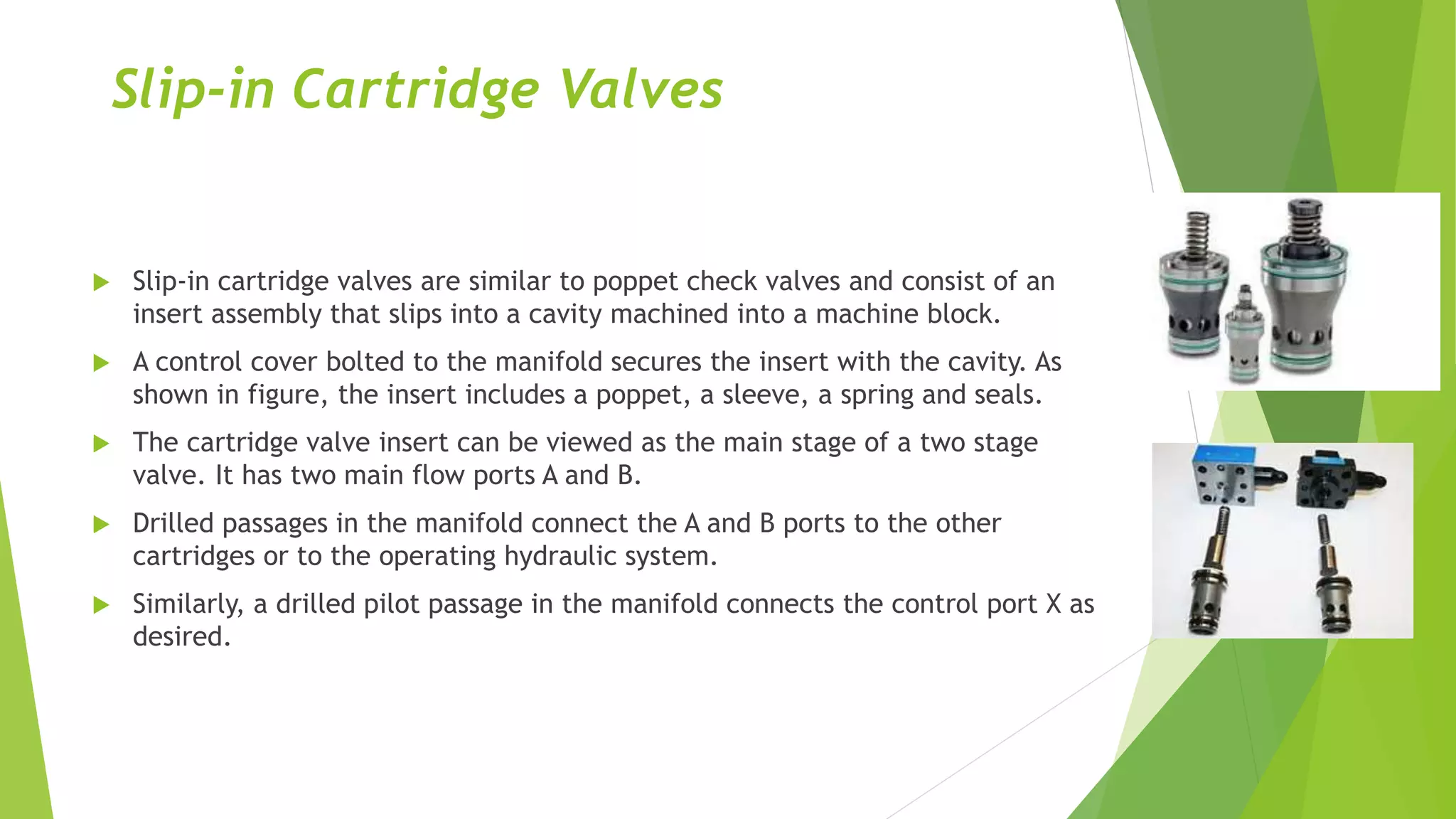

Servo valves and proportional valves are types of directional control valves that can precisely control the amount and direction of fluid flow to actuators. Mechanical servo valves use a mechanical linkage to position a valve spool, while electro-hydraulic servo valves use an electric current. Proportional valves can assume intermediate positions between fully open and closed through variation of an electric current controlling a solenoid. Cartridge valves offer design flexibility and performance advantages over conventional sliding spool valves by providing directional flow and pressure control through poppet-style inserts.