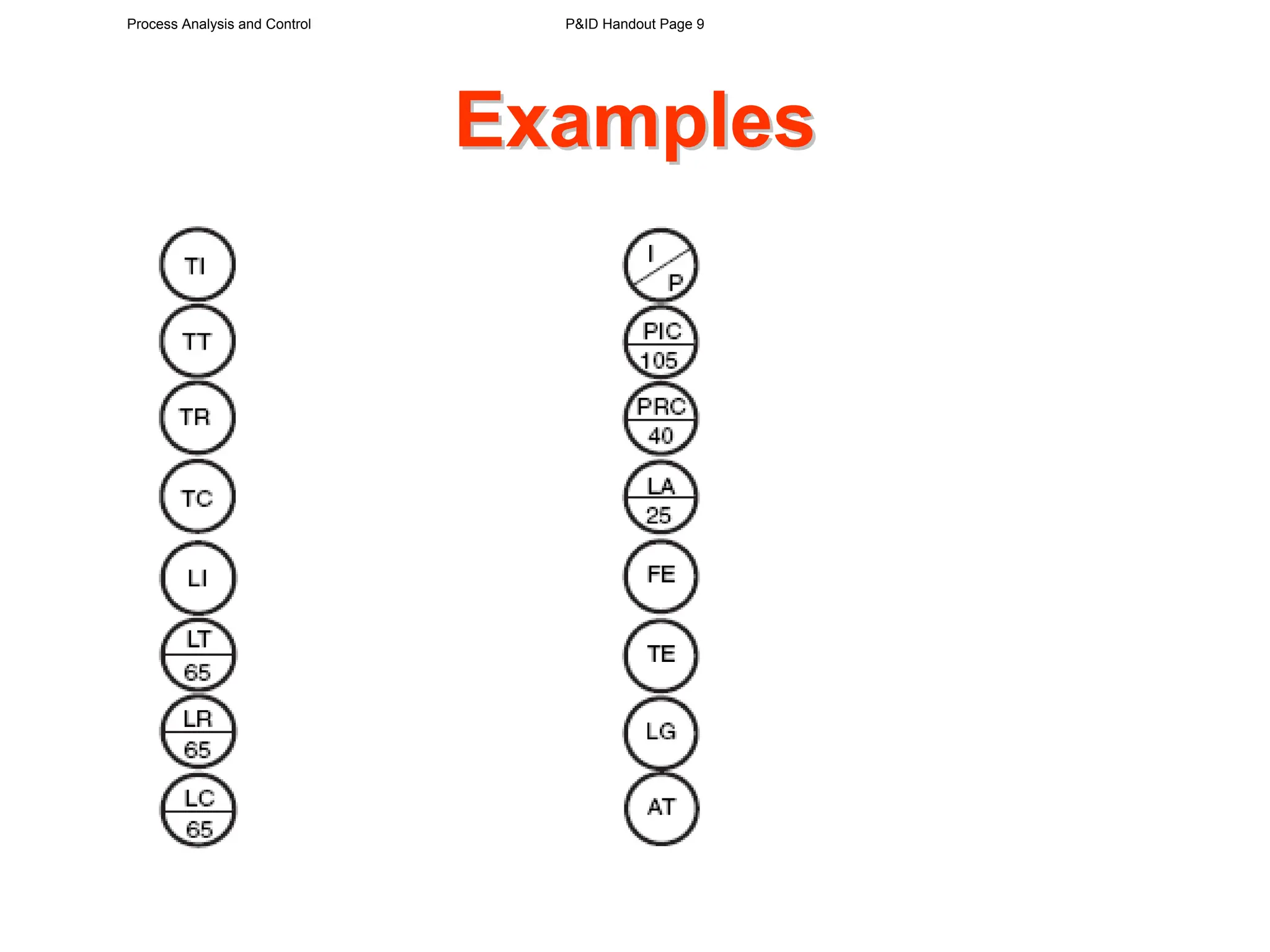

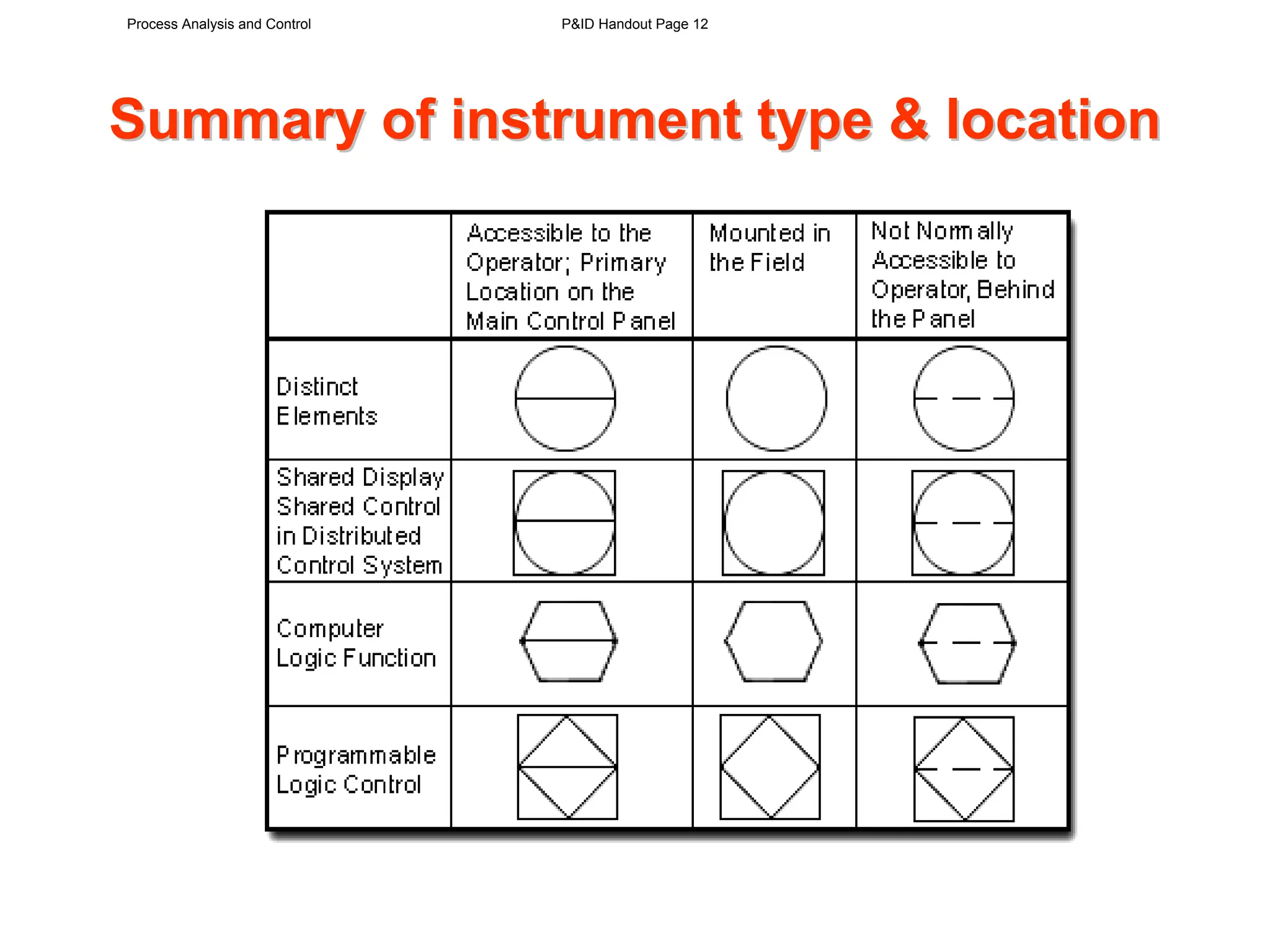

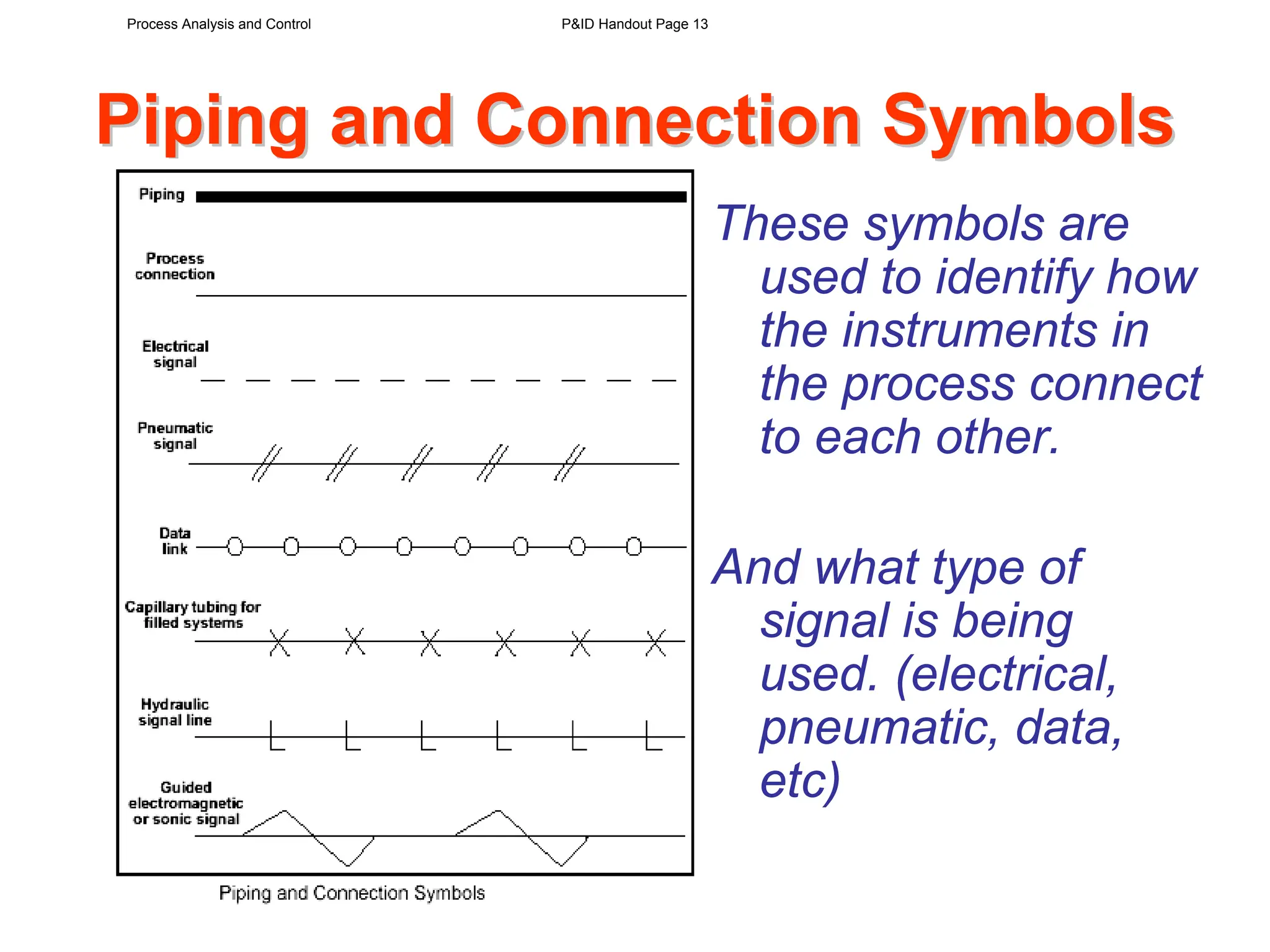

The document provides an overview of Piping and Instrumentation Diagrams (P&IDs), which are standardized schematics used in instrumentation and control. It explains the symbols, tag numbers, instrument locations, and types used to represent instruments and their connections within a process. Additionally, it discusses the difference between P&IDs and Process Flow Diagrams (PFDs), highlighting their respective purposes in process analysis.