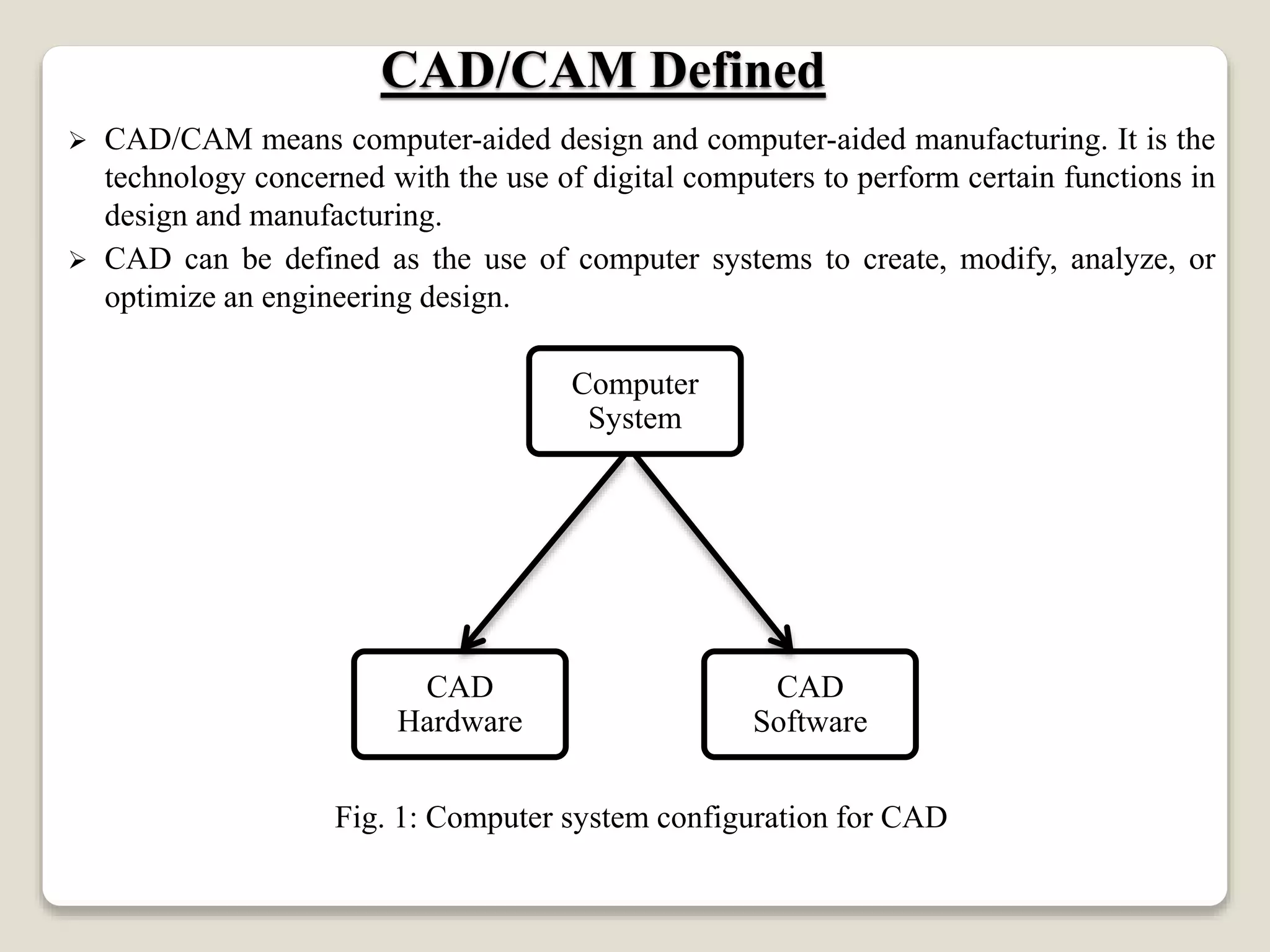

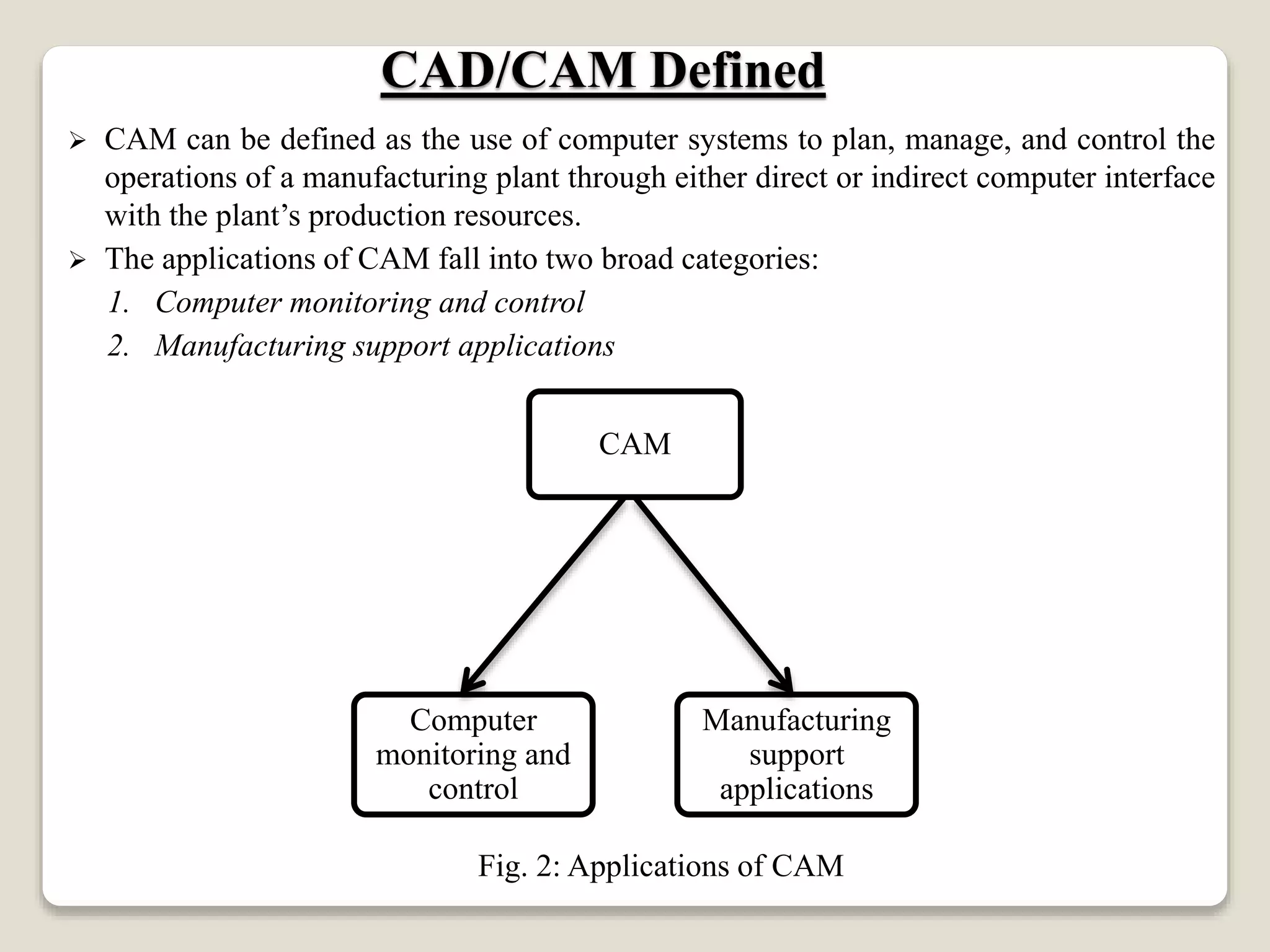

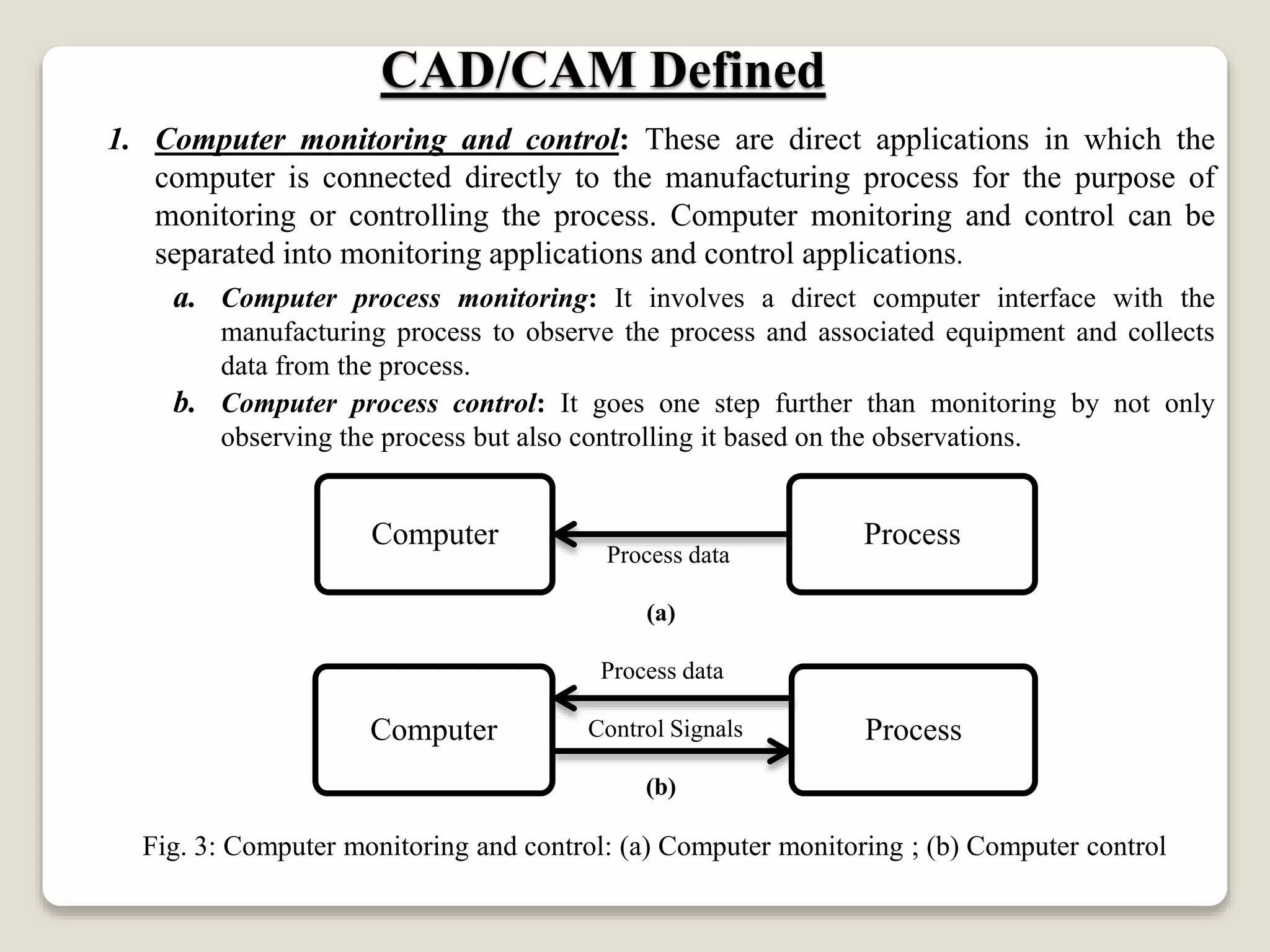

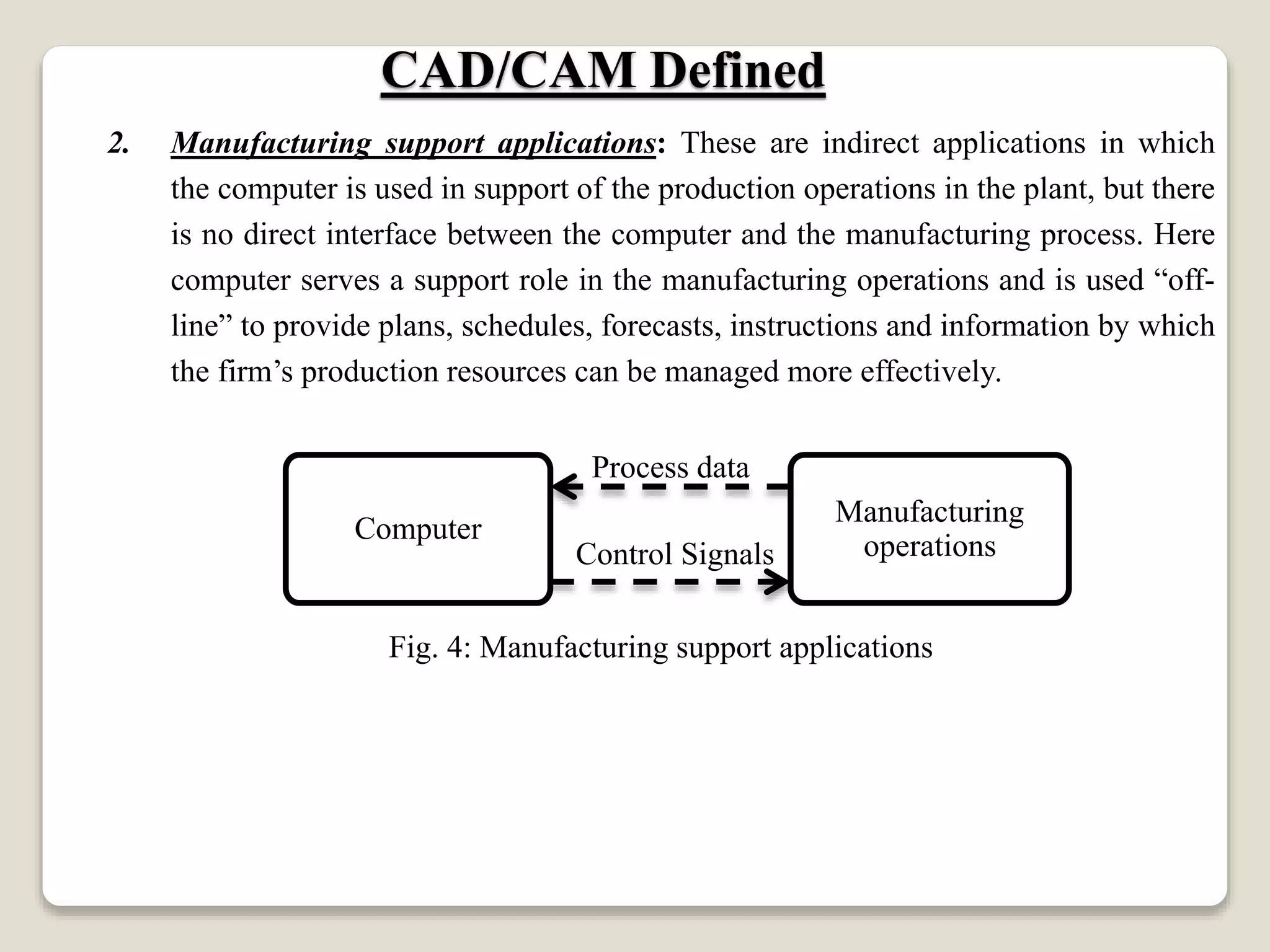

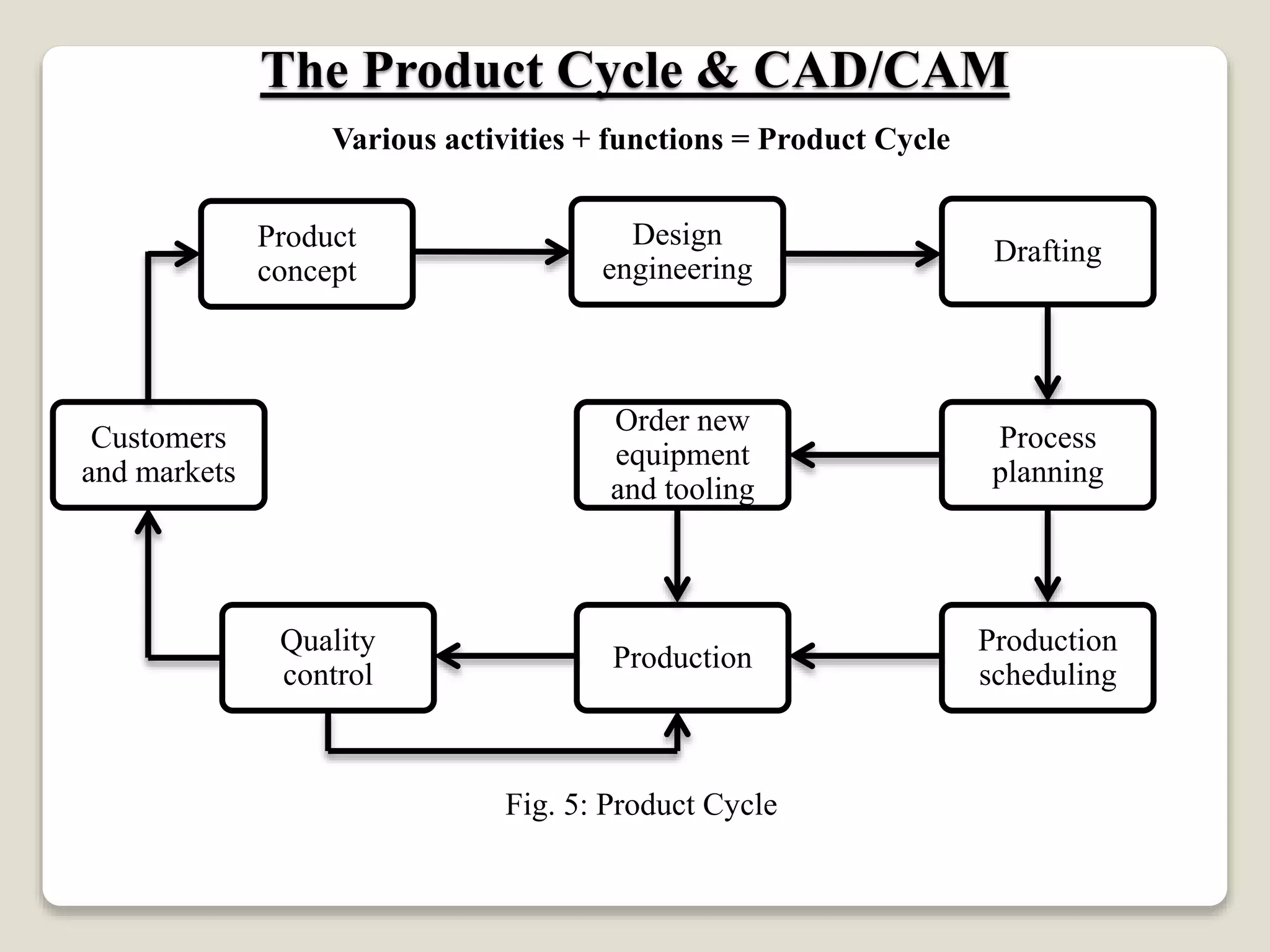

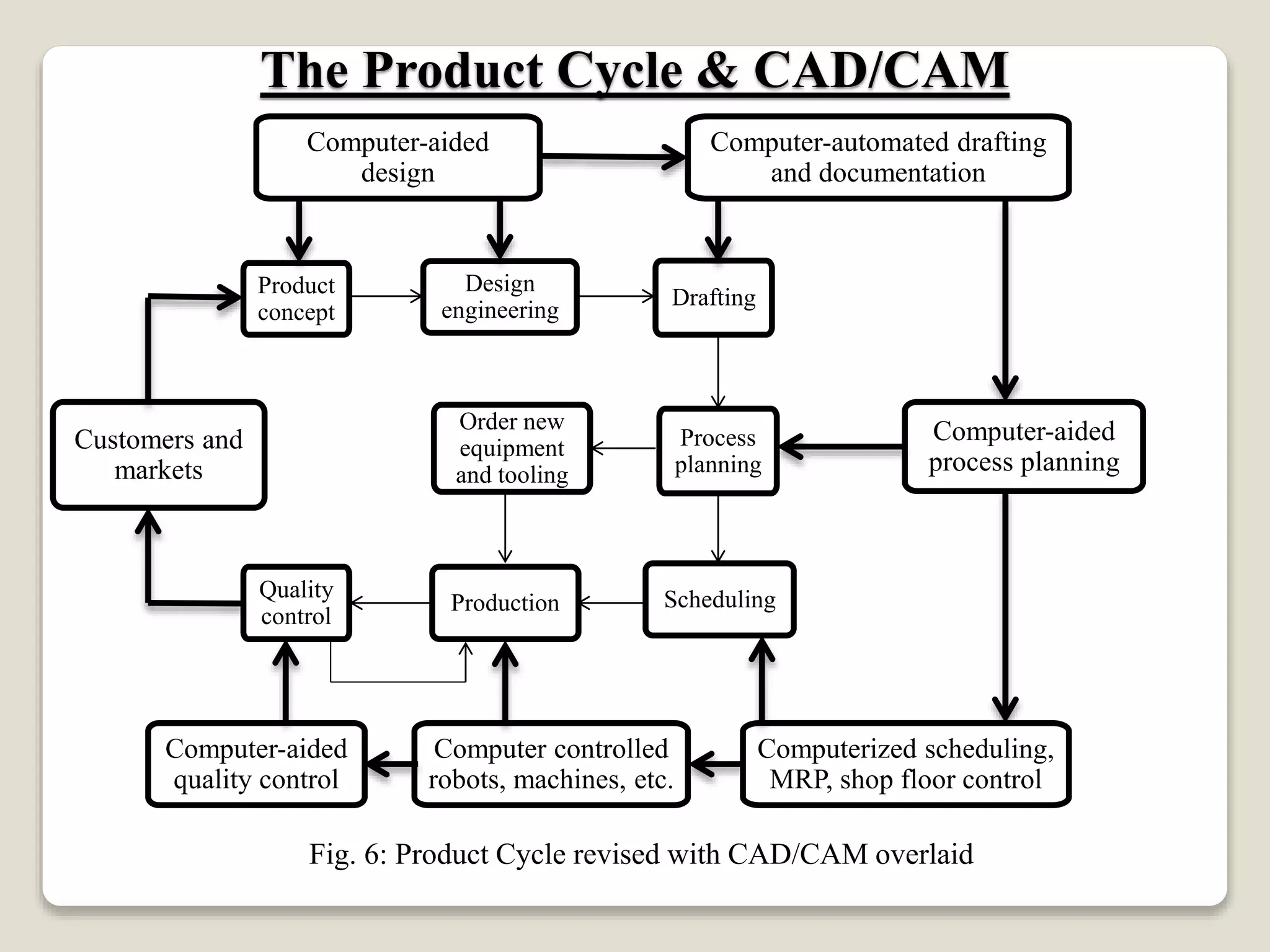

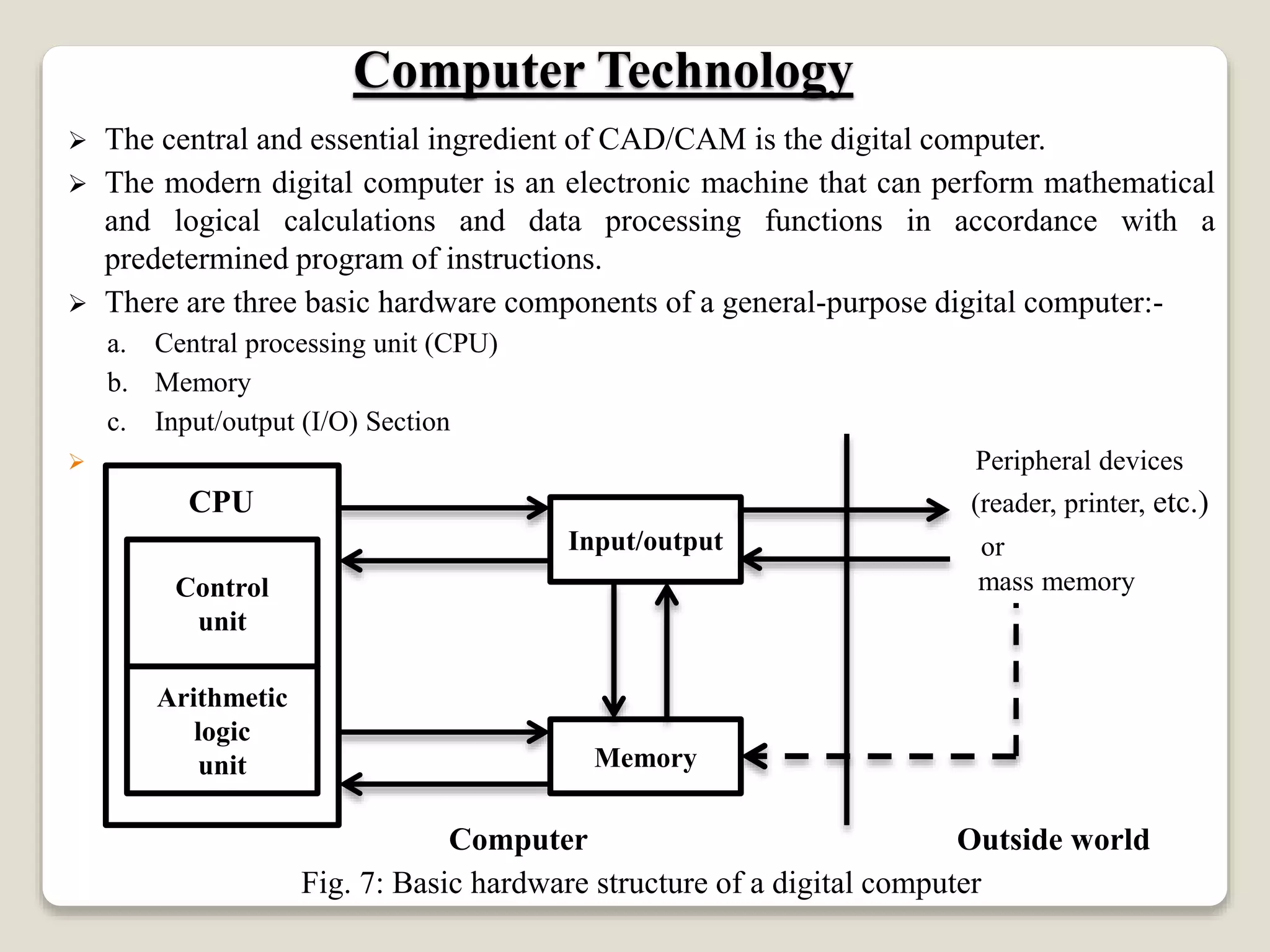

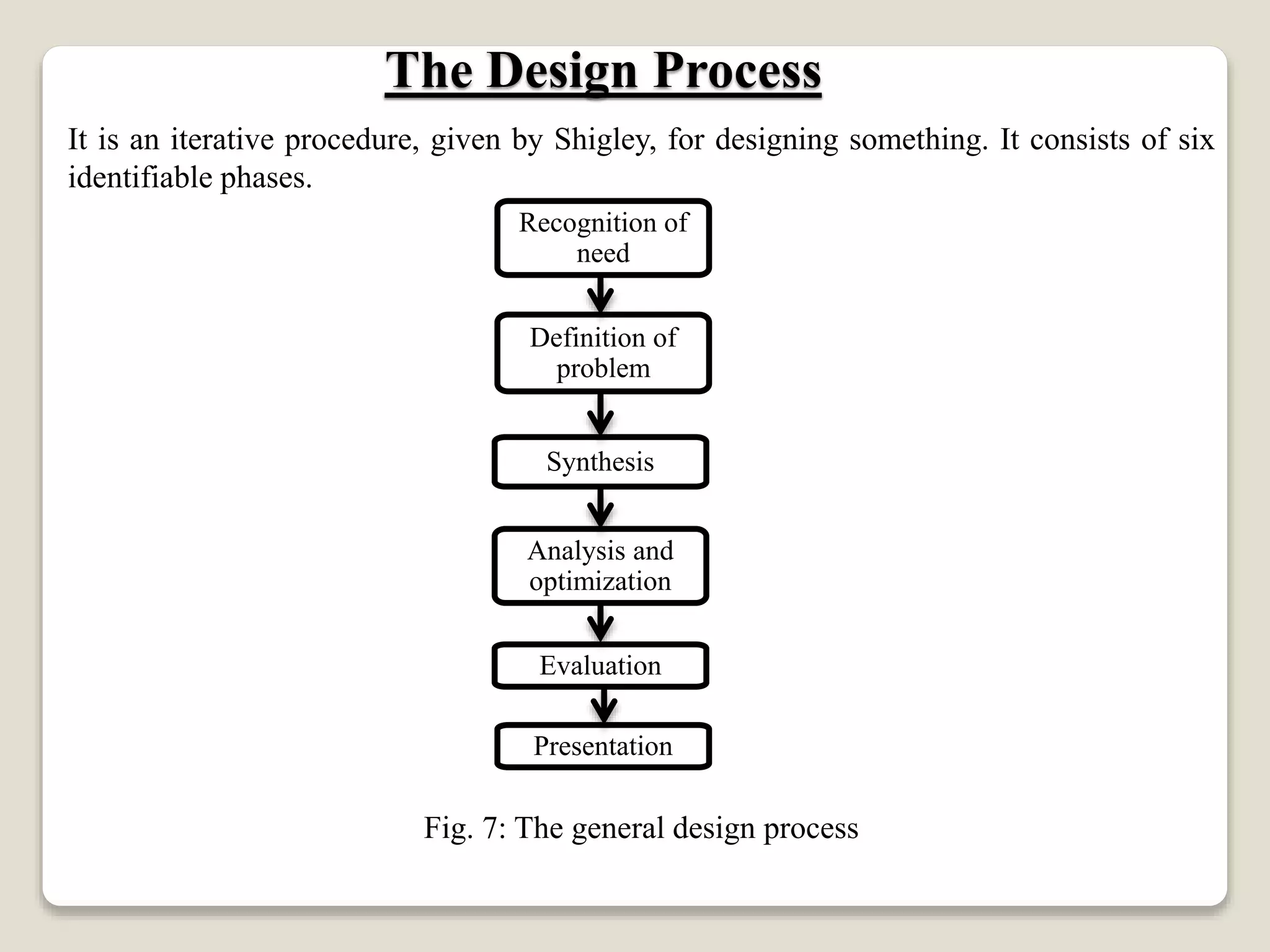

This document provides an introduction to computer-aided design (CAD). It defines CAD and computer-aided manufacturing (CAM) as using computers to aid in design and manufacturing functions. The document outlines the basic product design cycle and how CAD/CAM can be integrated at various stages, including computer-aided drafting, process planning, and computer-controlled manufacturing. It also describes the basic hardware and software components of CAD systems, including how interactive computer graphics are used to aid designers. Finally, it summarizes the general six-phase design process.