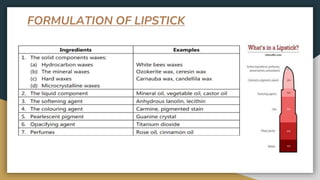

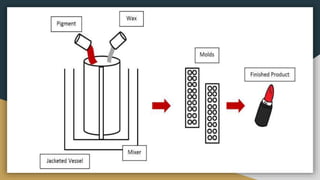

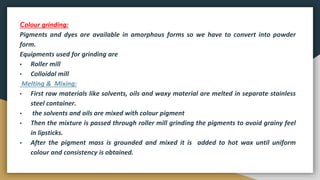

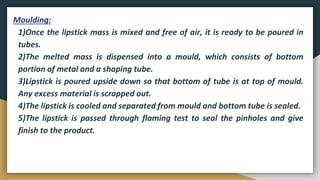

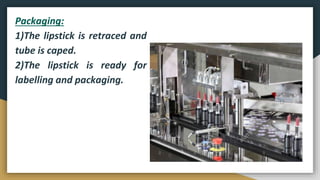

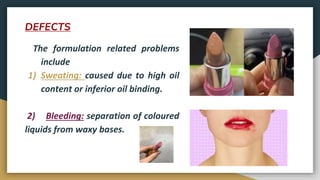

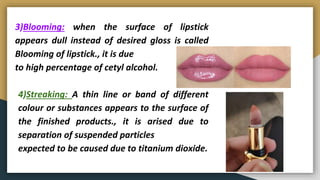

The document provides a detailed overview of lipsticks, including their definition, composition, advantages, disadvantages, and manufacturing processes. It emphasizes key components such as waxes and oils, their roles in formulation, and the potential defects and evaluations for lipstick products. Additionally, it cites references for further reading on cosmetic formulations.