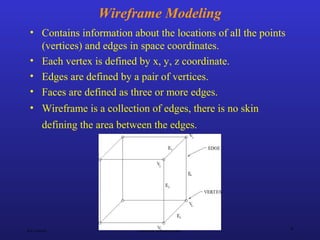

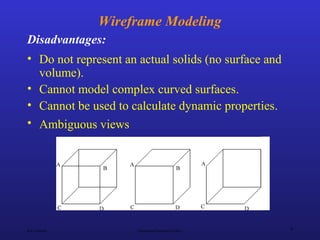

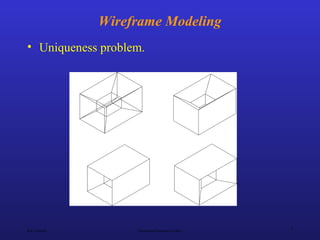

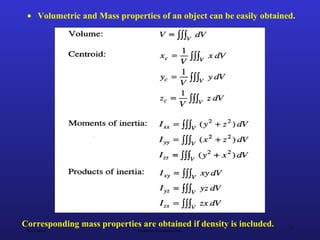

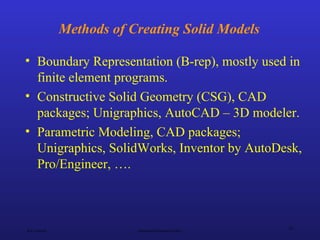

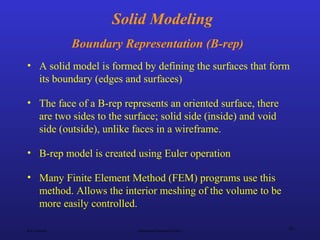

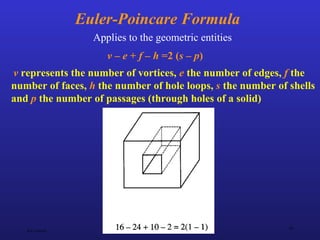

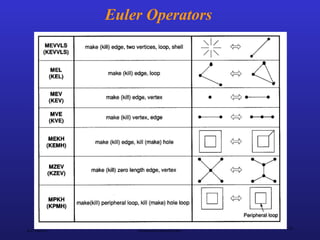

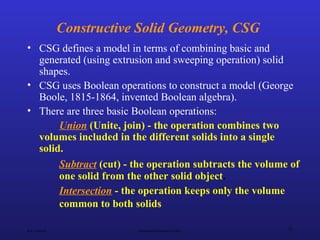

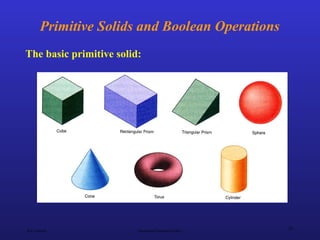

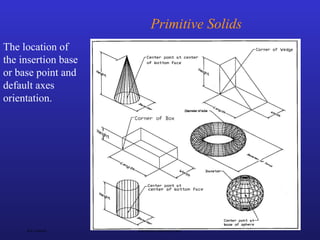

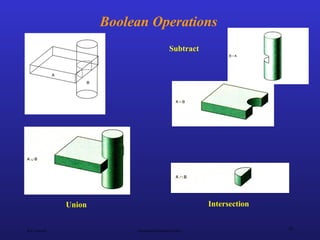

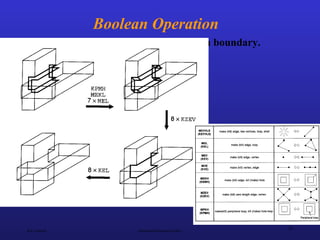

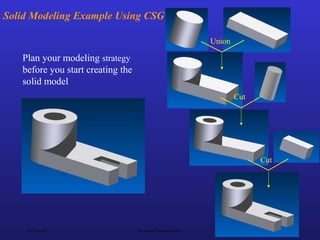

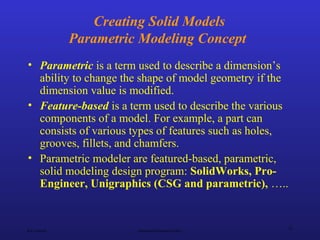

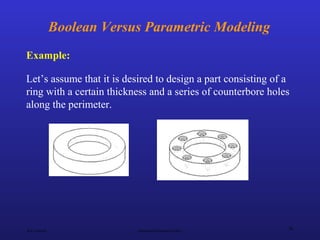

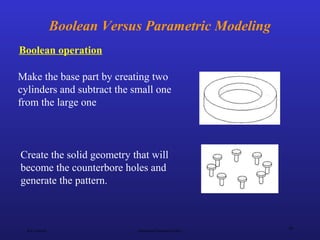

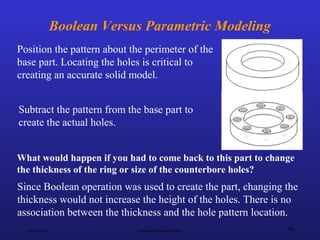

This document discusses different methods of 3D modeling, including wireframe modeling, surface modeling, and solid modeling. It provides details on each modeling method, including their advantages and disadvantages. For example, wireframe modeling only contains edge information and cannot represent actual solids, while solid modeling defines enclosed volumes and allows simulation under real-life conditions. The document also covers specific solid modeling techniques like boundary representation and constructive solid geometry, as well as parametric modeling concepts.