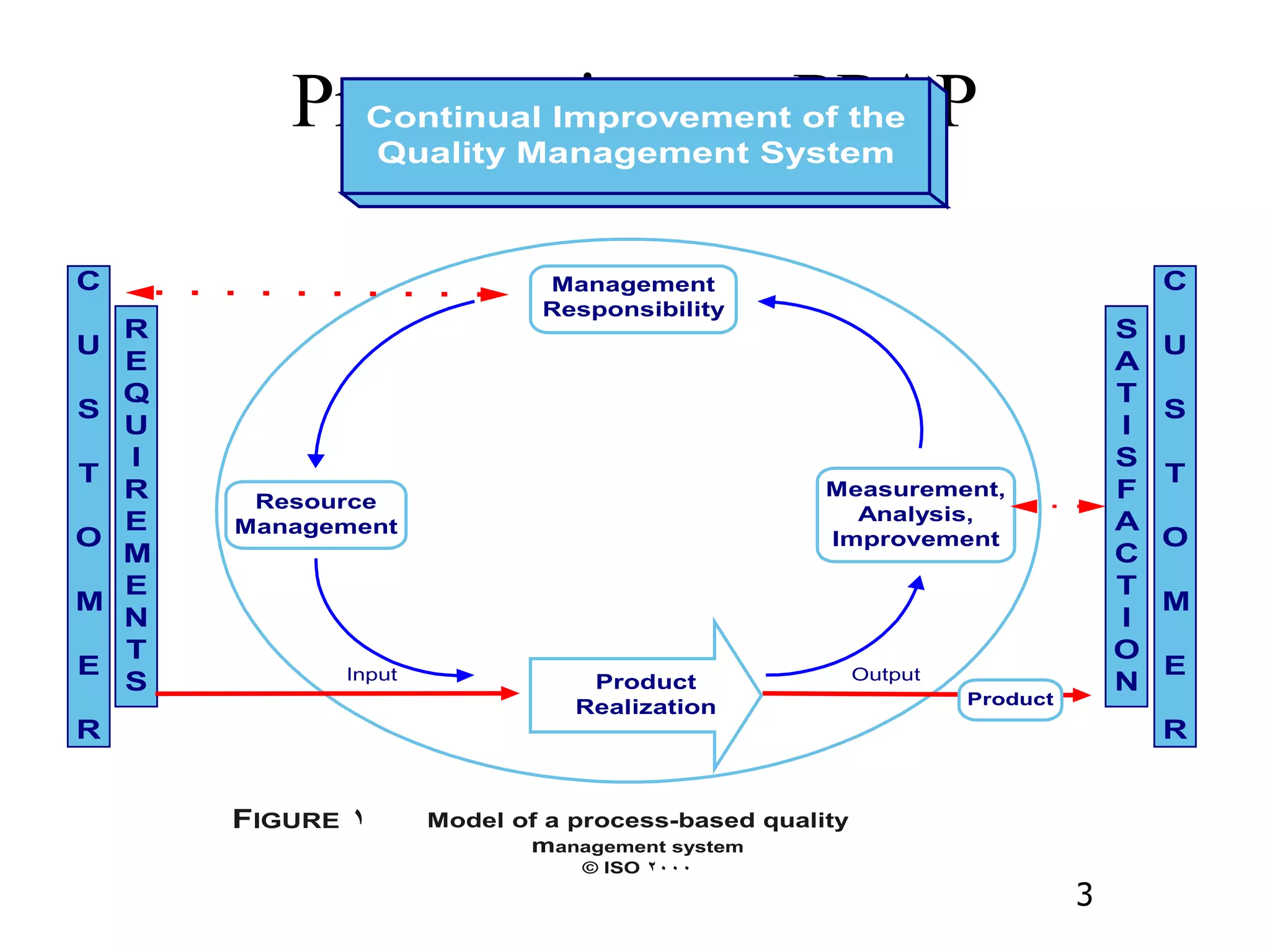

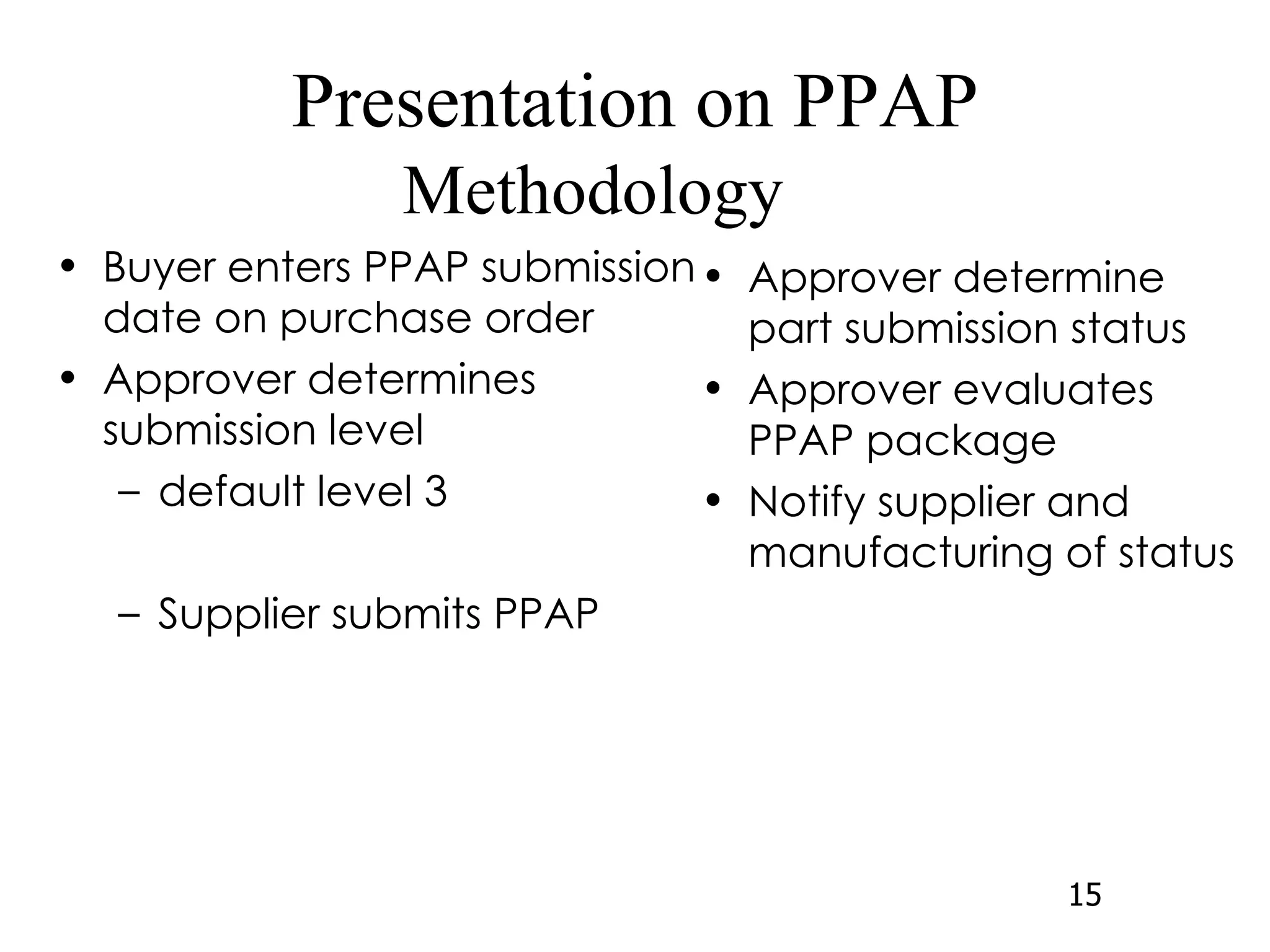

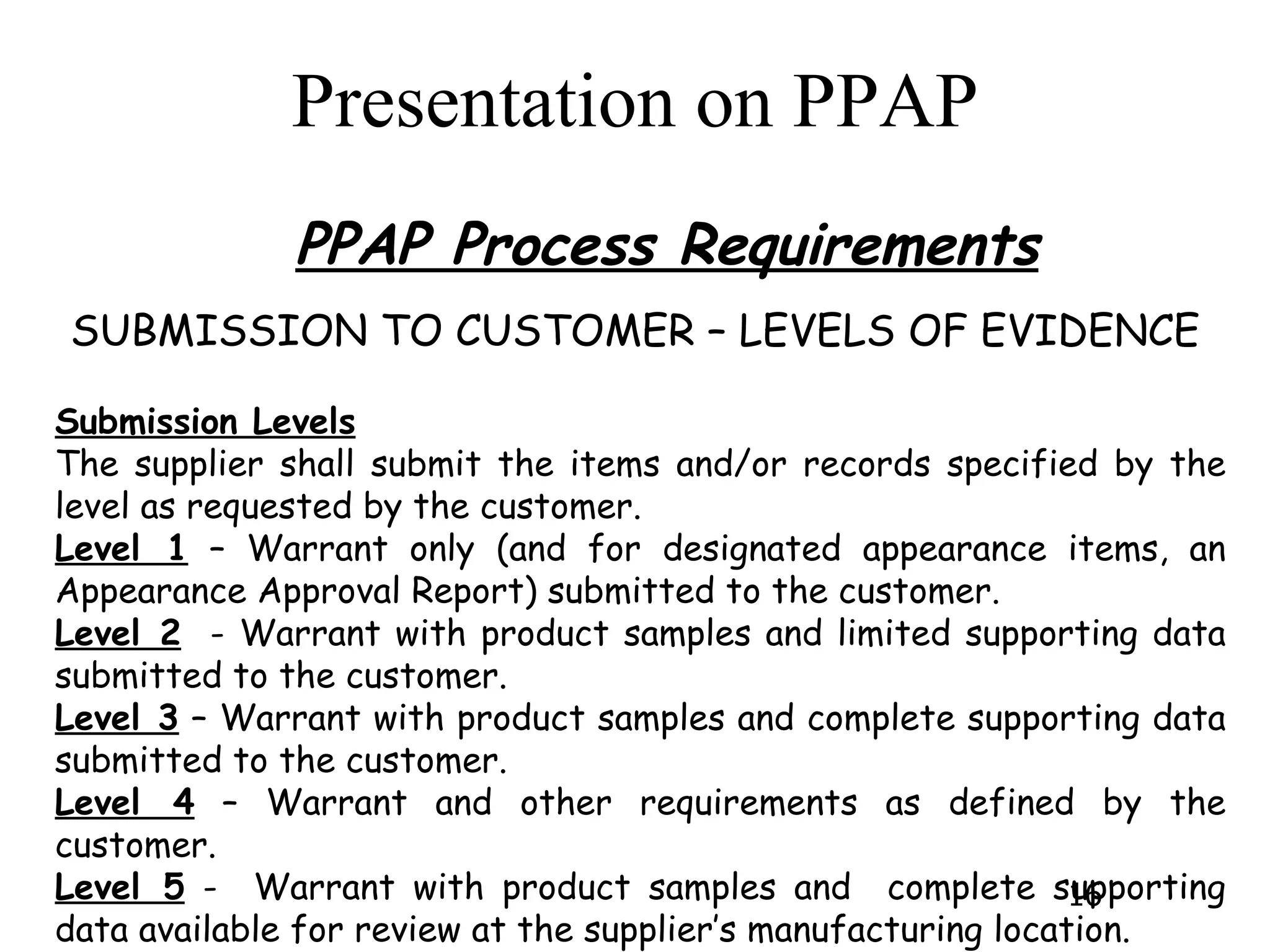

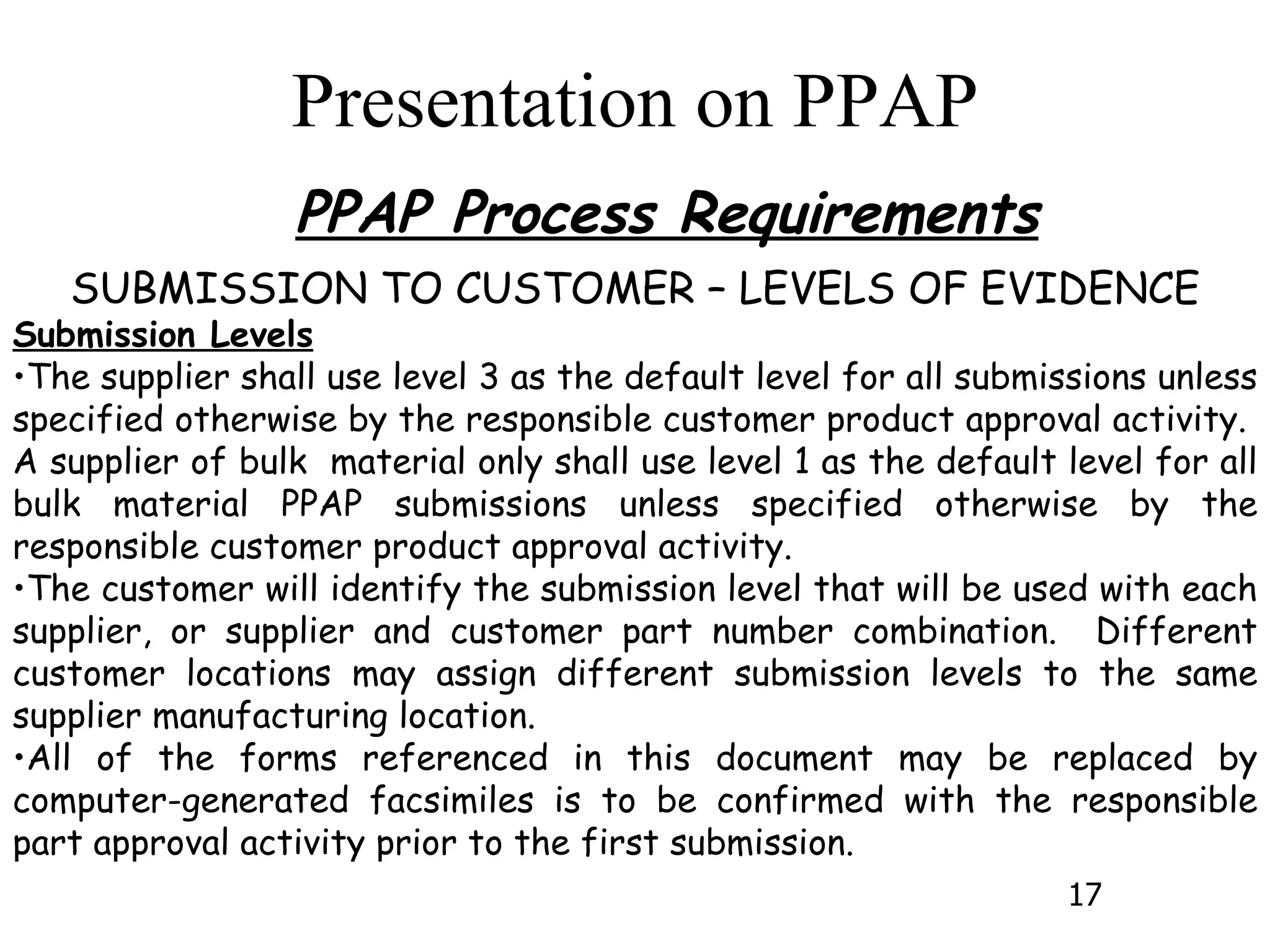

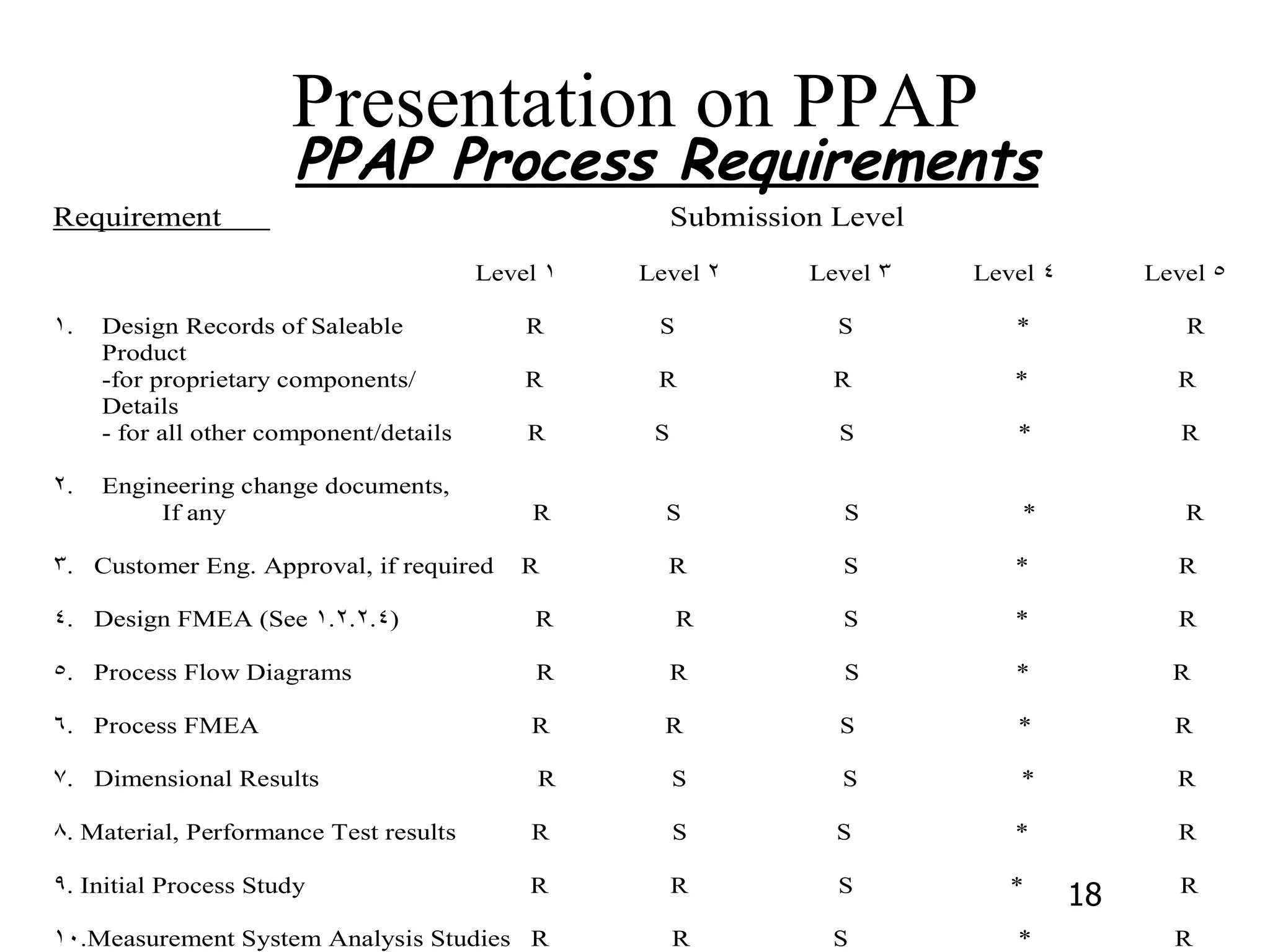

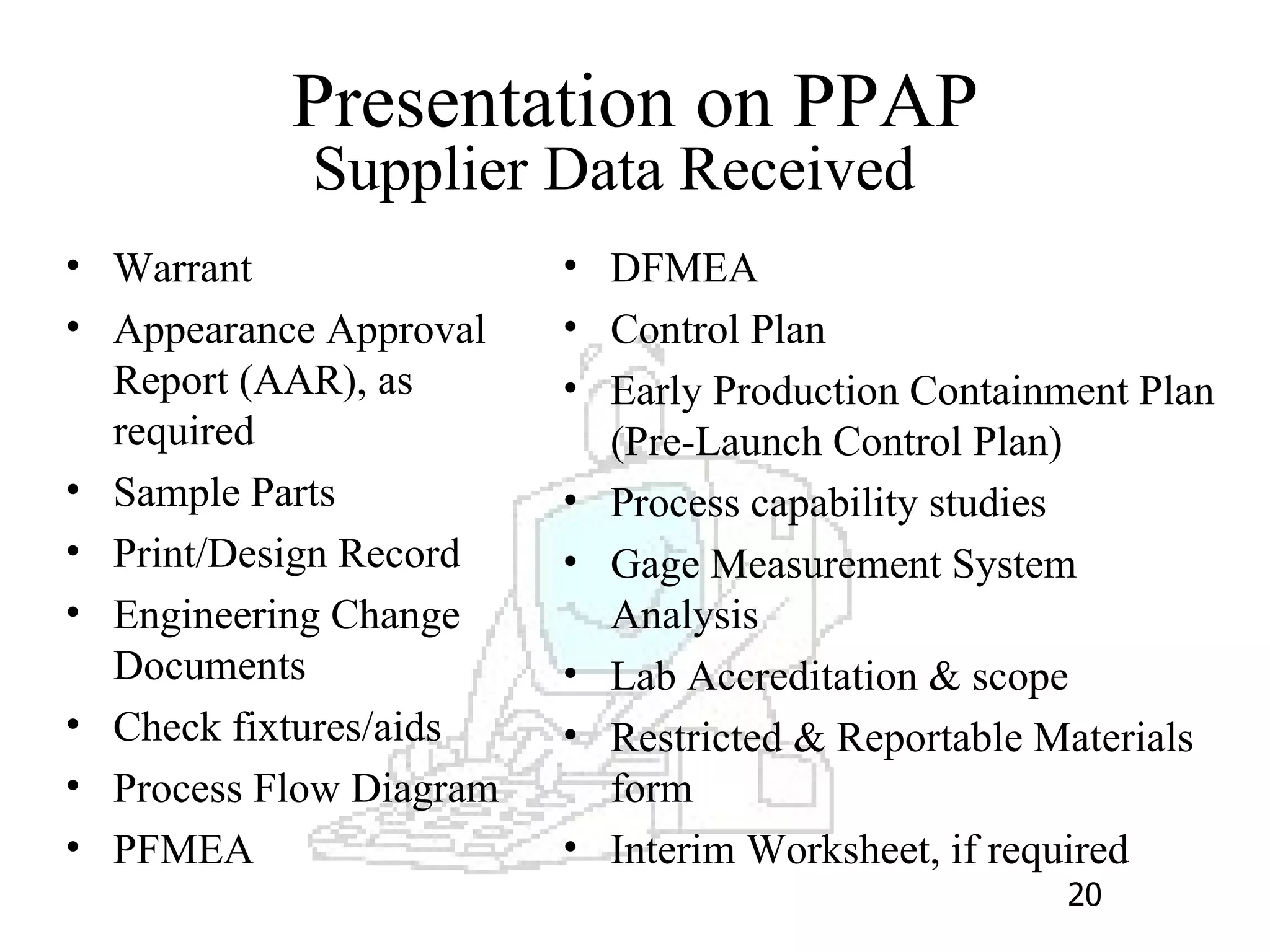

The document discusses the Production Part Approval Process (PPAP), including when PPAP submissions are required, the different submission levels, and the forms and documents required for each submission level. A PPAP submission is needed for new parts, design or process changes, changes in suppliers, inactive tooling, and more. The default submission level is level 3, which requires samples, supporting data, a design record, a process flow diagram, and more. Level 1 requires only a warranty, while level 2 adds limited data and samples.