"Welcome to my SlideShare space dedicated to the world of cosmetics, beauty, and skincare. Here you’ll find insightful presentations on the latest trends, product innovations, makeup techniques, and self-care routines. My goal is to share knowledge that empowers individuals to feel confident, radiant, and informed about the products they use.

From natural skincare remedies to modern cosmetic science, I cover a wide range of topics designed for beauty enthusiasts, professionals, and learners alike. Whether you’re looking for tips on sustainable beauty, exploring new product launches, or understanding the science behind cosmetics, this page is your go-to resource.

Follow along to discover presentations that inspire, educate, and celebrate the art of beauty."

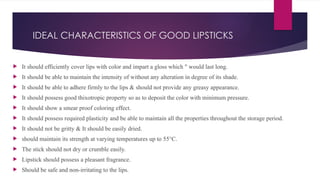

![FORMULATION OF TOOTHPASTES

Gelling / Binding Agents

The binding agents are used in order to hold the solid and the liquid components

together to form a smooth paste and maintain its property, particularly during storage.

The commonly used binding agents are cellulose derivatives such as Carboxy Methyl

Cellulose (CMC), Sodium Carboxy Methyl Cellulose (SCMC), Hydroxyethy] cellulose,

Cellulose ethers etc.](https://image.slidesharecdn.com/5cosmetics-251229050707-90f05ddc/85/Industrial-Pharmacy-Unit-V-Cosmetics-pptx-38-320.jpg)