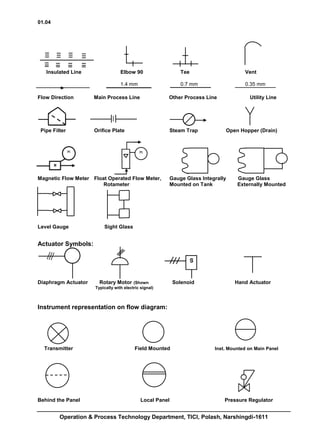

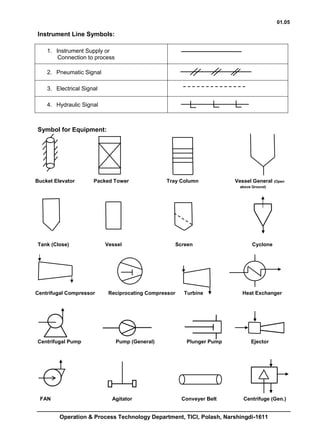

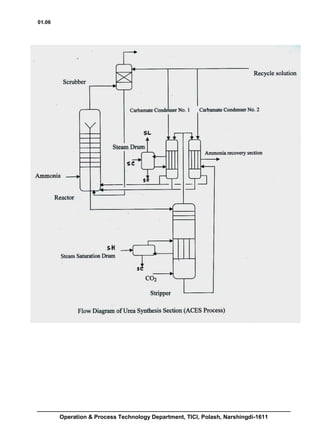

This document discusses process symbols and diagrams used in industrial processes. It defines symbols as graphical representations used to create diagrams of plants and processes. It then discusses different types of common diagrams - block diagrams, flow diagrams, process flow diagrams, and piping and instrumentation diagrams. For each diagram type, it provides details on what they represent and what information they typically include. It also discusses standard symbol sets adopted by international organizations and provides examples of specific symbols for equipment, instruments, valves, and other process elements.