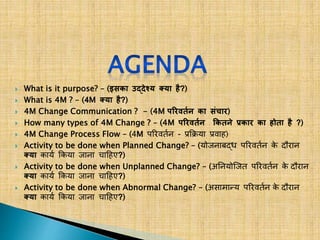

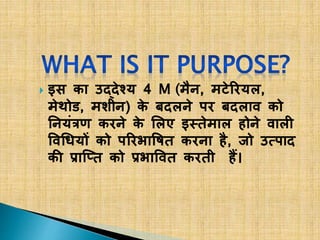

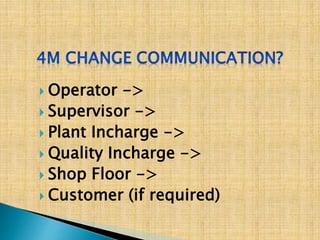

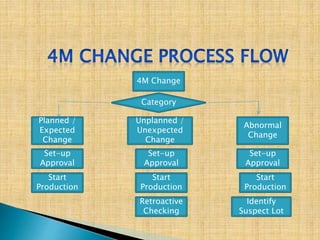

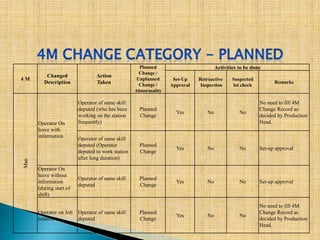

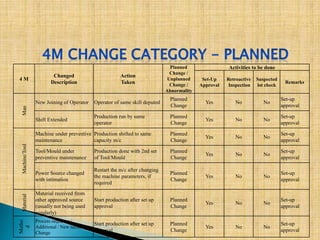

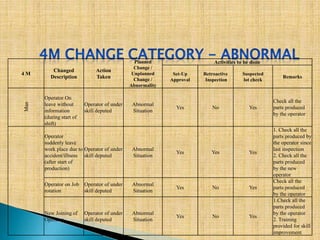

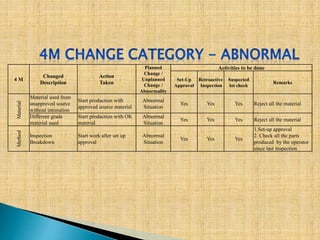

The document discusses 4M change management processes. 4M refers to changes in man, material, machine, or method that can impact product quality. It defines the 4M categories and outlines procedures for planned, unplanned, and abnormal changes. For each change type, it specifies activities like set-up approval, retroactive inspection, and suspect lot checking to control the change and its effects on production. The goal is to effectively manage 4M changes to maintain product quality.