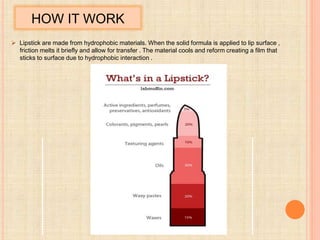

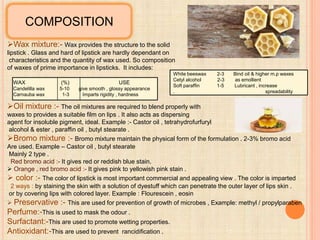

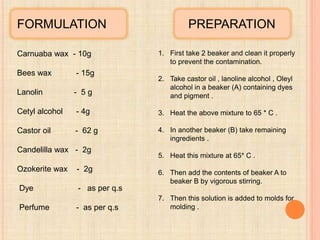

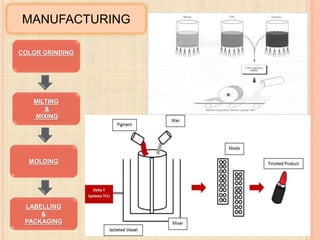

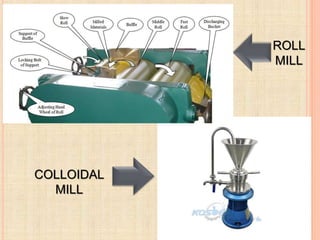

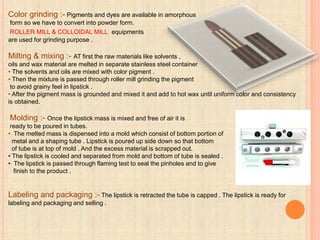

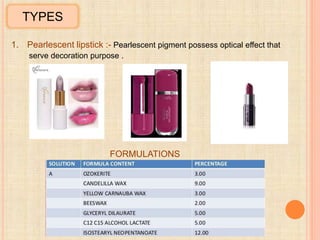

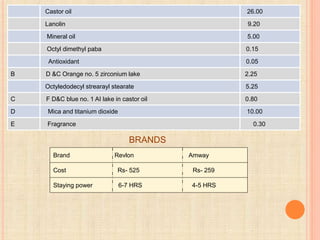

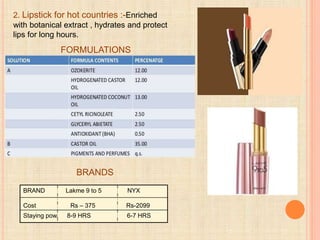

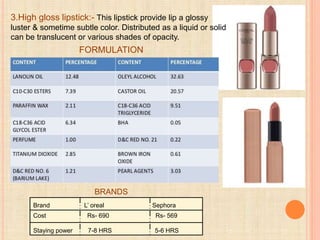

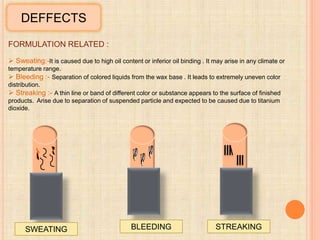

Lipstick is a cosmetic product made from pigments, oils, waxes, and emollients that is applied to lips for color, moisturization, and protection. The ideal lipstick has properties like being non-toxic, stable, and resistant to grittiness, with a formulation involving various types of waxes, oils, and preservatives. Manufacturing involves processes such as color grinding, mixing, molding, and packaging, with types including pearlescent, high gloss, and liquid lipsticks, each designed for different effects and markets.