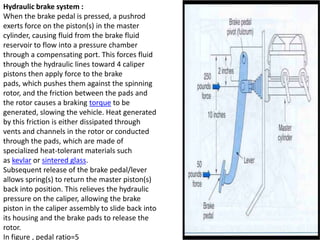

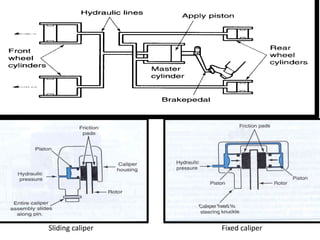

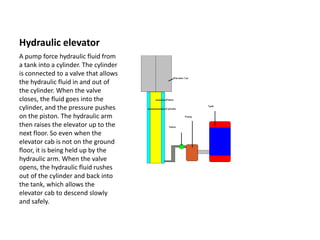

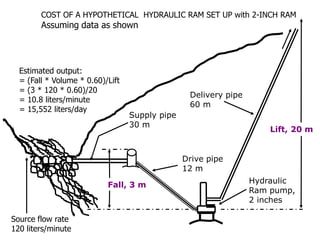

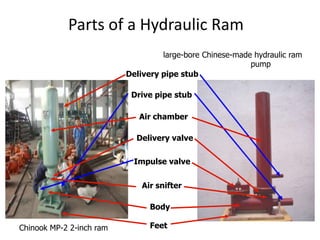

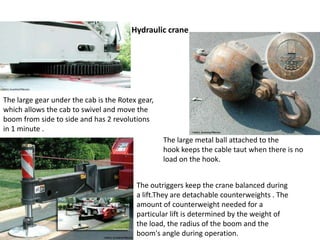

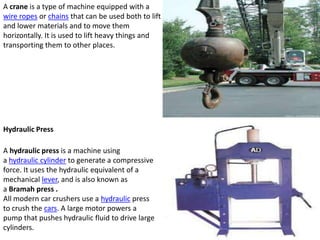

This document provides an overview of applications of fluid hydraulics including: hydraulic brake systems which use fluid pressure to slow vehicles; hydraulic elevators which use fluid pressure to raise elevator cars; hydraulic shock absorbers which absorb energy using fluid flow through pistons; hydraulic rams which use falling water to power fluid flow and lift water; hydraulic cranes which use fluid pressure to lift heavy loads; and hydraulic presses which use fluid pressure in cylinders to compress materials. The document also discusses advantages of hydraulics including high power and safety, and disadvantages such as potential leaks and temperature sensitivity.

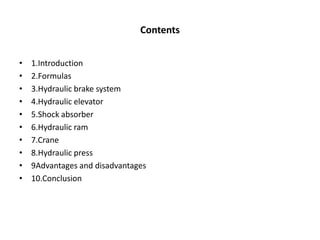

![Introduction

Hydraulics is used for the generation, control, and transmission of fluids in

order to produce some mechanical work .

Formulas :

• Hydraulic power is defined as flow times pressure. The hydraulic power

supplied by a pump : Power = (P x Q) ÷ 600where power is in kilowatts

[kW], P pressure in bars, and Q is the flow in liters per minute.

• For example, a pump delivers 180 lit/min and the pressure equals 250

bar, therefore the power of the pump is 75 kW.

• Power input = Power output ÷ ηtotal. For example,the average for axial

piston pumps, ηtotal = 0.87 , the diesel engine or an electric motor, must

be capable of delivering at least 75 ÷ 0.87 = 86 kW.

• ηtotal = ηvol ηhm.

• ηvol =volumetric efficiency , ηhm=hydromechanical efficiency .](https://image.slidesharecdn.com/applicationsoffluidhydraulics-131008093919-phpapp02/85/Applications-of-fluid-hydraulics-4-320.jpg)