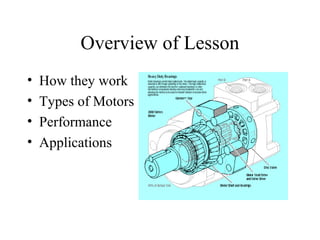

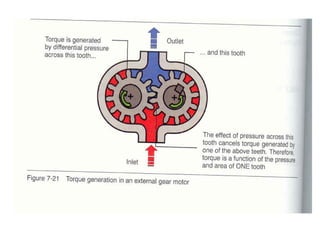

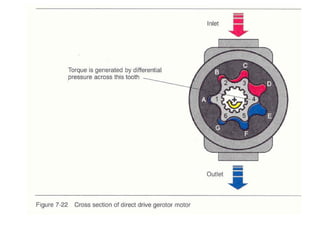

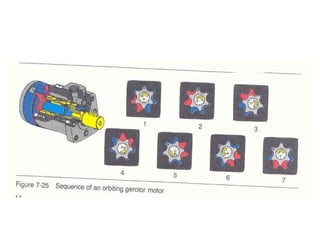

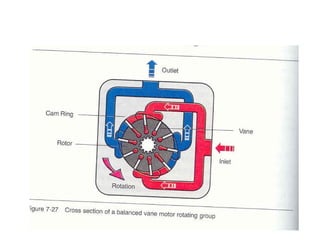

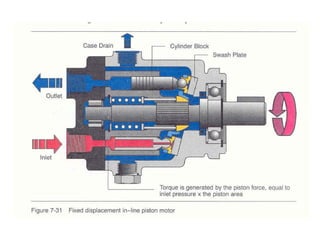

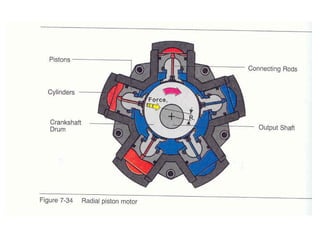

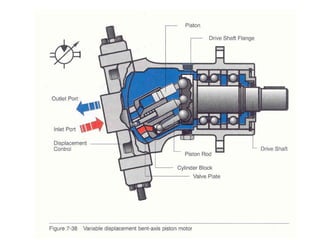

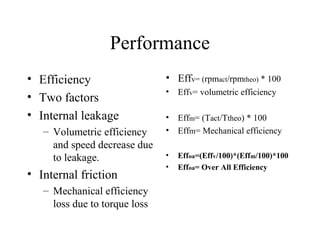

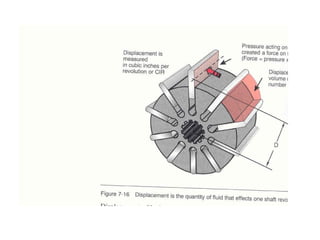

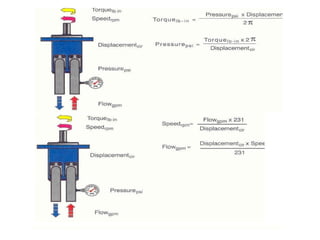

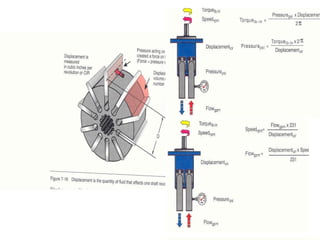

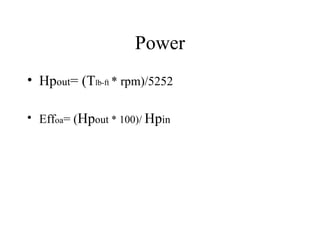

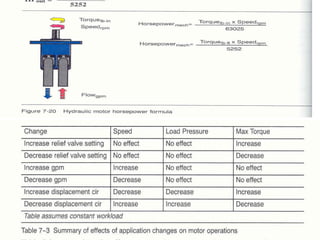

Hydraulic motors use high pressure fluid to turn a shaft. There are several types including gear motors, vane motors, and piston motors. Gear motors use rotating gears where fluid pressure creates force. Piston motors are often the most efficient and used in aerospace due to their high power to weight ratio. Performance is determined by efficiency factors like internal leakage and friction. Calculations can determine required pressure, flow rate, power output, and efficiency.