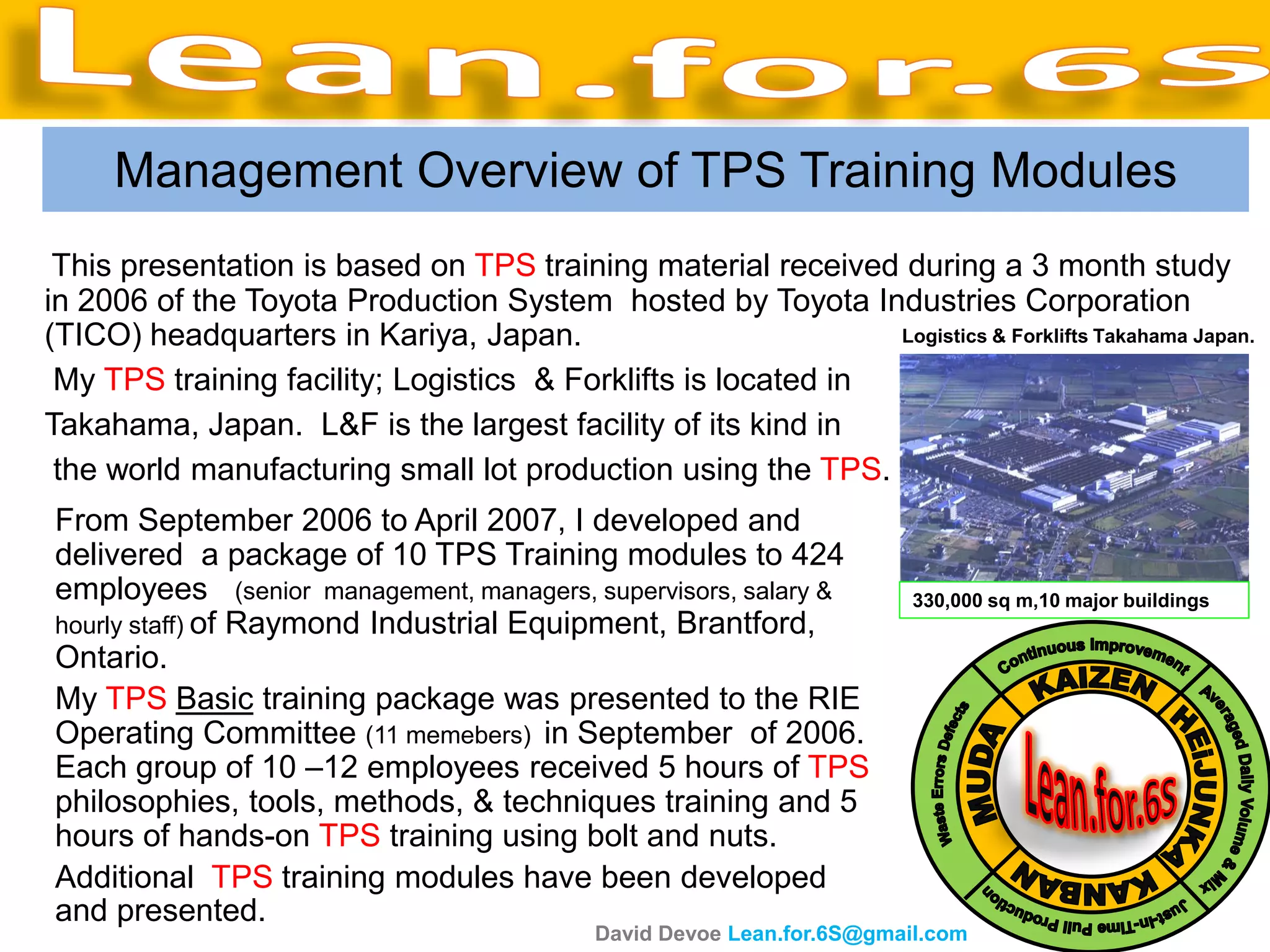

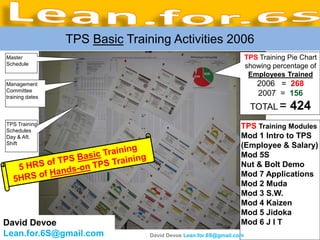

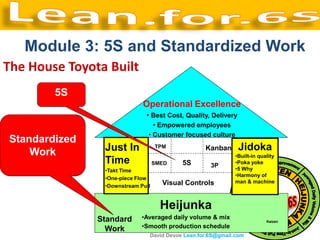

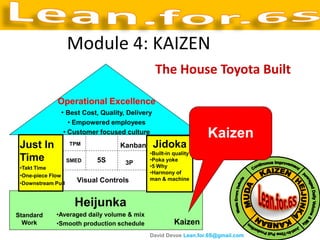

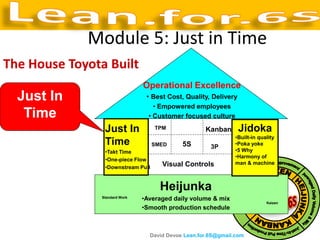

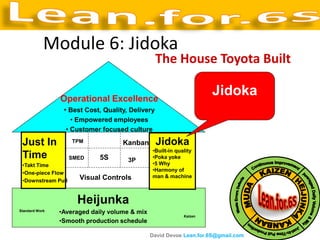

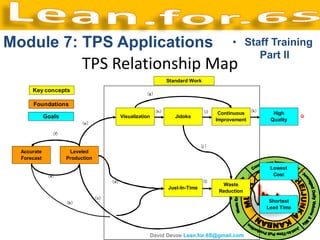

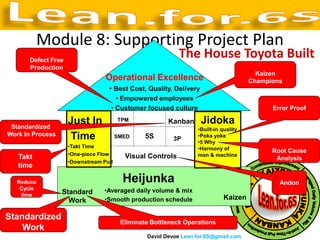

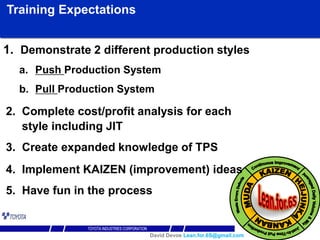

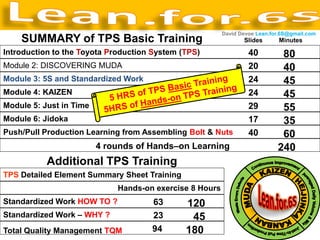

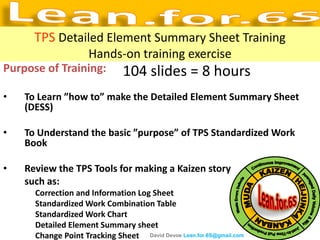

This document provides an overview and summary of TPS training modules delivered to employees of Raymond Industrial Equipment. The training included 10 modules covering topics such as introductions to TPS philosophies and tools, 5S, standardized work, Kaizen, Just in Time, and Jidoka. Hands-on exercises were also conducted to demonstrate push and pull production systems. In total, 424 employees received the training between 2006 and 2007. The training aims to develop staff managers' ability to successfully lead change within their respective areas and implement TPS processes.