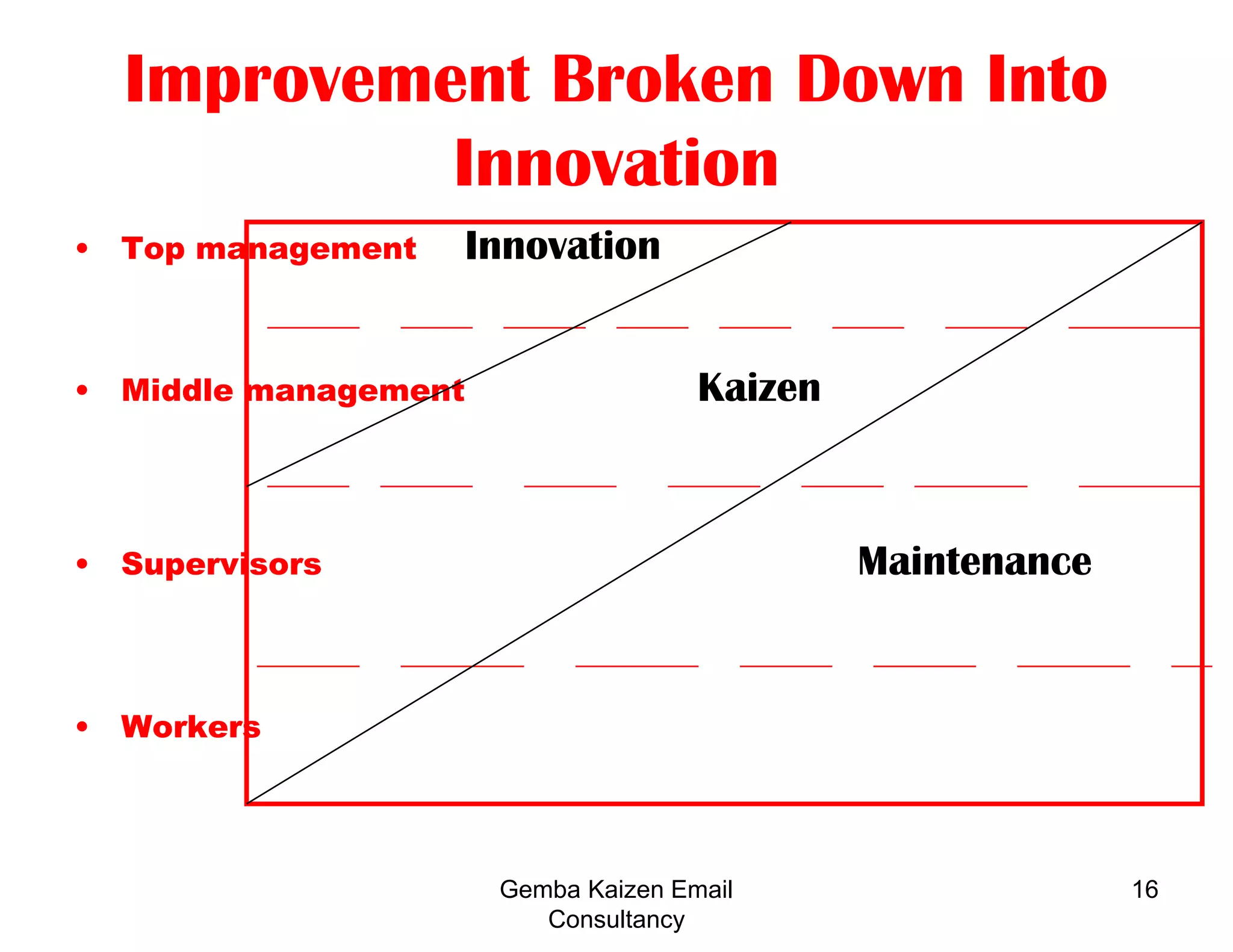

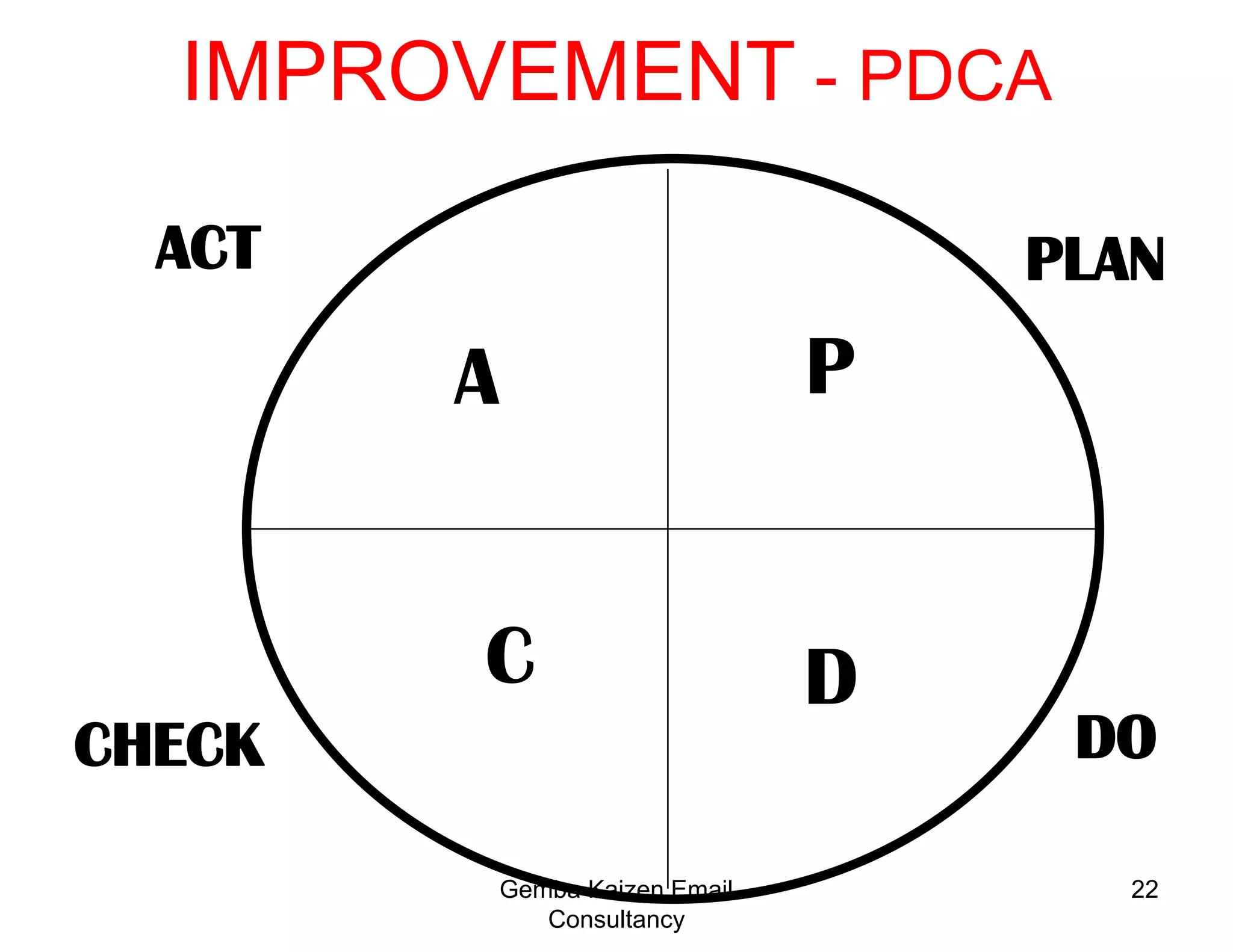

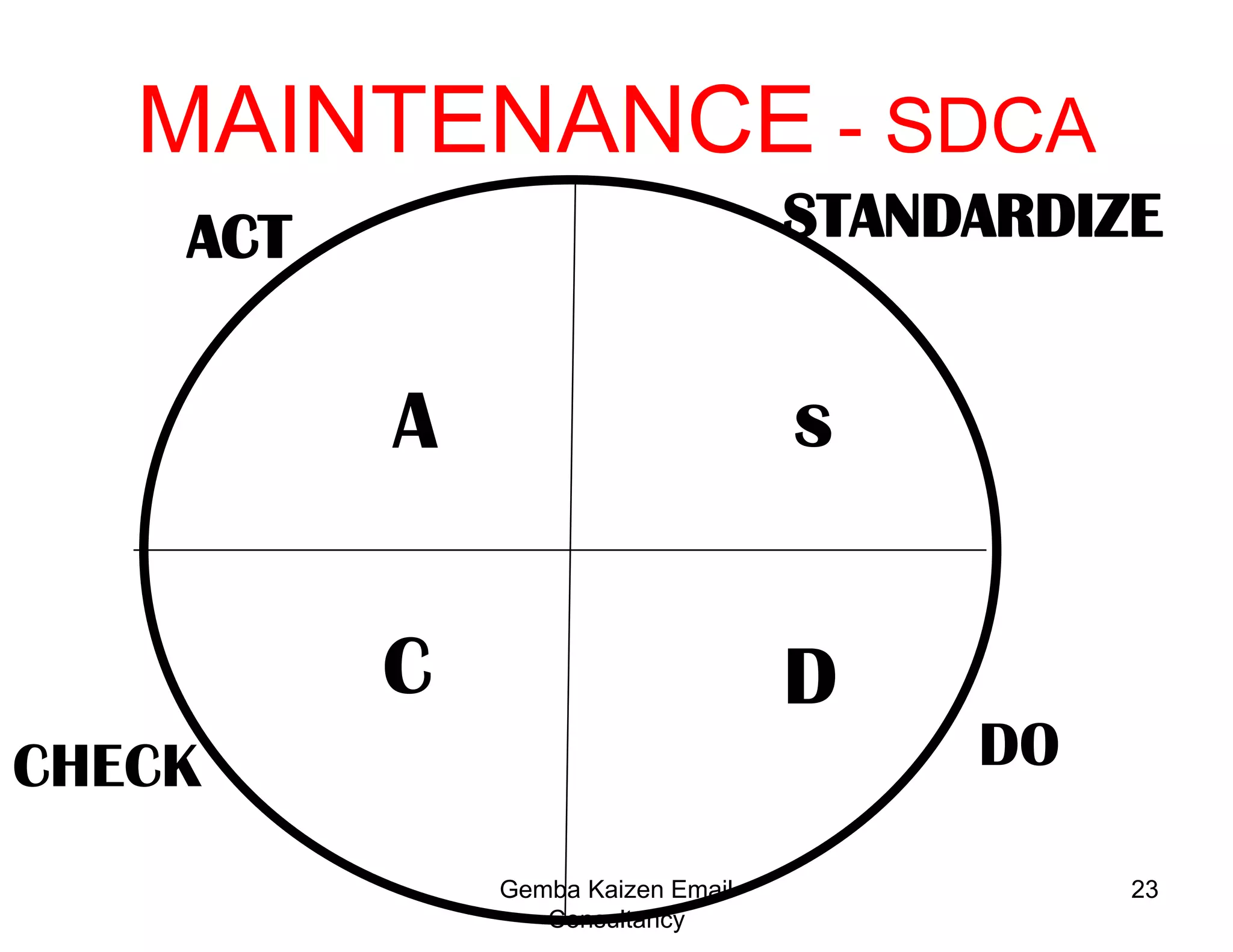

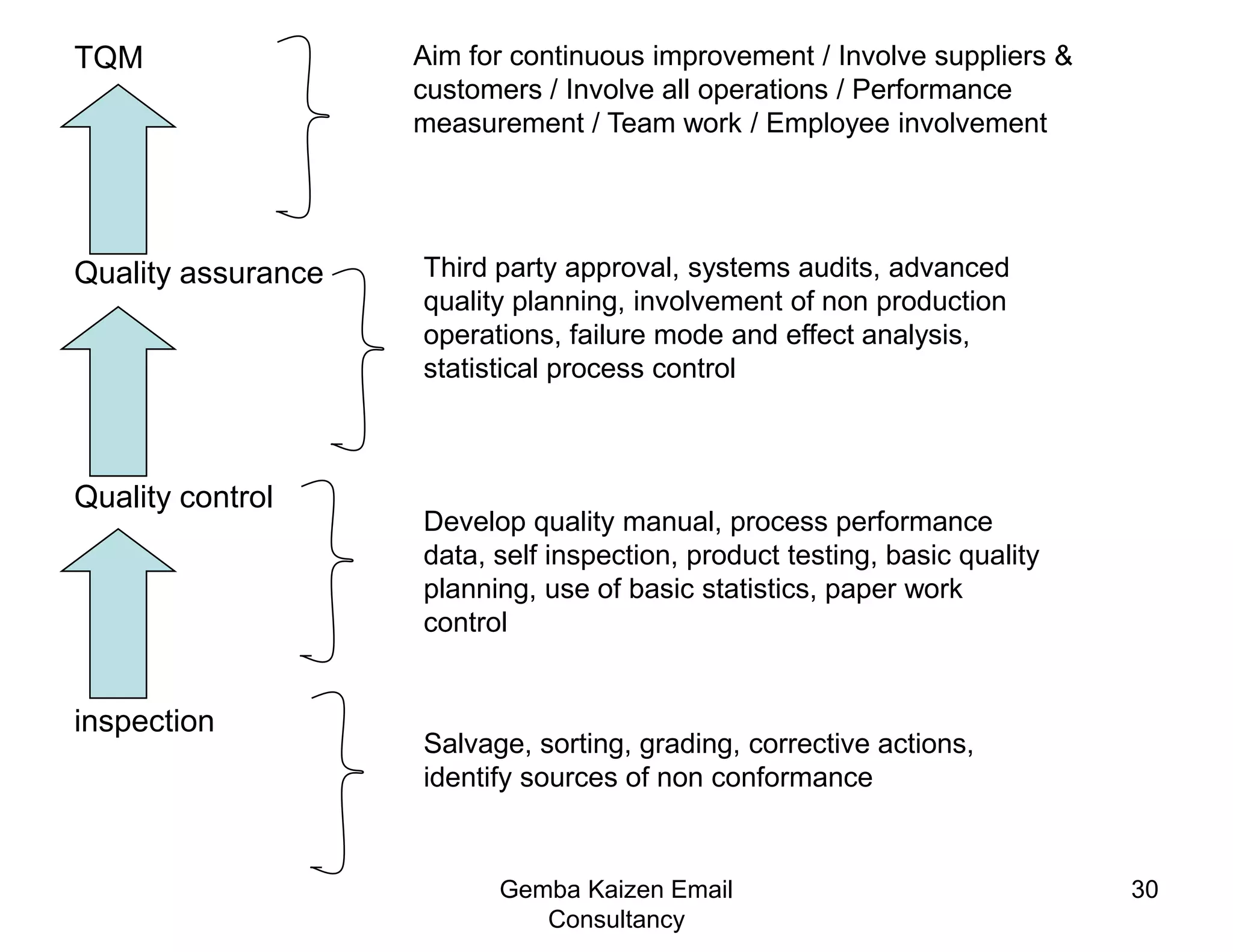

Gemba Kaizen is a philosophy that emphasizes continuous, incremental improvement in processes, originally developed in the Toyota Motor Company. It integrates concepts from lean manufacturing, focusing on waste elimination and creating a culture that prioritizes quality and efficiency. The approach relies on the PDCA (Plan-Do-Check-Act) cycle for process improvement while ensuring management commitment and data-driven decision-making.