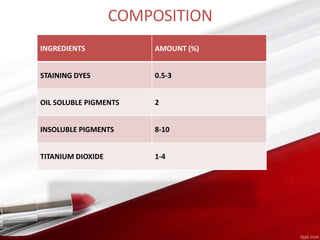

The document provides a detailed overview of lipstick as a cosmetic product, including its composition, how it works, and its characteristics. It discusses the manufacturing process, common formulation-related problems, and evaluation parameters for quality control. Key ingredients such as waxes, oils, colors, and additives are highlighted, along with the critical importance of color and safety in lipstick formulation.