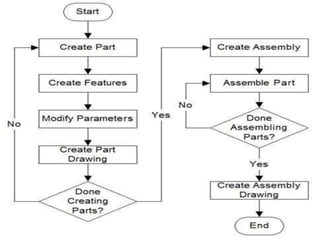

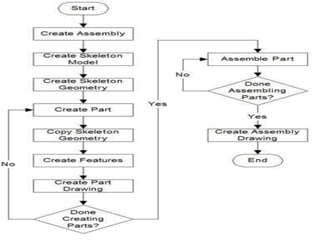

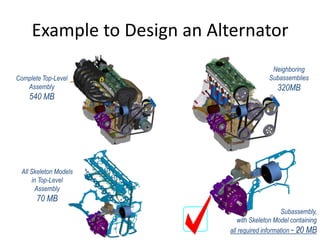

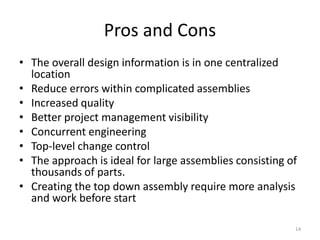

Top down assembly modeling involves first creating an assembly file with a skeleton layout sketch. Parts are then created within the assembly file and assembled using constraints. This approach allows designing from the overall assembly down to individual components. Benefits include having all design information centralized, reducing errors, and better managing large assemblies with thousands of parts. However, more upfront analysis is required compared to the bottom up approach of first creating individual parts separately before assembling them.