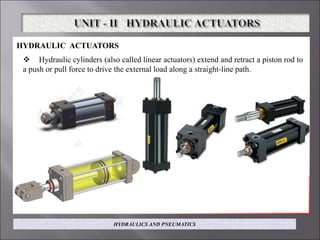

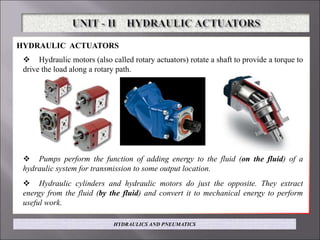

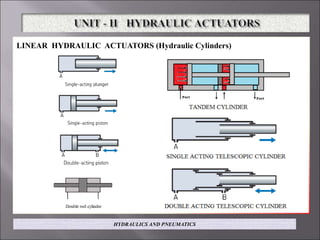

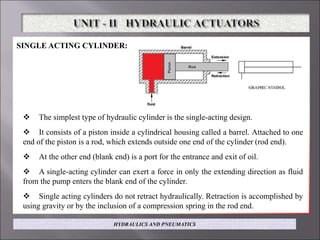

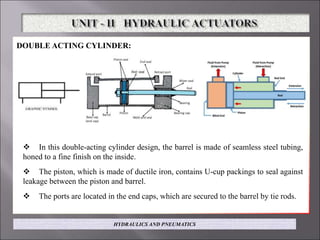

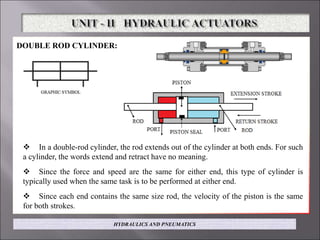

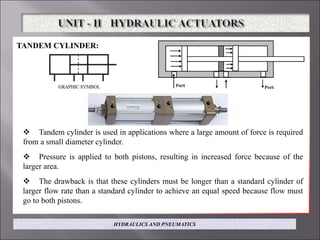

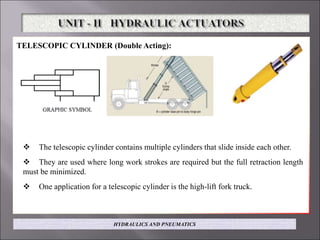

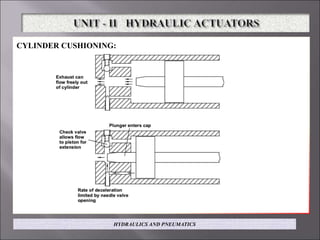

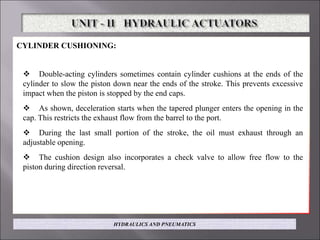

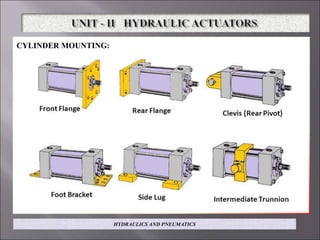

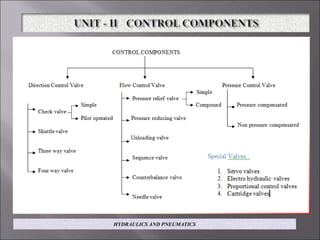

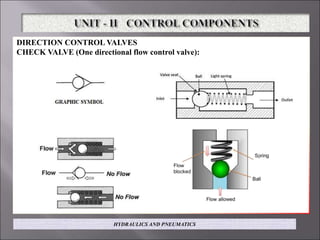

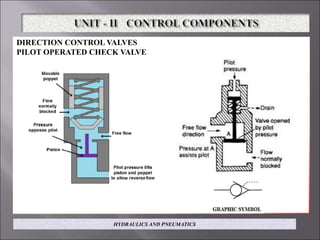

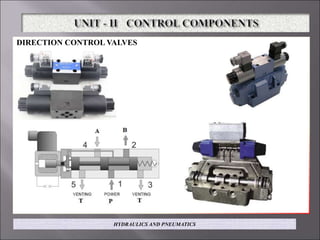

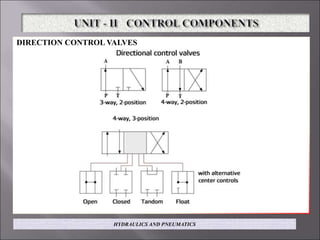

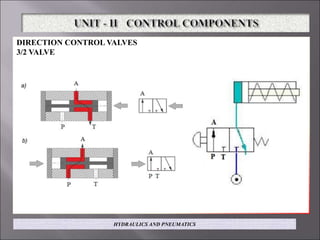

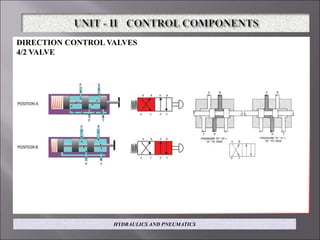

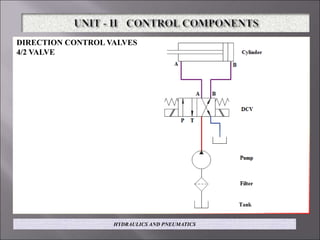

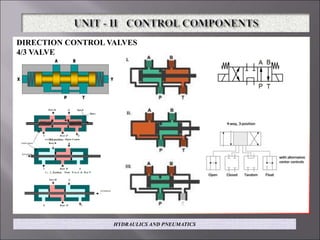

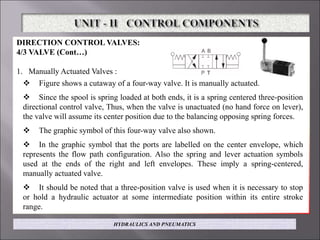

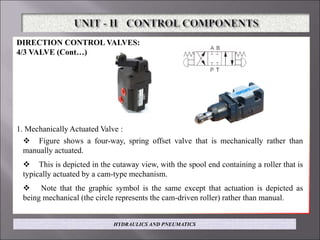

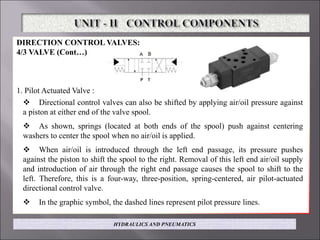

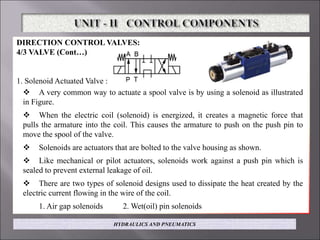

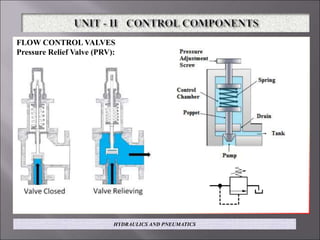

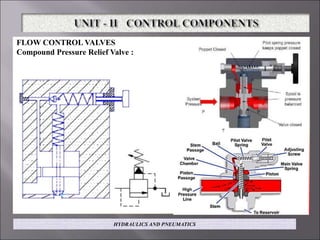

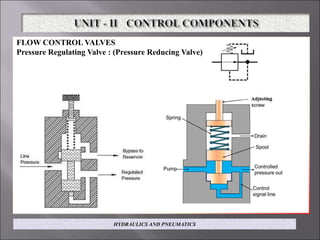

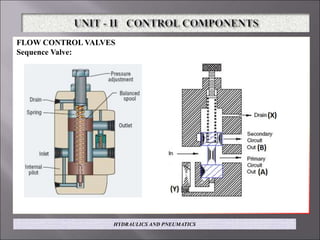

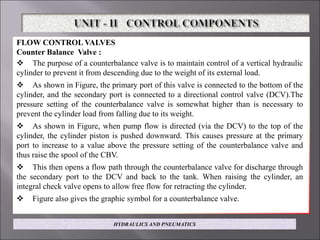

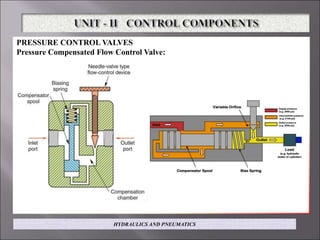

This document discusses various hydraulic actuators and control components. It begins by describing different types of hydraulic cylinders including single acting, double acting, double rod, tandem, and telescopic cylinders. It then discusses cylinder cushioning and mounting. The document next covers various directional control valves including check valves, pilot operated check valves, 3/2 valves, 4/2 valves, and 4/3 valves. It provides details on the construction and operation of each. Finally, the document discusses flow control valves including pressure relief valves and compound pressure relief valves.