Embed presentation

Downloaded 16 times

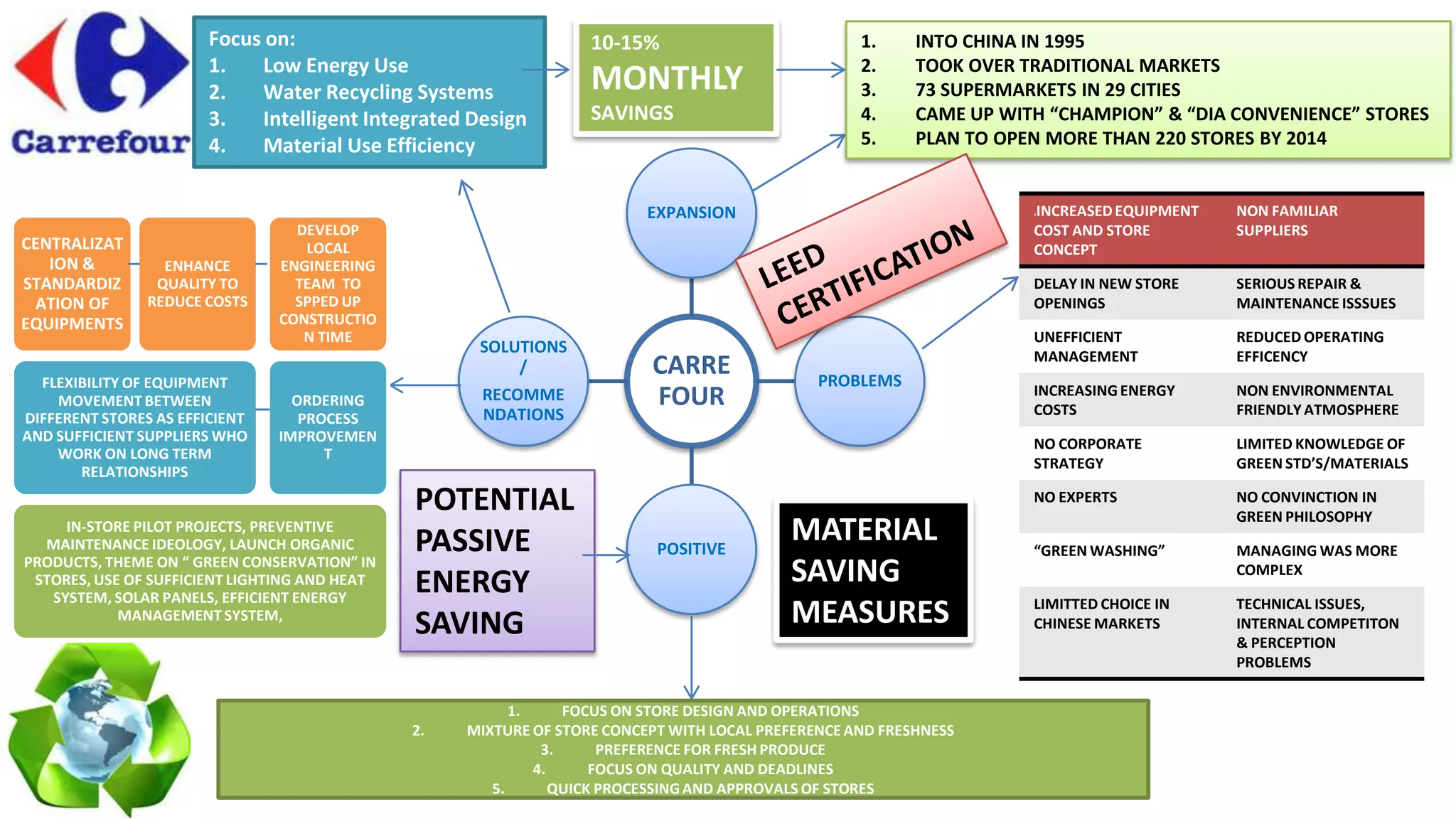

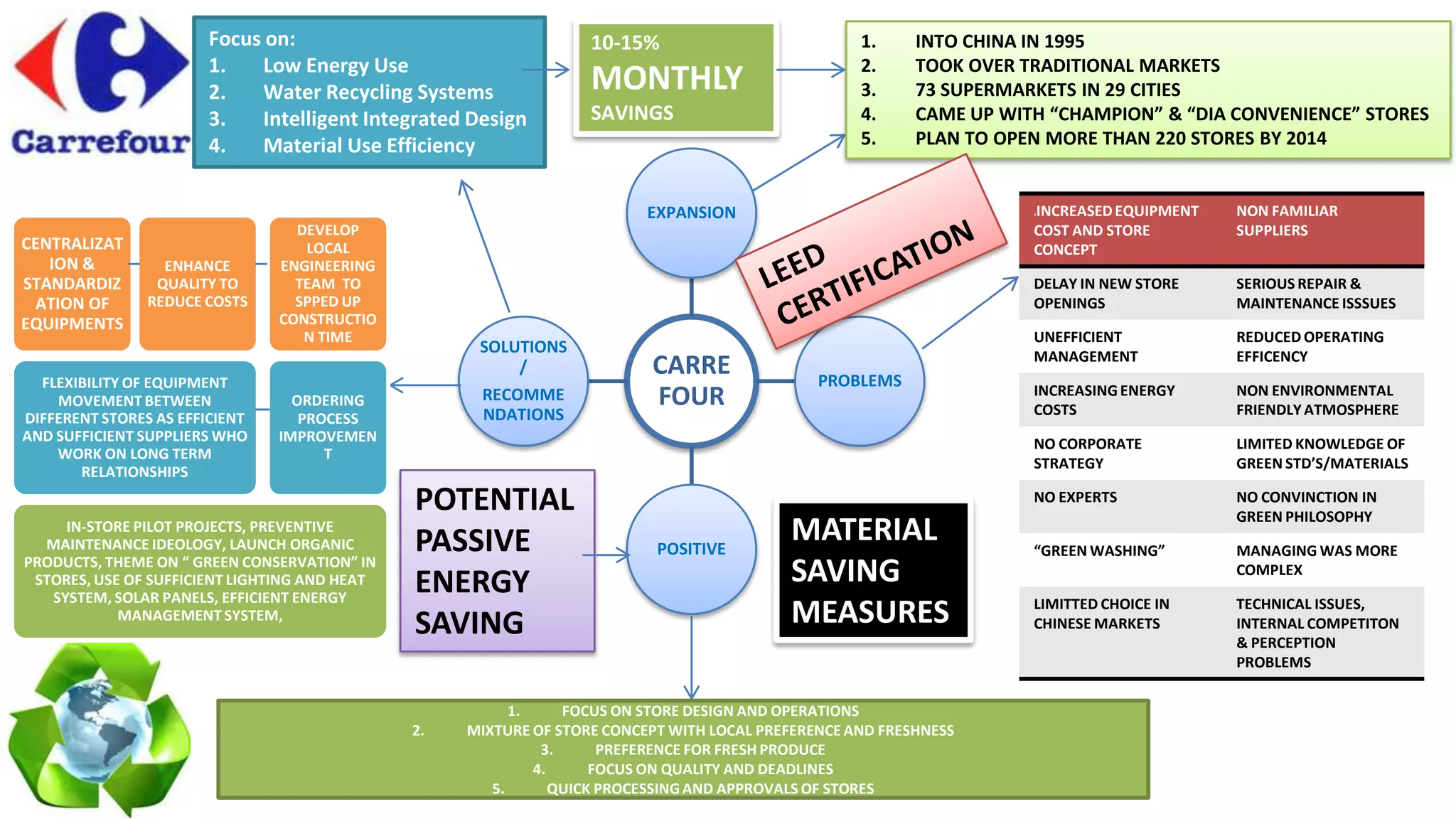

Carrefour, a French supermarket chain that expanded into China in 1995, faced several problems with their expansion including increased equipment and store concept costs, supply issues, and inefficient management. They also struggled with reducing operating efficiency, increasing energy costs, and lack of environmentally friendly practices. The document recommends Carrefour focus on store design and operations, integrating local preferences, and improving quality, deadlines, and approval processes. It suggests initiatives like pilot green projects, preventative maintenance, organic products, and using solar panels and efficient energy systems to address issues and increase sustainability.