The document provides an overview of industrial hydraulics, including:

- The definition and etymology of hydraulics.

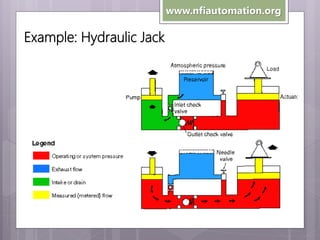

- Examples of hydraulics in everyday life and basic hydraulic systems like hydraulic jacks.

- Key figures in the development of hydraulics like Joseph Bramah.

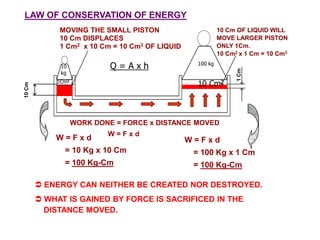

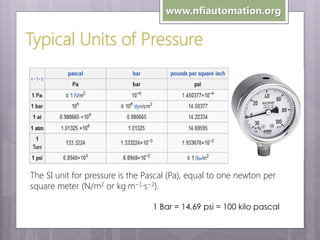

- Fundamental hydraulic principles like Pascal's law.

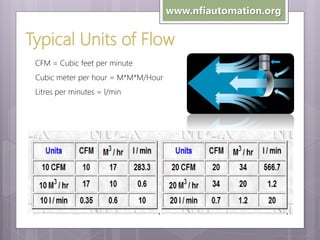

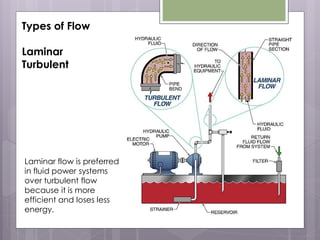

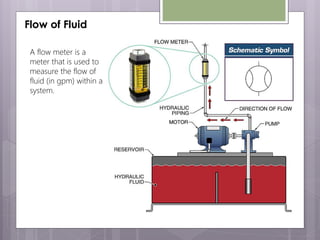

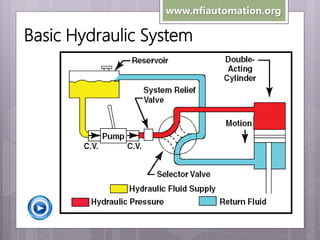

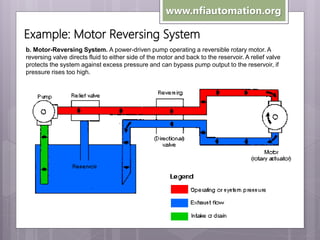

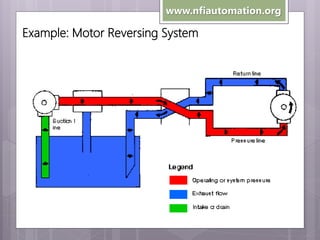

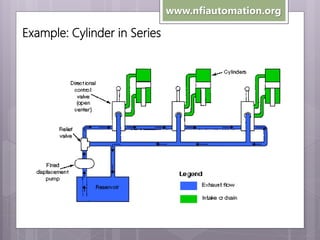

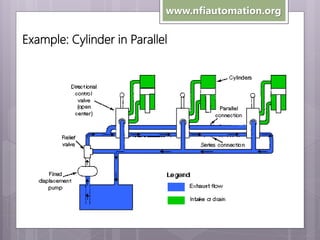

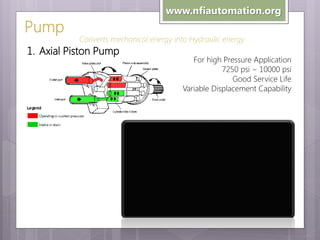

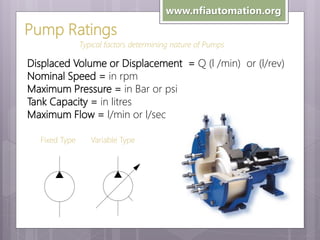

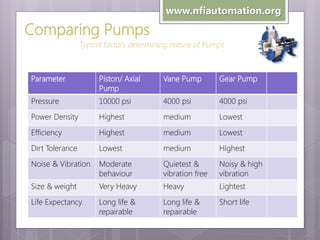

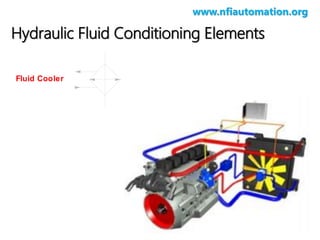

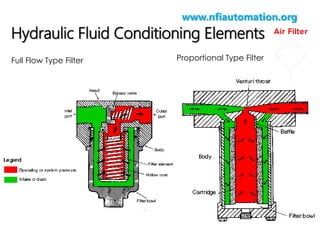

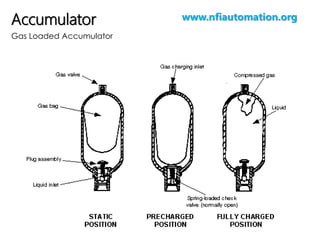

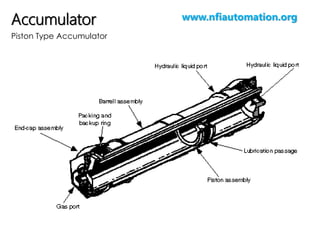

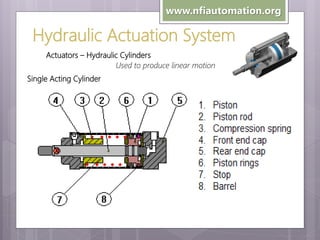

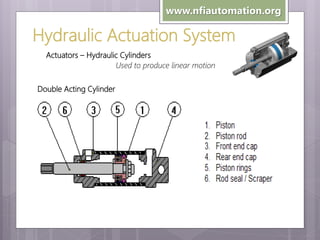

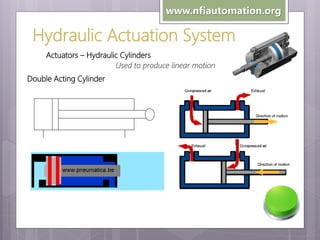

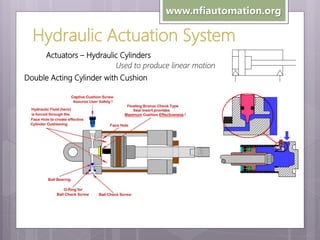

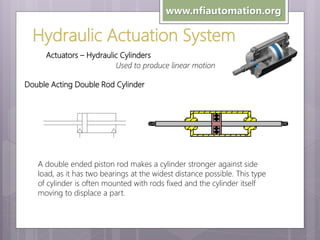

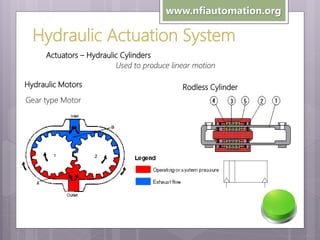

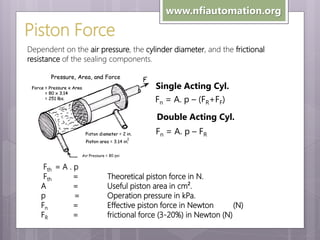

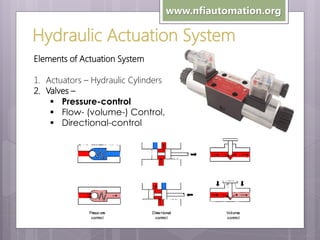

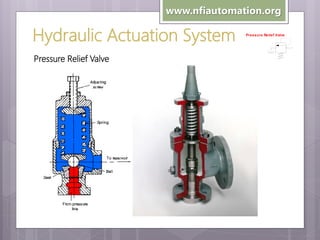

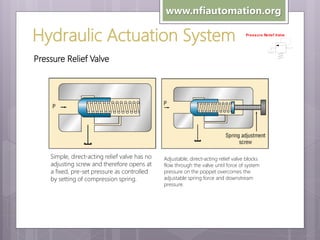

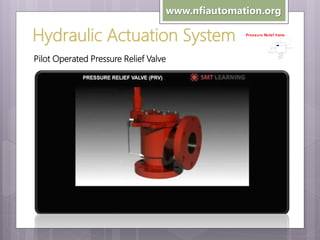

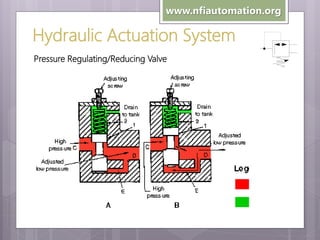

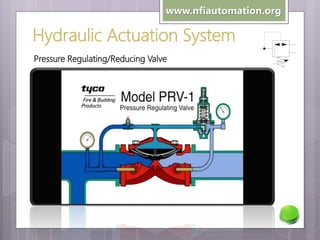

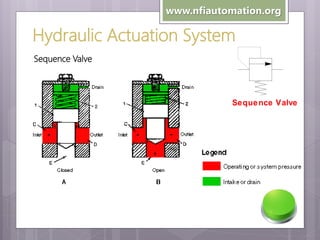

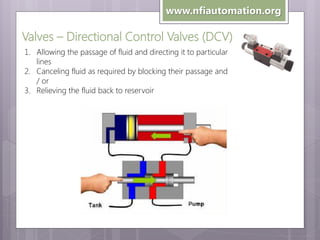

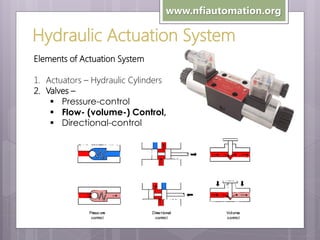

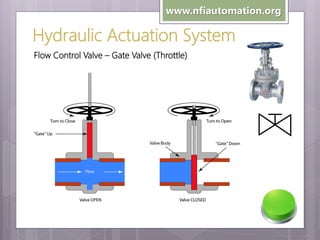

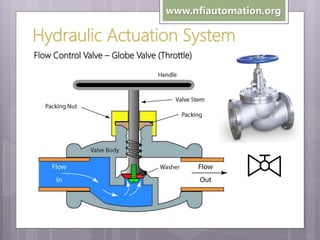

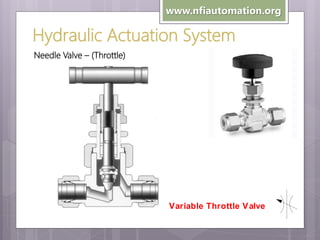

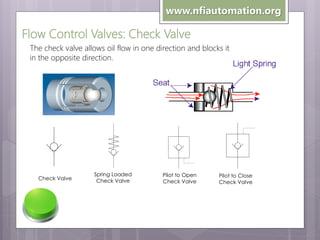

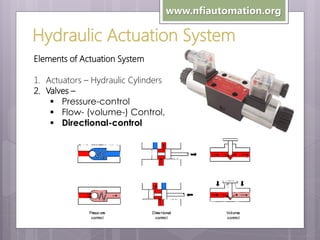

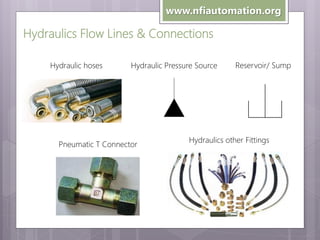

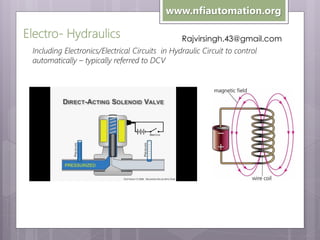

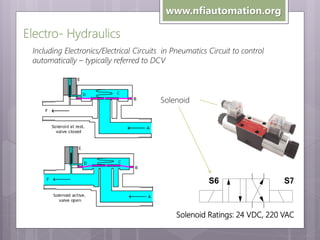

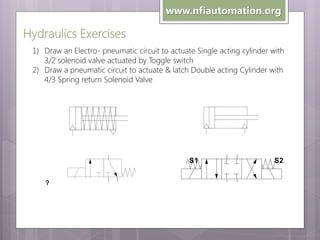

- Components of hydraulic systems like pumps, valves, actuators, and fluid conditioning elements.

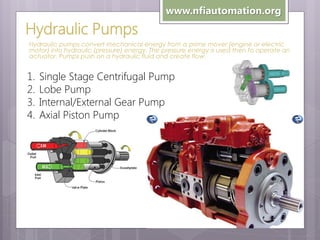

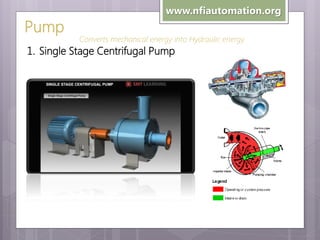

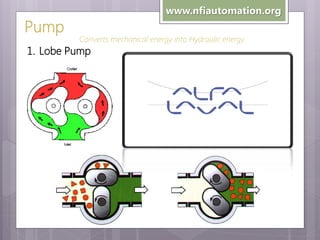

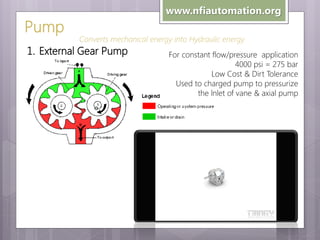

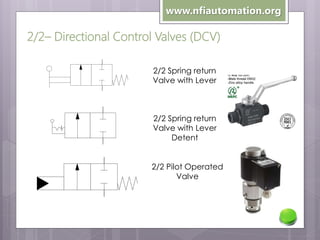

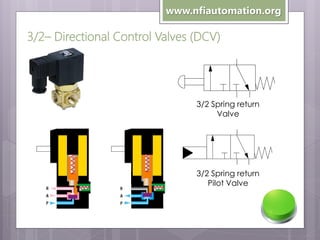

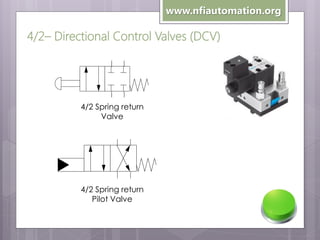

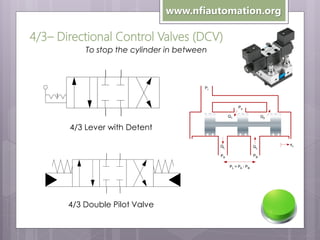

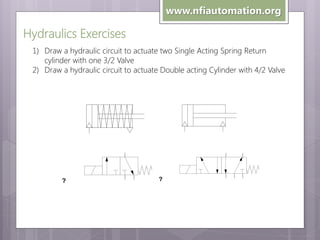

- Types of hydraulic pumps, cylinders, motors, and directional control valves.