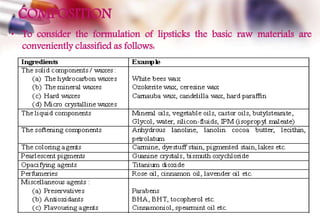

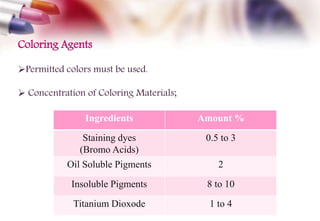

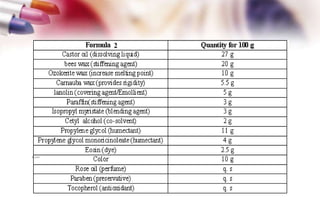

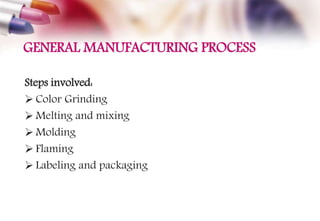

This document provides information on lipstick, including its definition, characteristics, composition, manufacturing process, potential defects, and evaluation methods. Lipstick is defined as a dispersion of coloring matter in a base of oils, fats, and waxes molded into a stick. It aims to impart attractive color and gloss to lips while preventing drying and cracking. The composition includes waxes, oils, coloring agents, preservatives, and fragrances. Potential defects include sweating, bleeding, and streaking. Lipstick is evaluated based on color consistency, melting point, softening point, microbial contamination, rancidity, breaking load, and rupture strength.