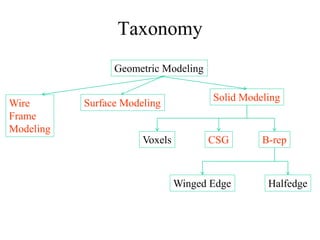

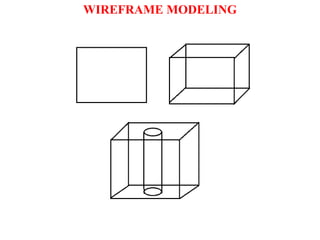

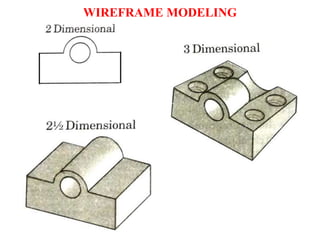

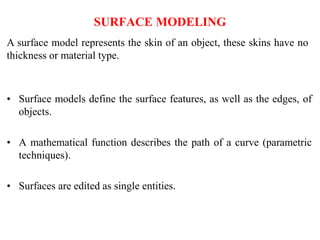

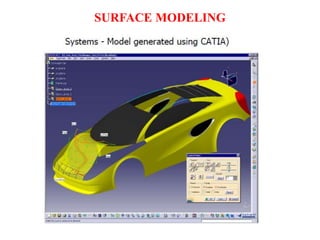

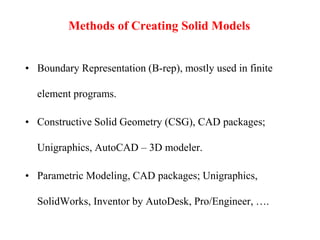

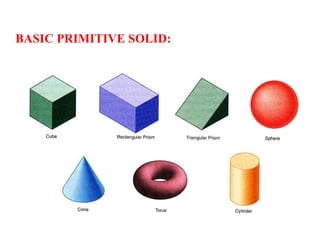

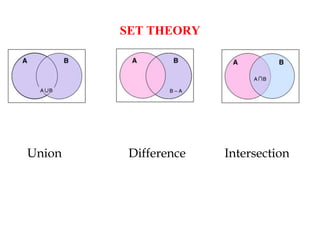

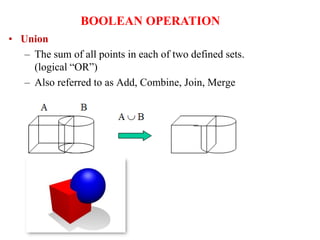

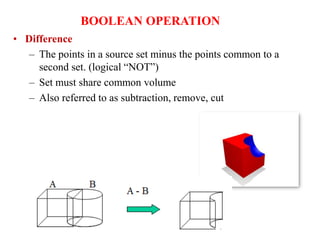

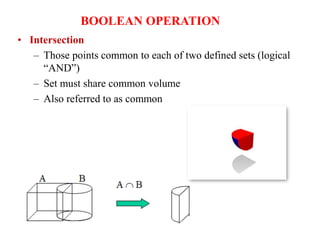

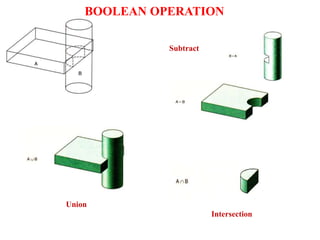

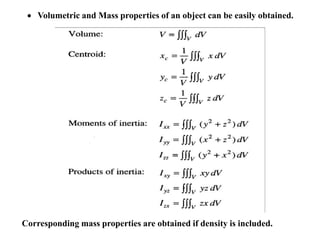

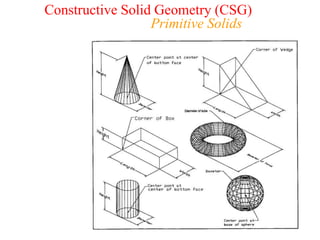

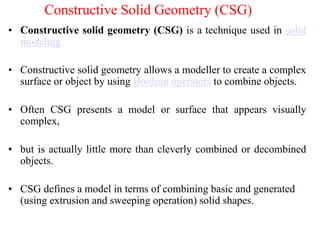

Geometric modeling involves creating mathematical representations of geometric objects using CAD software. There are three main types of geometric models: wireframe models using lines and curves, surface models representing an object's surface, and solid models representing the complete volumetric shape. Solid modeling is now the most common approach as it allows for properties like mass to be calculated and enables applications like finite element analysis. Geometric models can be created using set operations in constructive solid geometry or parametric modeling techniques.