The document summarizes key concepts in hydraulics including:

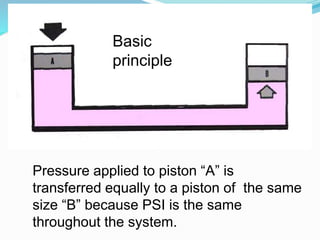

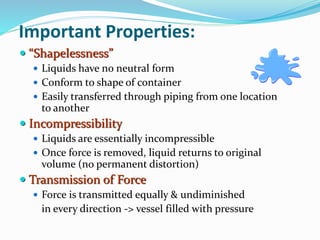

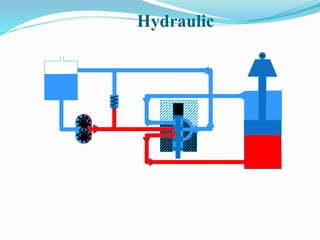

1. Hydraulics uses liquids to transmit force via Pascal's law, where pressure is transmitted undiminished throughout a confined liquid.

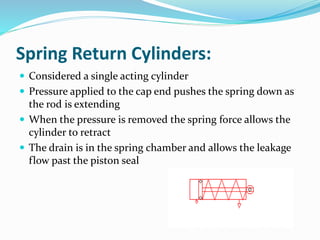

2. Key components include pumps to pressurize fluid, cylinders to convert hydraulic power into mechanical motion, and control valves to direct fluid flow.

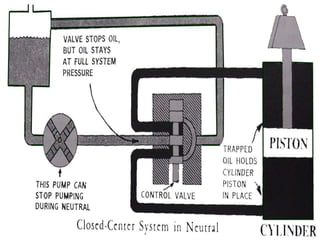

3. There are different types of hydraulic systems, pumps, cylinders and valves that are suited to various applications and pressure requirements.