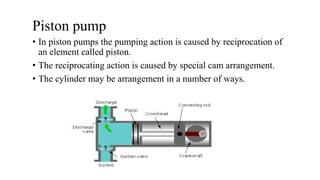

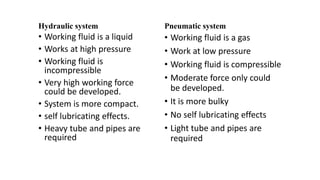

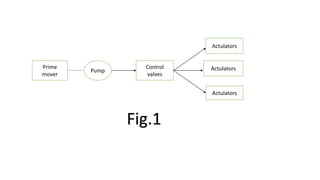

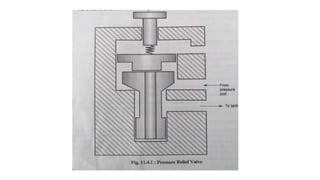

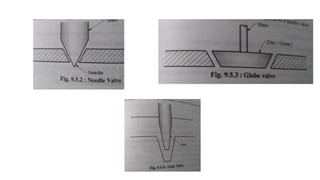

This presentation provides an overview of hydraulic control systems. It discusses the basic components including pumps, control valves, actuators, and piping. It describes the functions of various pressure control valves, flow control valves, and directional control valves. It also discusses hydraulic power sources like pumps and actuators like cylinders. In summary, the presentation introduces hydraulic control systems, outlines their major components, and describes the purpose and classification of key valves and actuators used in these systems.

![Classsification of [dcvs]

•Three way two positon

•Four way two position

•Four way three position](https://image.slidesharecdn.com/ce-191015133557/85/Ce-pptx-2-23-320.jpg)