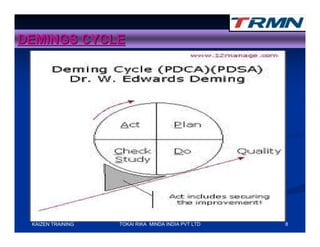

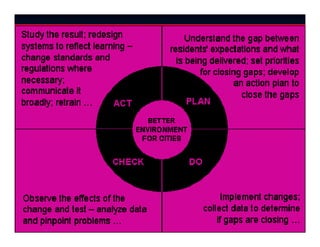

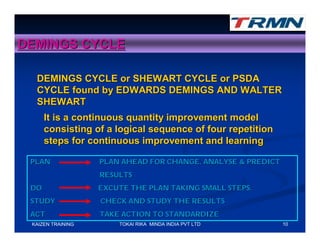

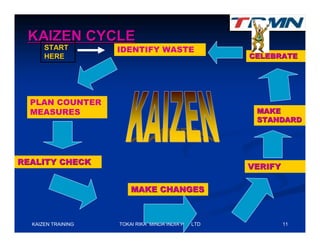

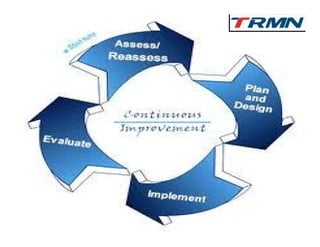

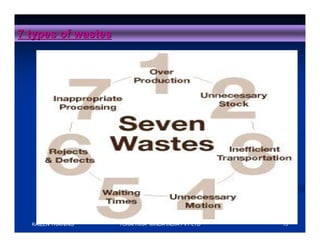

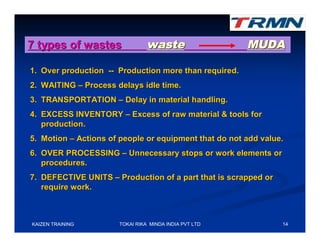

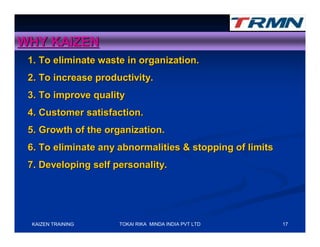

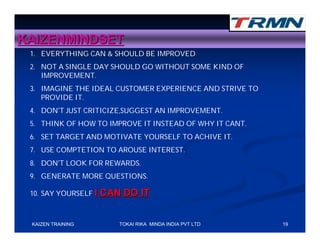

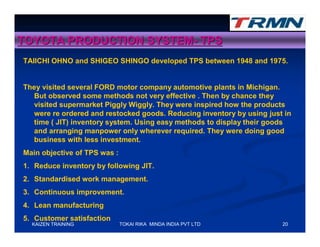

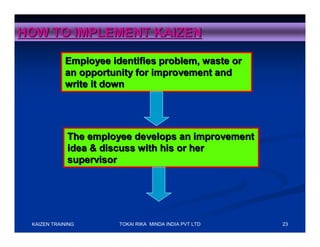

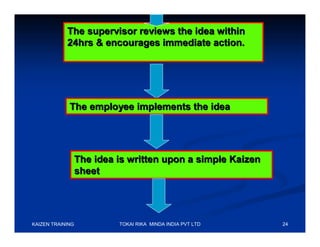

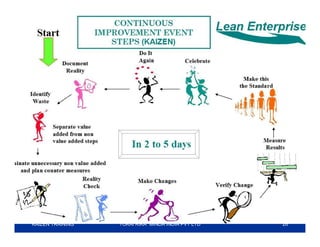

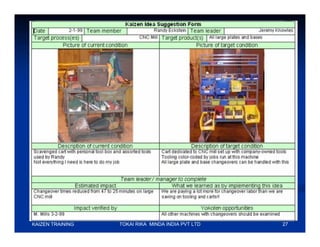

Kaizen is a system of continuous improvement in various aspects of a company. It was developed in 1950s Japan based on the Deming Cycle/PDSA cycle. The document discusses the introduction of Kaizen, 7 types of wastes, benefits of Kaizen culture, Toyota Production System, and how to implement a process of continuous improvement through small, incremental changes. The goal of Kaizen is to eliminate waste and improve productivity, quality and customer satisfaction through engaged employees continuously proposing improvements.