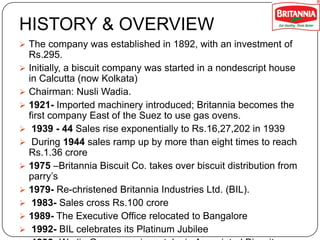

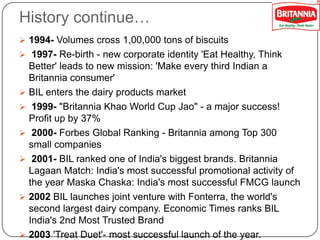

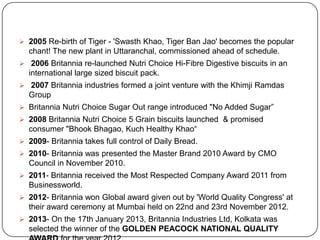

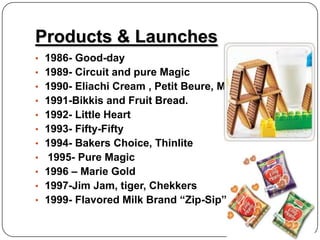

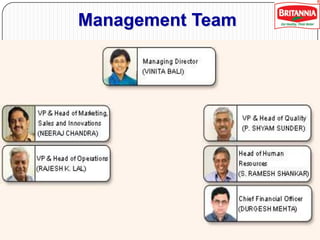

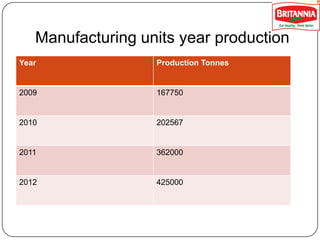

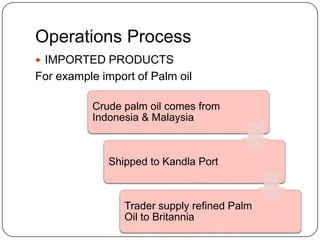

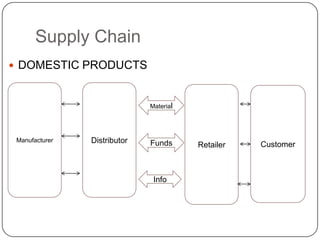

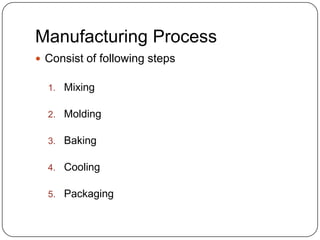

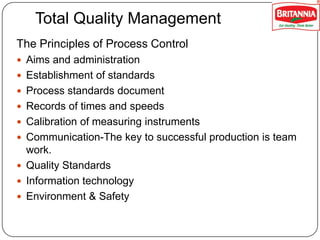

The document provides an overview of Britannia, an Indian food company established in 1892. It details Britannia's vision to dominate the Indian food market with "Tasty Yet Healthy" products. The document outlines Britannia's history and major product launches. It also describes the company's manufacturing process, quality management, and goals to be a leading low-cost producer while maintaining quality.