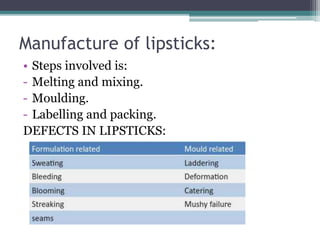

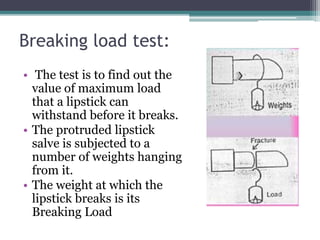

The document discusses the characteristics, composition, manufacturing process, evaluation, and facts about lipsticks. Lipsticks are dispersions of coloring matter in a base containing oils, fats, and waxes, and should be smooth to apply, have good indelibility and color intensity, and remain firm during storage. They are manufactured by melting and mixing the wax, oil, dye, and additive components, then molding and packaging the lipsticks. Evaluation methods include testing the color, melting point, softening point, microbial levels, and break strength.