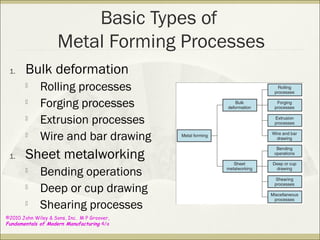

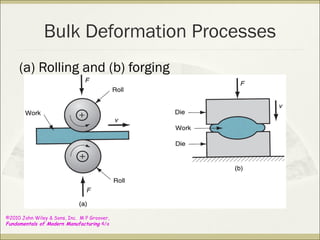

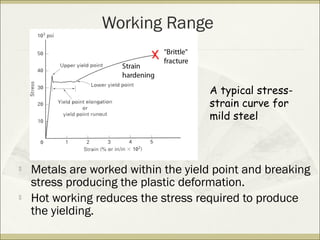

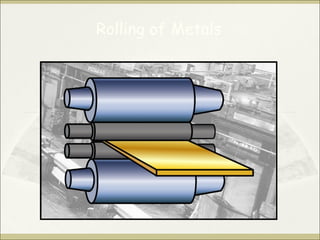

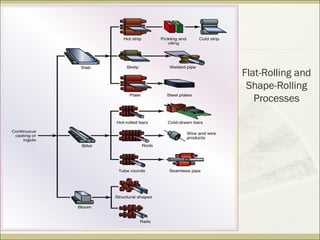

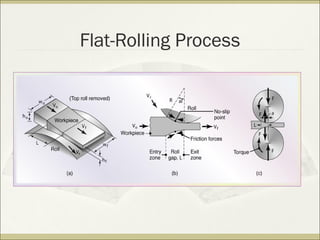

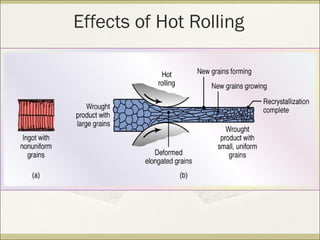

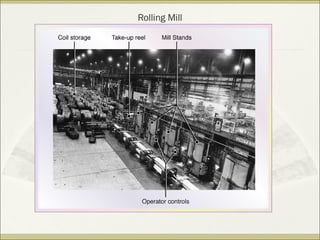

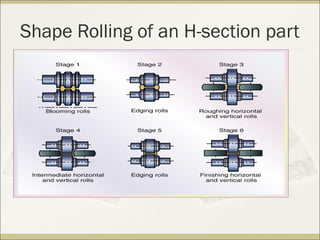

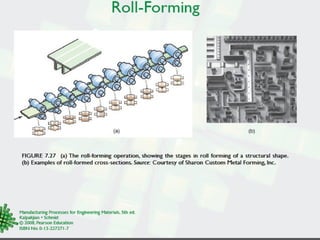

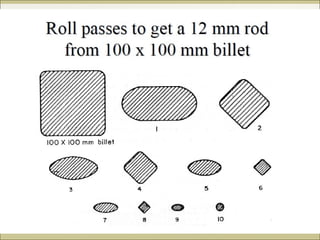

Metal forming processes use plastic deformation to change the shape of metal workpieces. Rolling is one of the most common metal forming processes, accounting for around 90% of metal shaping. In rolling, the metal workpiece is passed through one or more sets of rolls, reducing the thickness and changing the cross-sectional area under compressive forces applied by the rolls. The geometry of the final product is determined by the shape and contour of the roll gap. Rolling can be performed hot or cold, and is used to produce a wide variety of parts for structural applications and transportation.