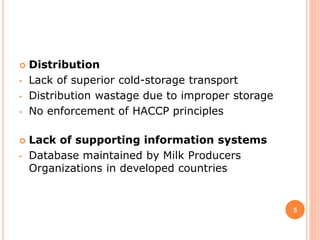

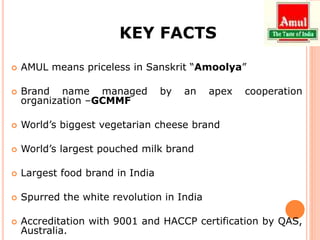

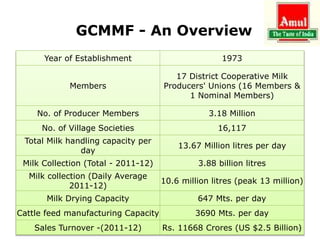

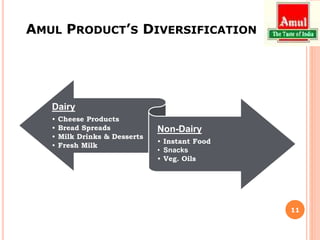

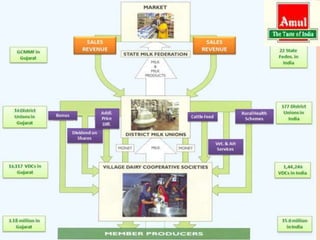

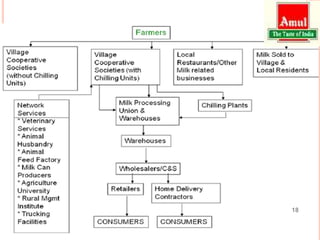

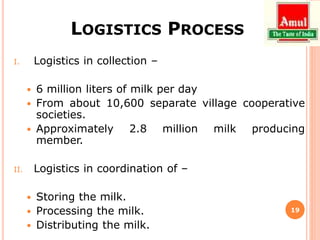

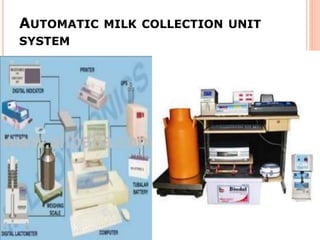

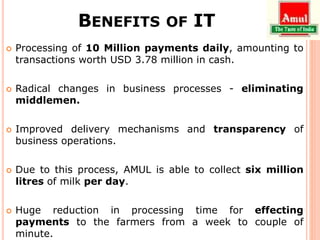

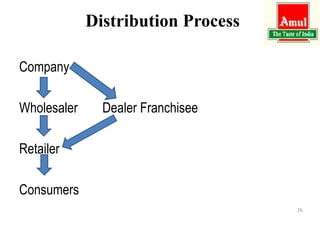

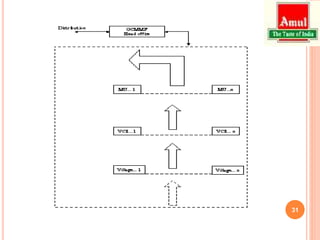

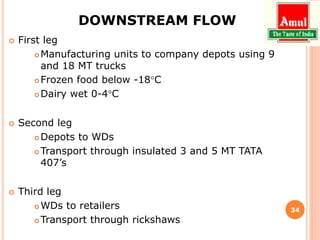

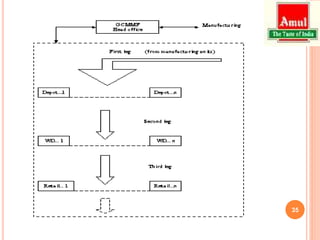

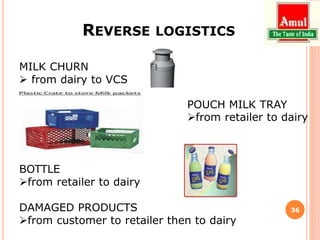

The document presents on the distribution network management of Amul. It discusses Amul's procurement process which involves collecting milk from village cooperative societies twice a day and transporting it for processing. It then discusses Amul's distribution channel which involves transporting processed milk and dairy products from manufacturing units to depots and warehouses, and then to retailers using insulated vehicles. It also discusses Amul's plans to expand direct retailing through franchise-owned stores.