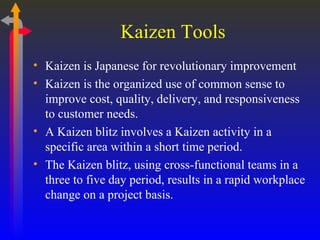

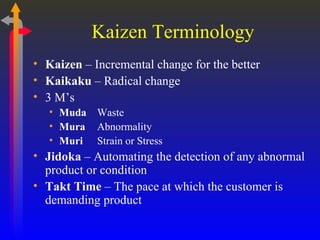

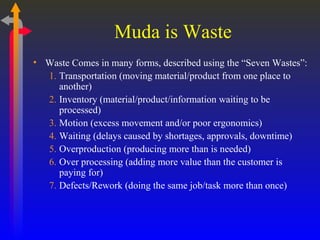

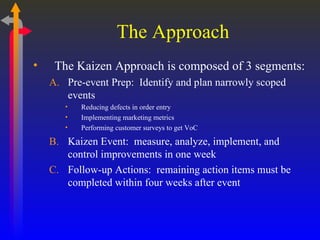

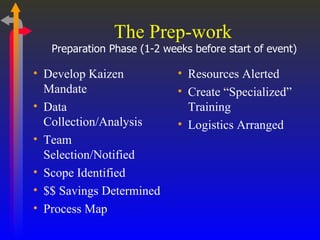

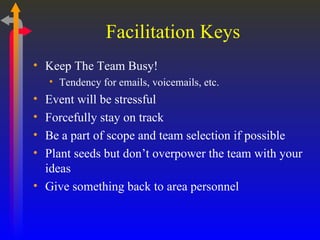

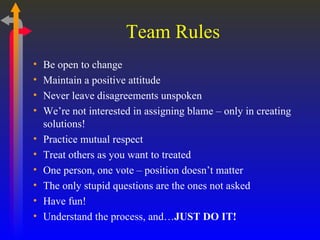

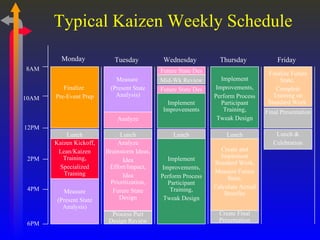

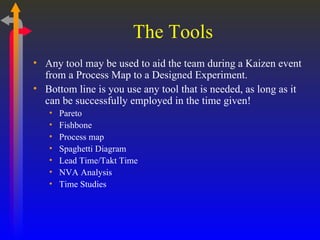

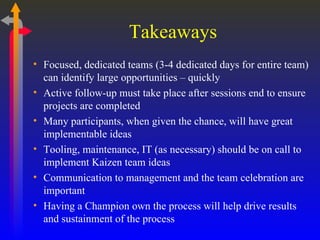

Kaizen is a Japanese philosophy that focuses on continuous incremental improvement of processes in business or industry. A Kaizen blitz involves using cross-functional teams over a short period, like 3-5 days, to rapidly improve a specific work area. The Kaizen approach uses pre-event preparation, a focused Kaizen event, and follow-up actions to implement improvements identified during the event. Tools like process mapping and data analysis are used to identify issues and prioritize solutions, which are then implemented during the event to create standardized work processes and measure benefits.