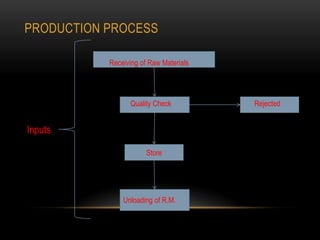

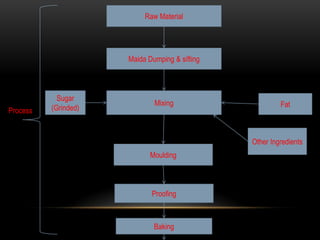

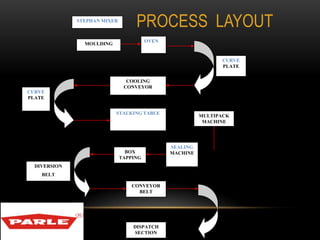

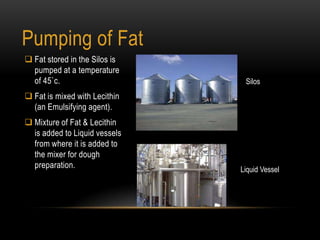

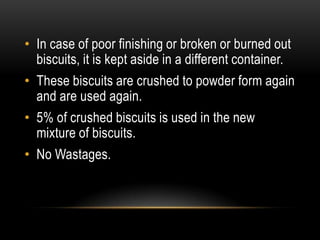

Parle Products is India's largest manufacturer of biscuits and confectioneries with over 80 years of operations. They produce many popular biscuit and snack brands like Parle-G, Hide and Seek, Krackjack, and Monaco. The document outlines Parle's production process which involves receiving raw materials, mixing ingredients, moulding dough, baking biscuits in large oven tunnels, cooling, packaging, and dispatching finished products. Quality checks are performed throughout and defective biscuits are recycled back into the production process to minimize waste.

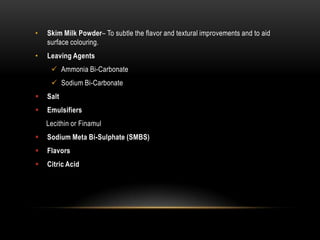

![• Skim Milk Powder

• Leaving Agents

• Salt

• Emulsifiers

• SMBS

• Flavors

• Citric Acid

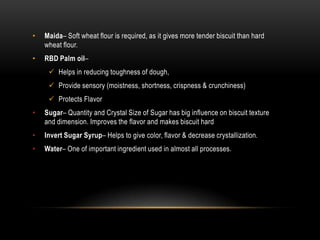

• Wheat Flour (Maida)

• Fat (RBD Palm Oil)]

• Sugar

• Invert Sugar Syrup

• Water

INGREDIENTS

Major Minor](https://image.slidesharecdn.com/technologymanagement-parleproducts-140407041233-phpapp02/85/Technology-management-parle-products-5-320.jpg)