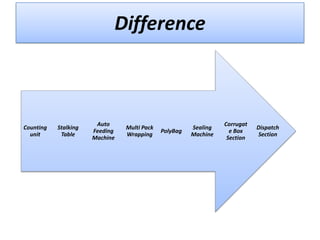

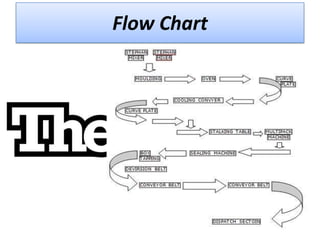

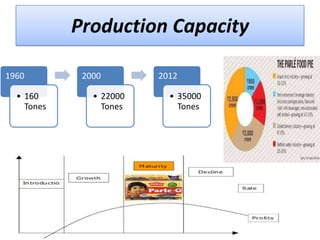

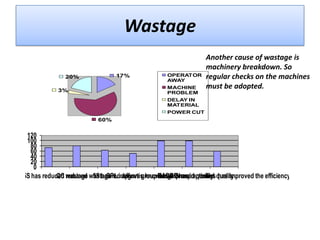

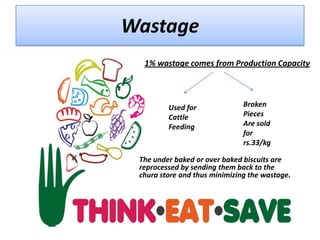

The document outlines the manufacturing process for making biscuits at Parle. Key steps include: mixing raw materials, moulding dough, baking in a 260 foot long oven, cooling on a 260 foot long conveyor, packaging, and dispatching finished biscuits. Parle aims to minimize wastage at each step and ensures quality through processes like HACCP and regular staff training. The production capacity has increased from 160 tons in 1960 to 35,000 tons currently.