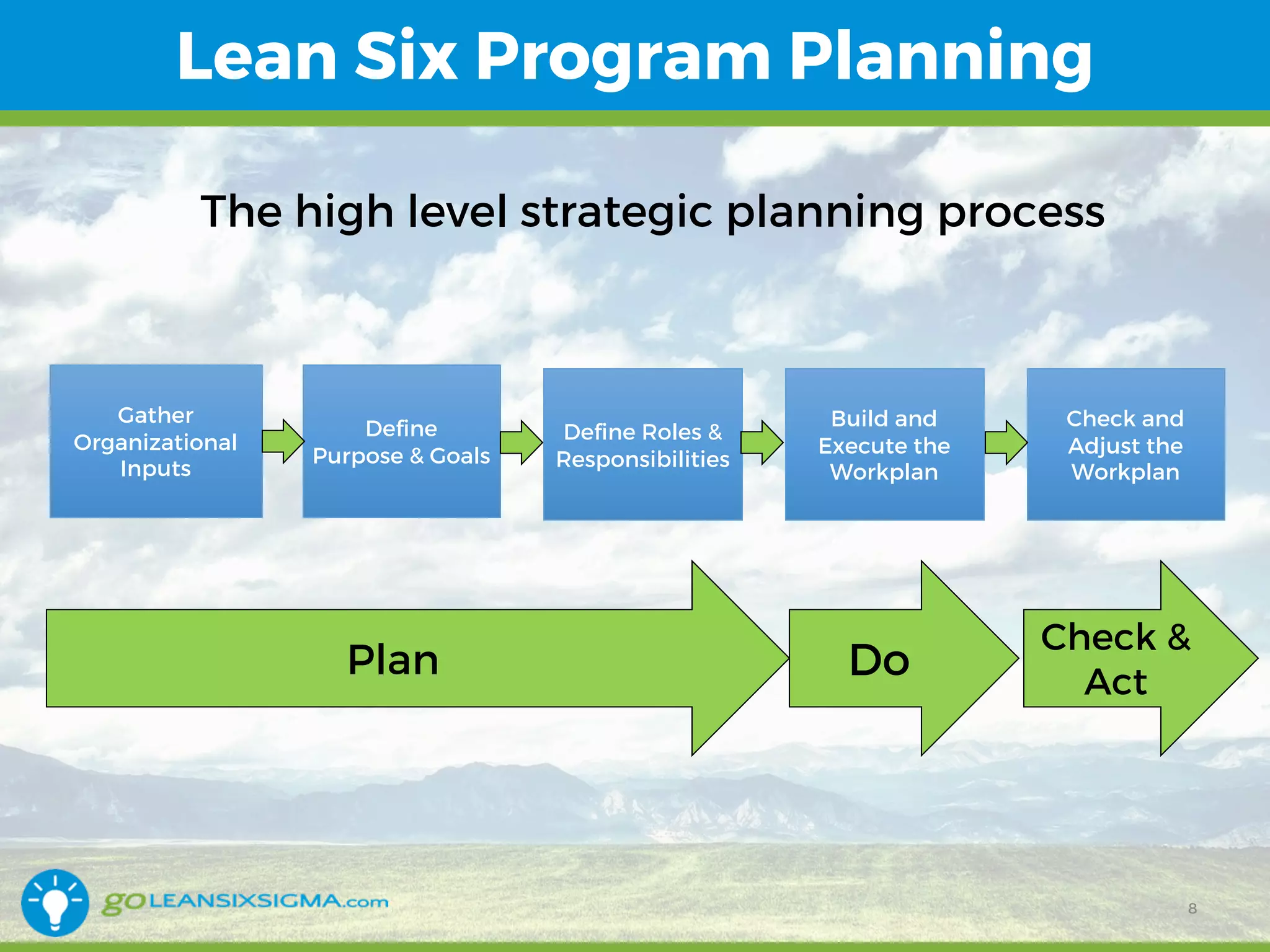

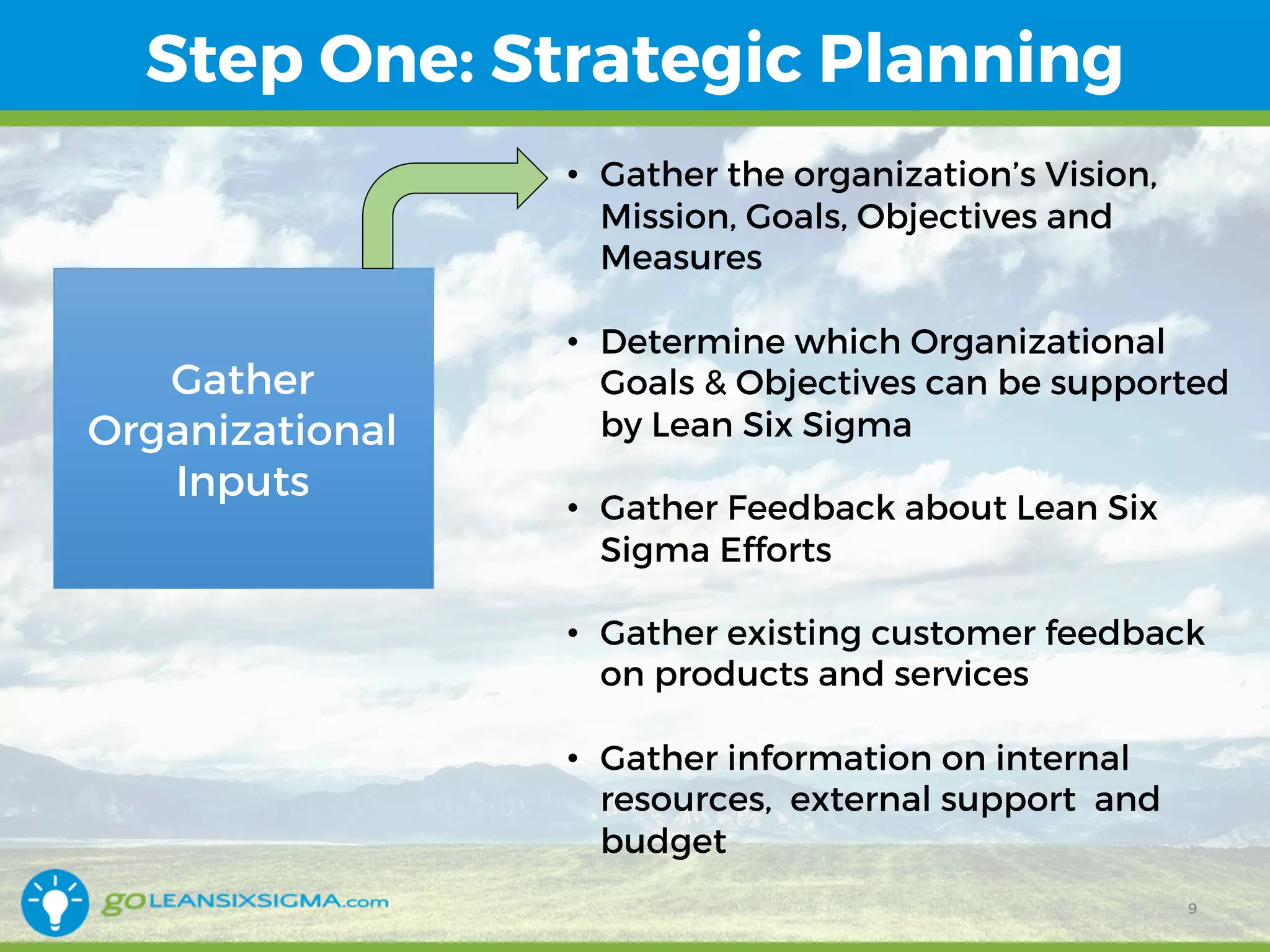

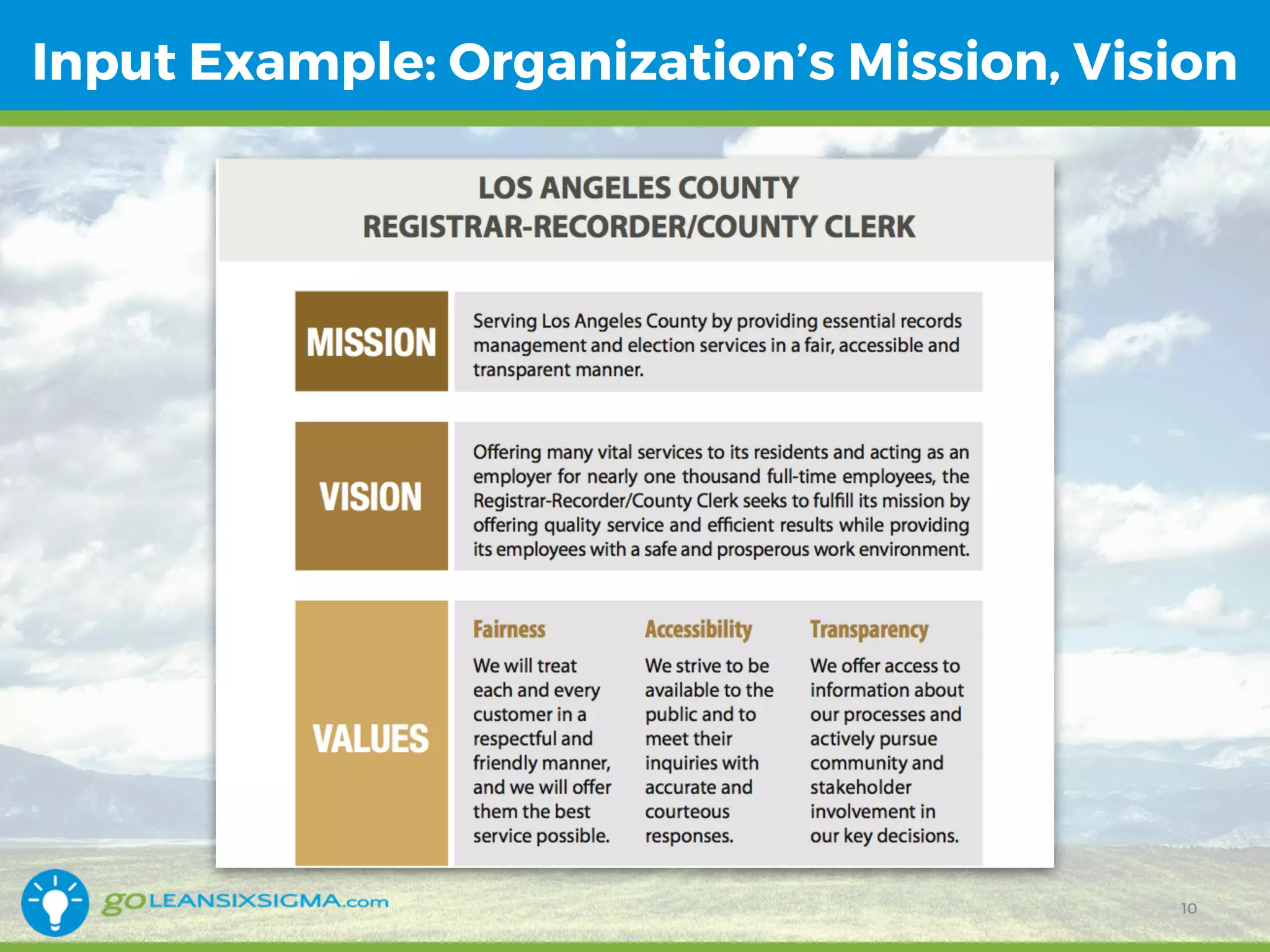

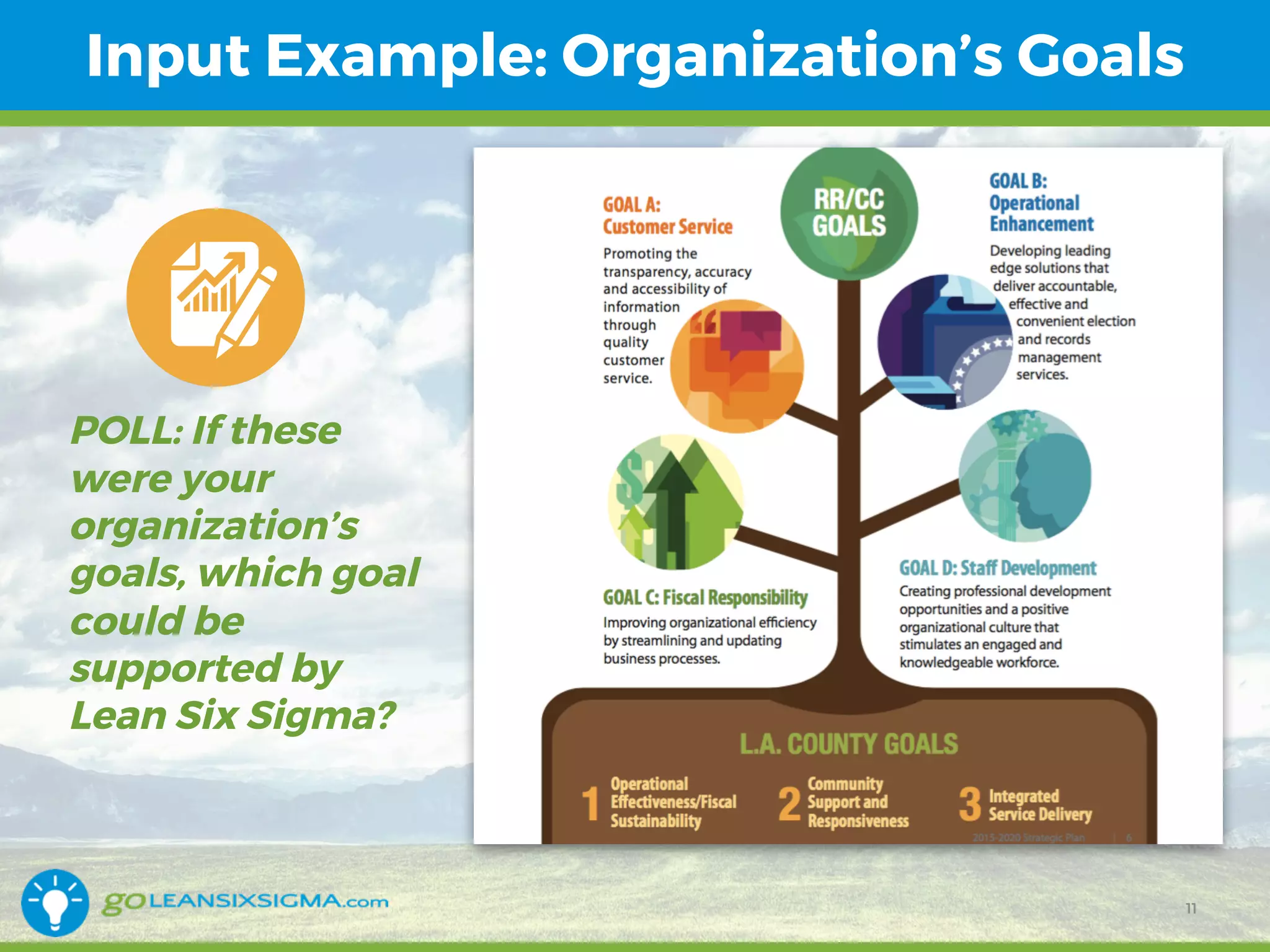

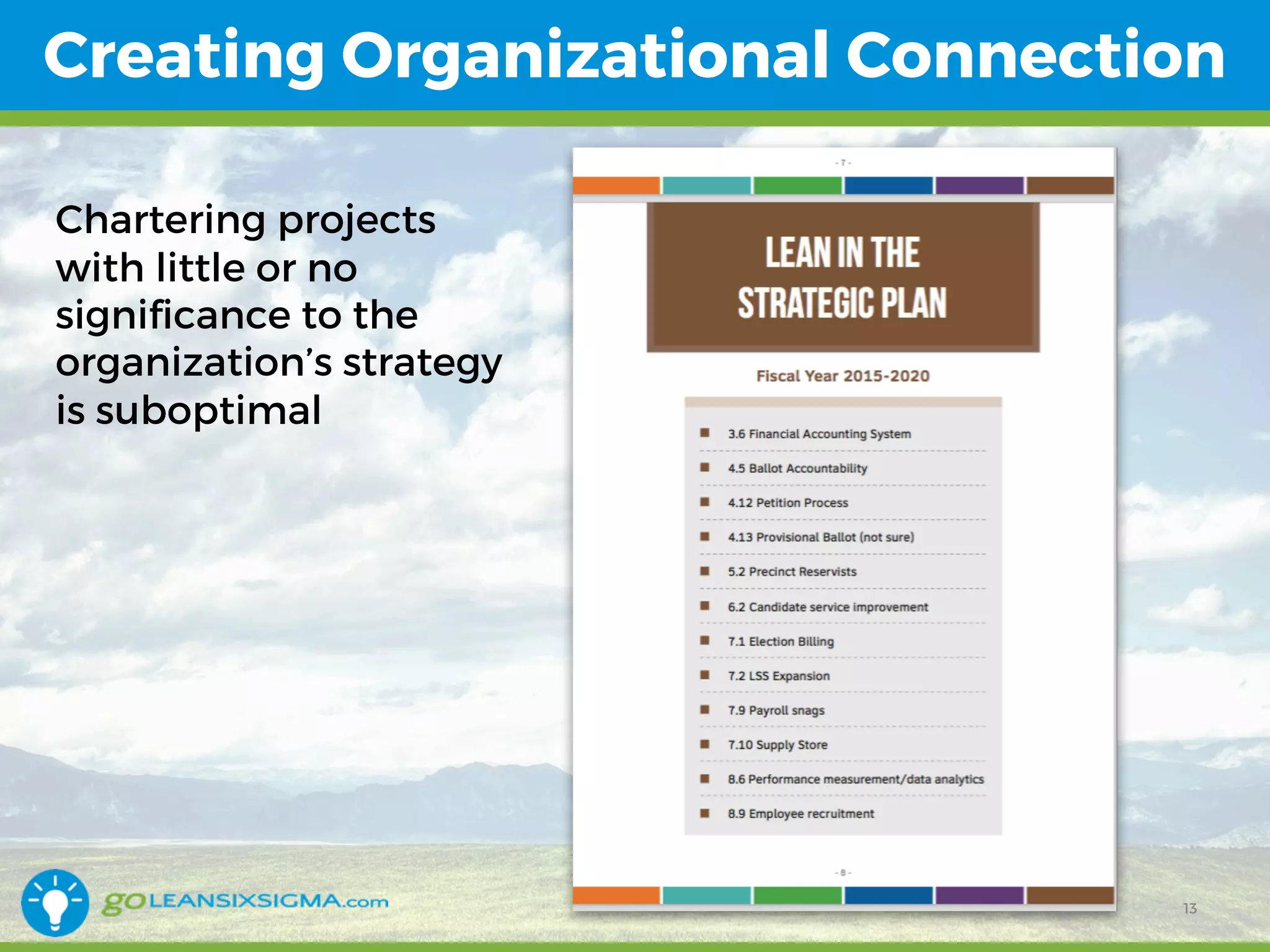

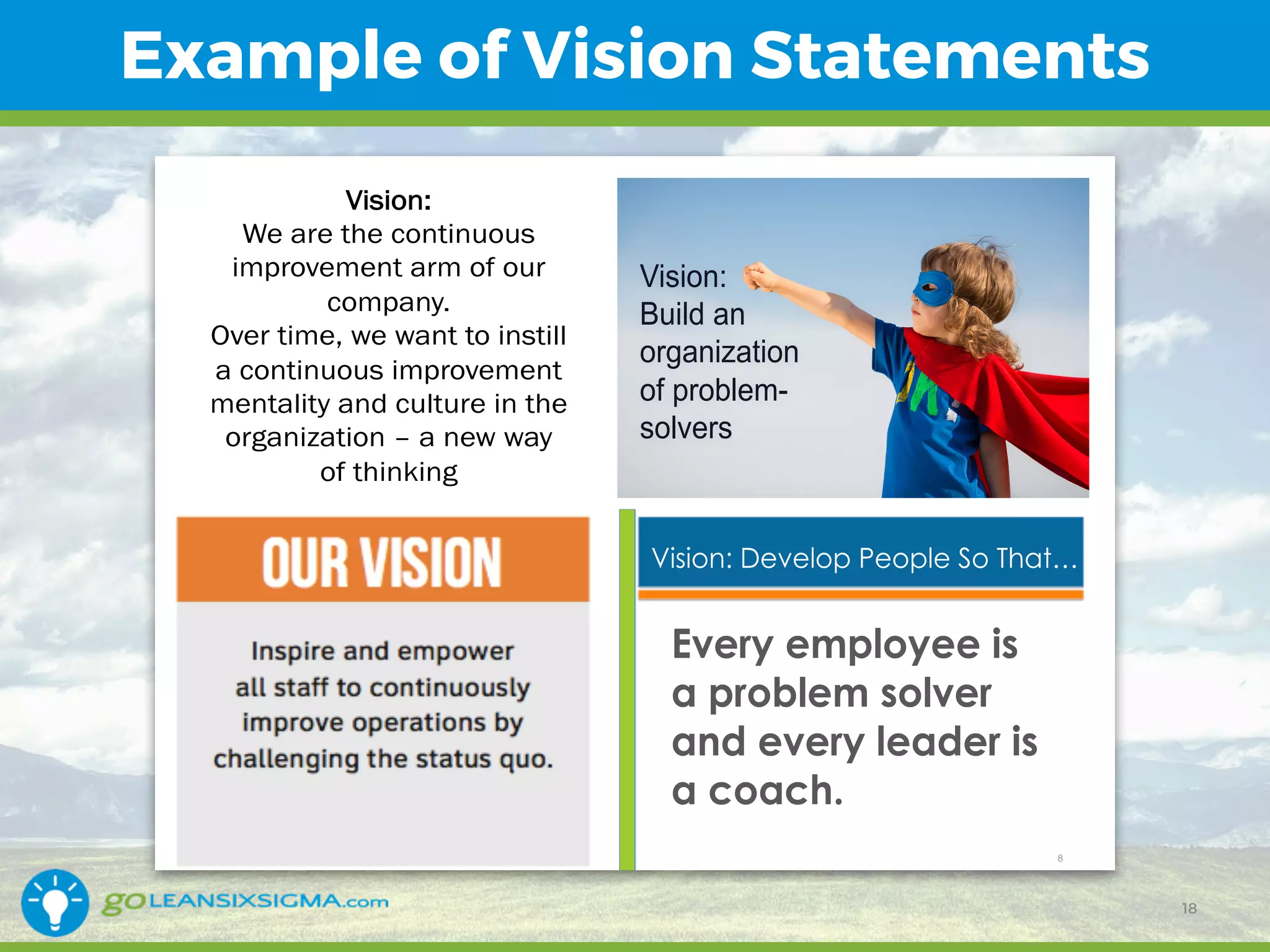

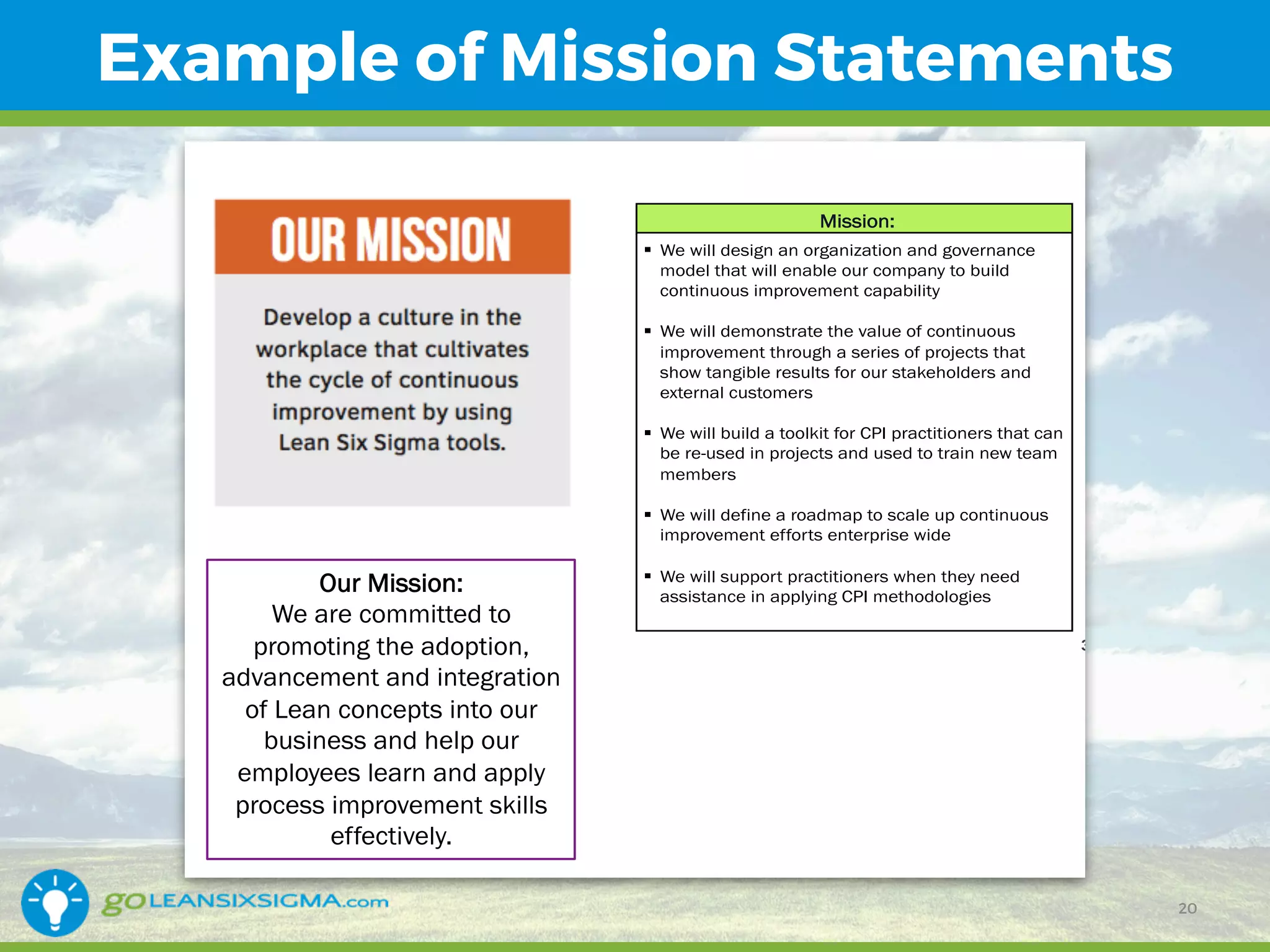

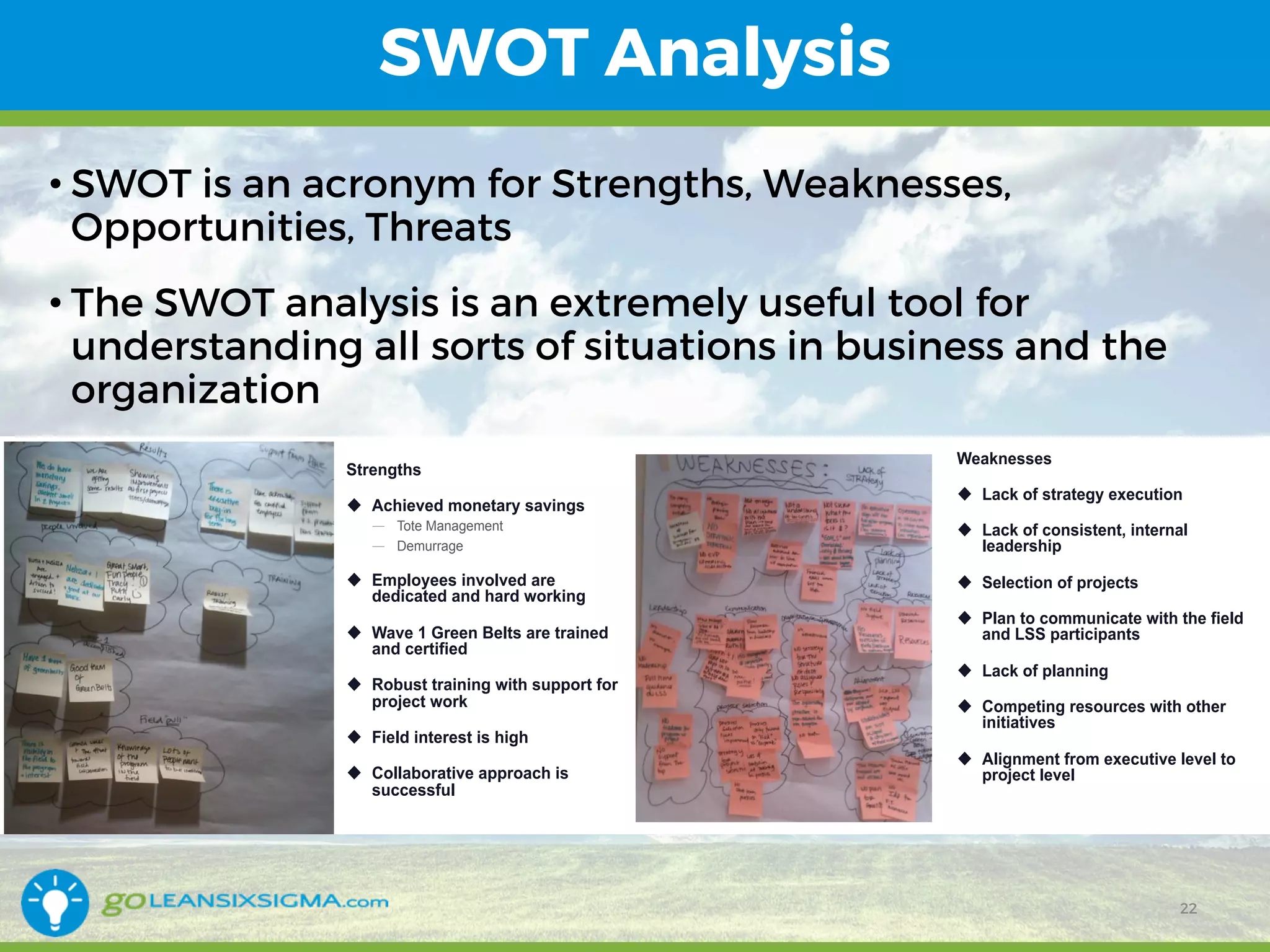

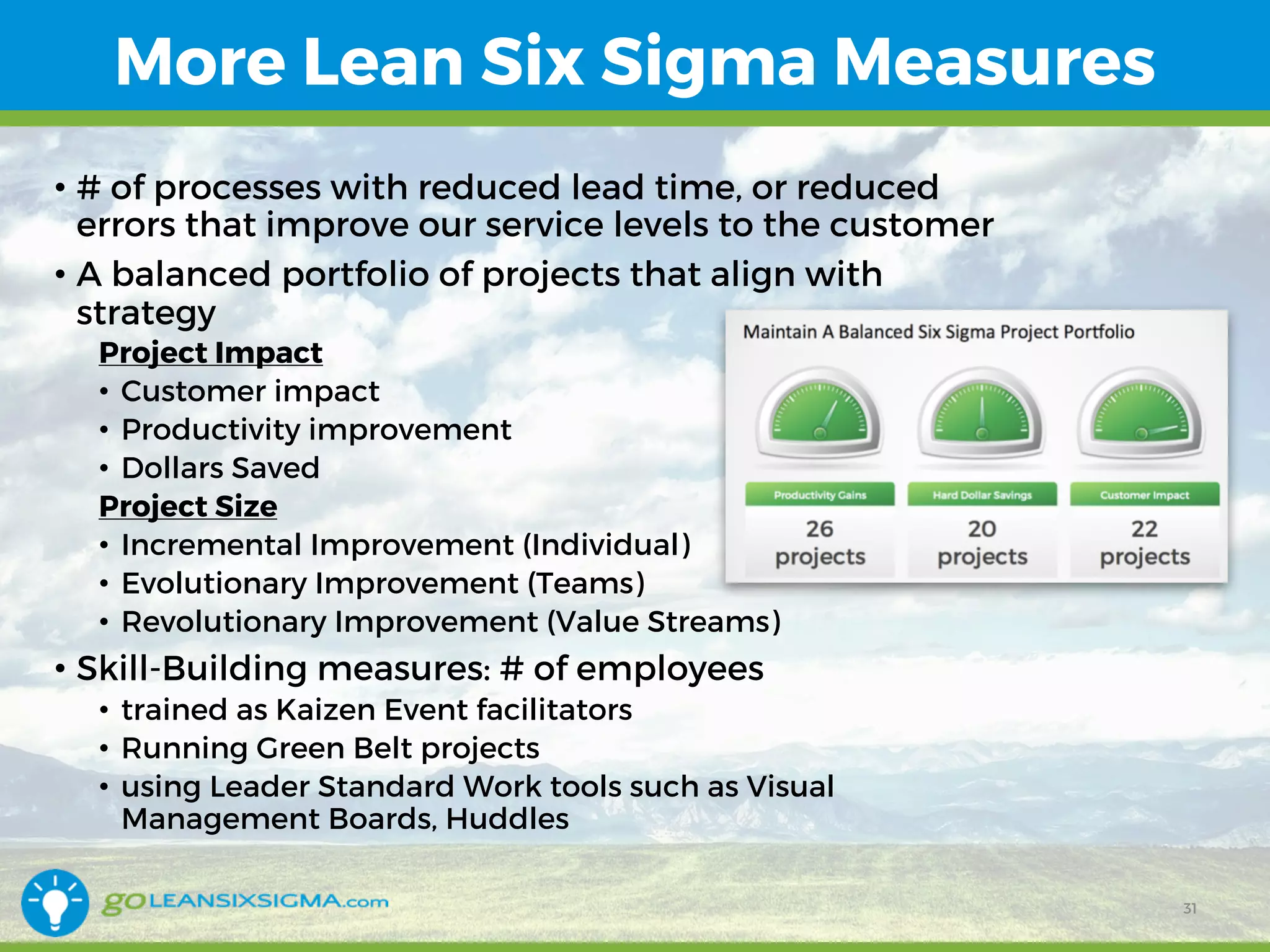

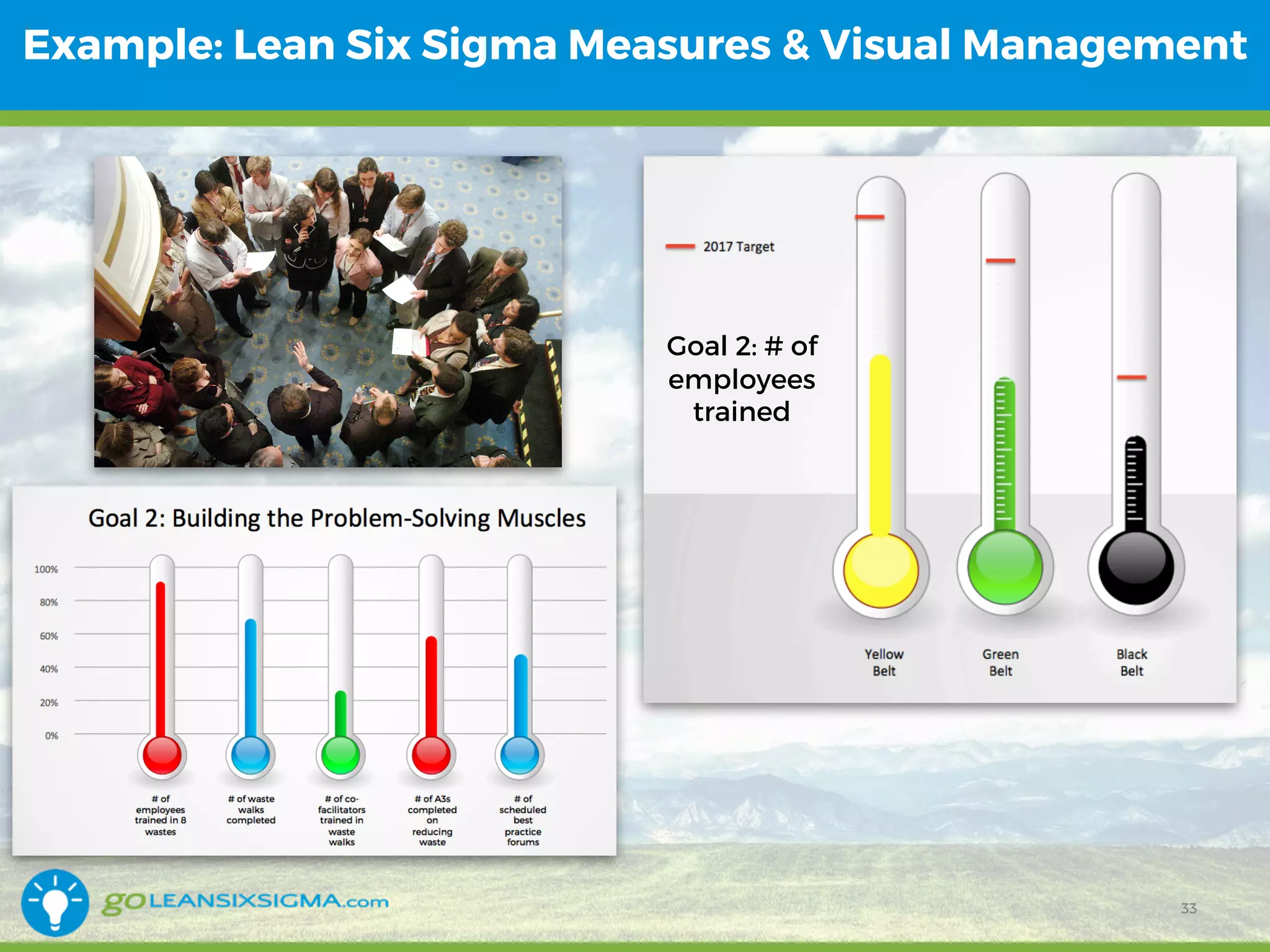

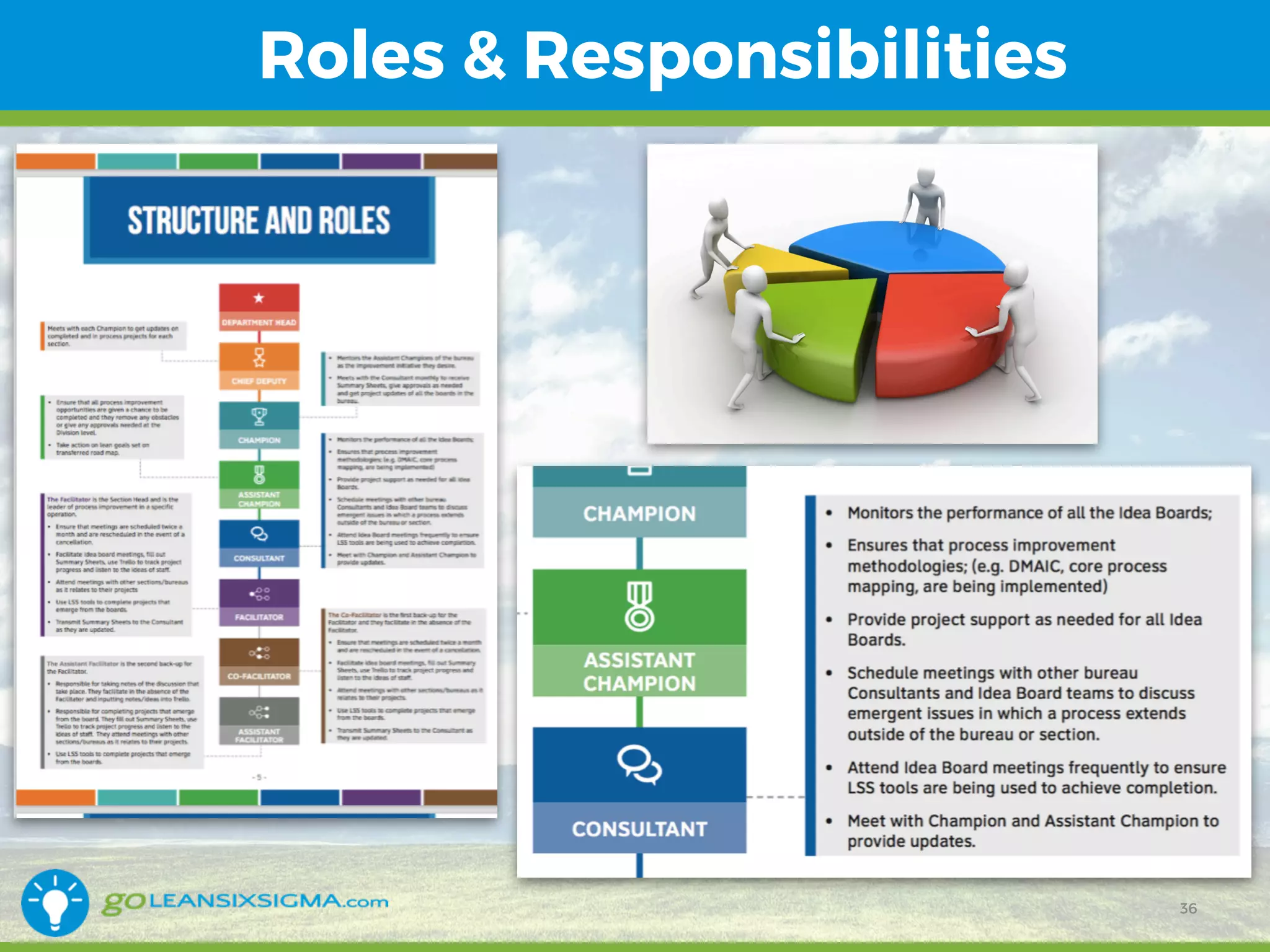

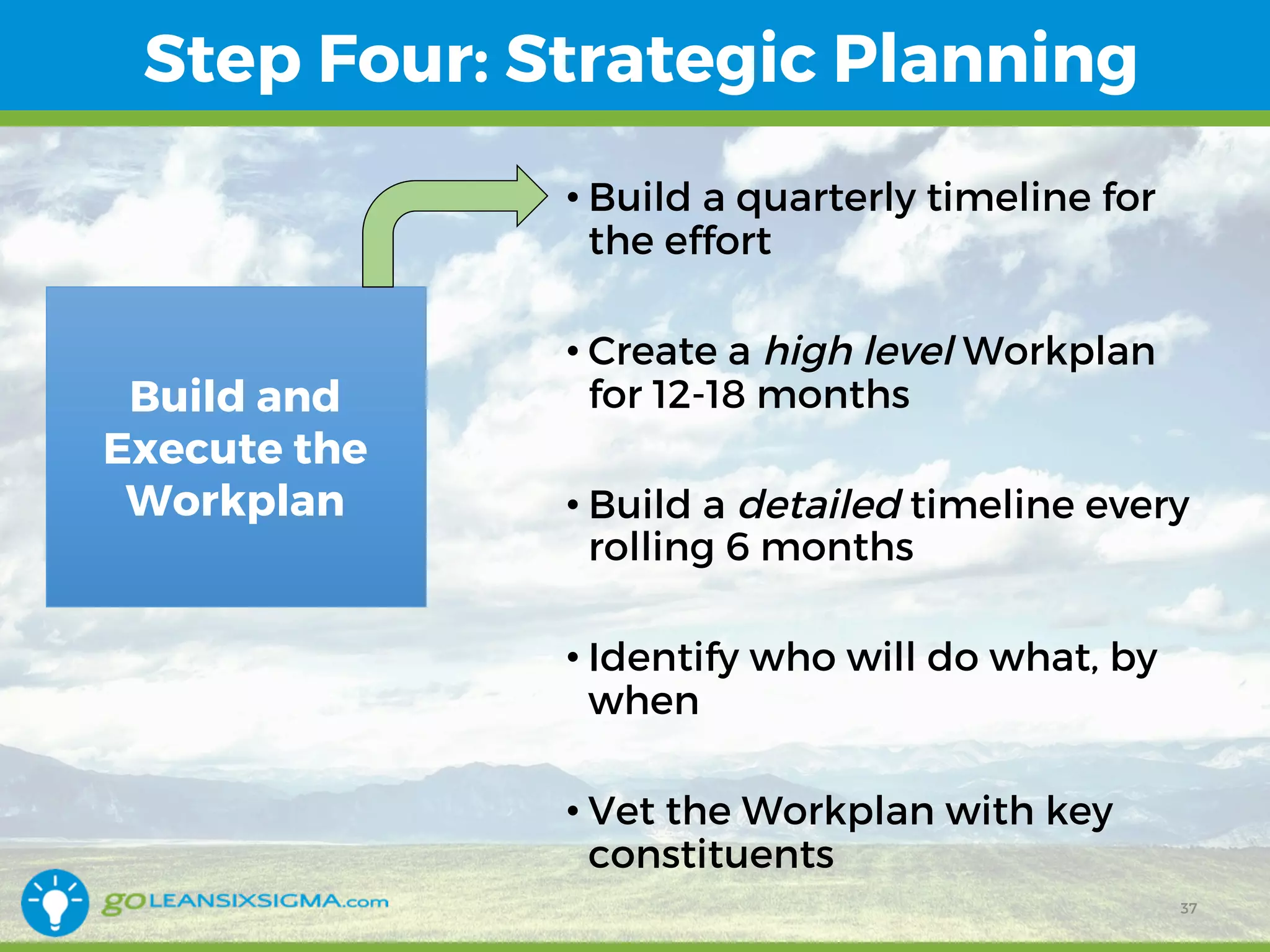

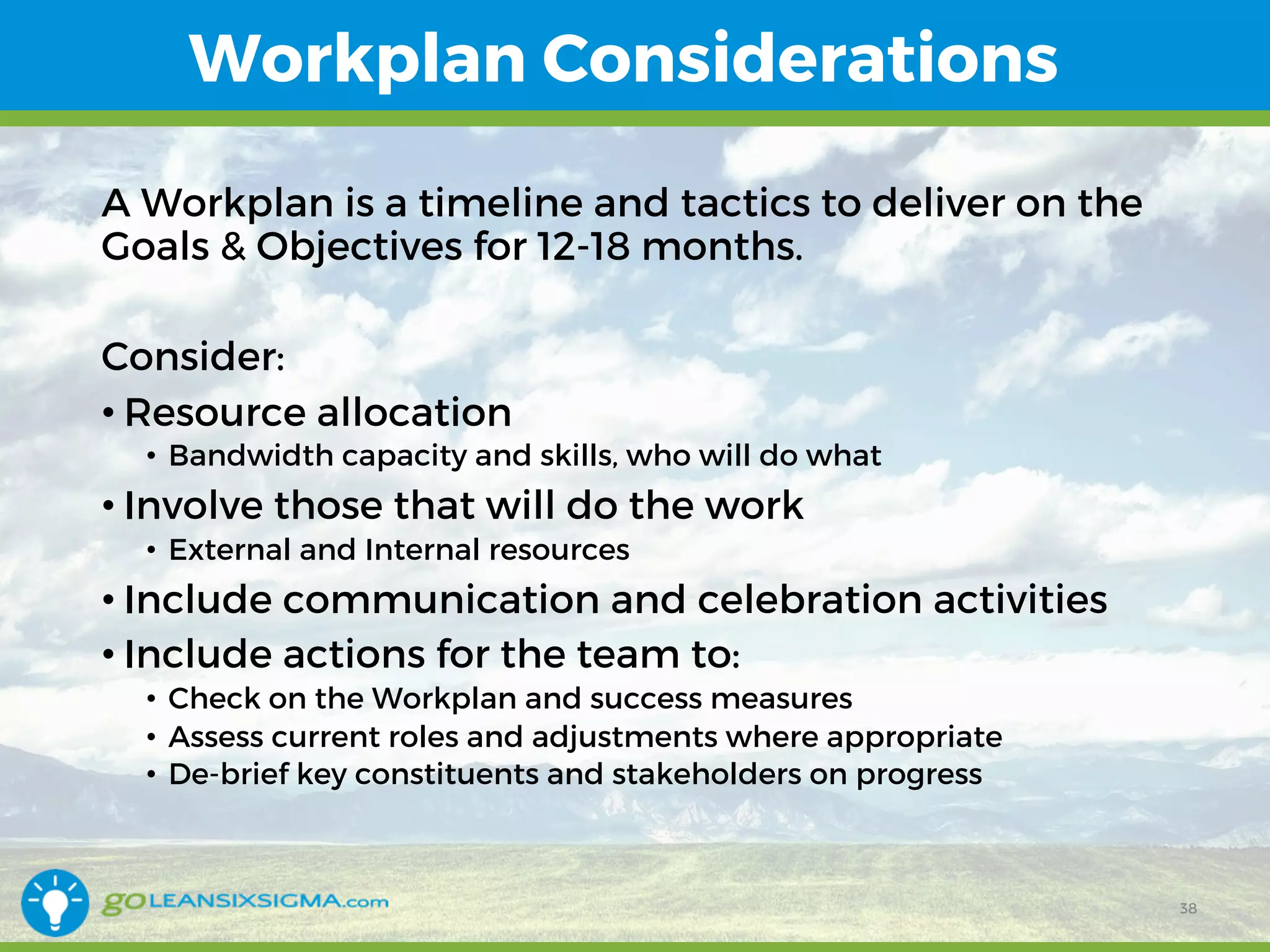

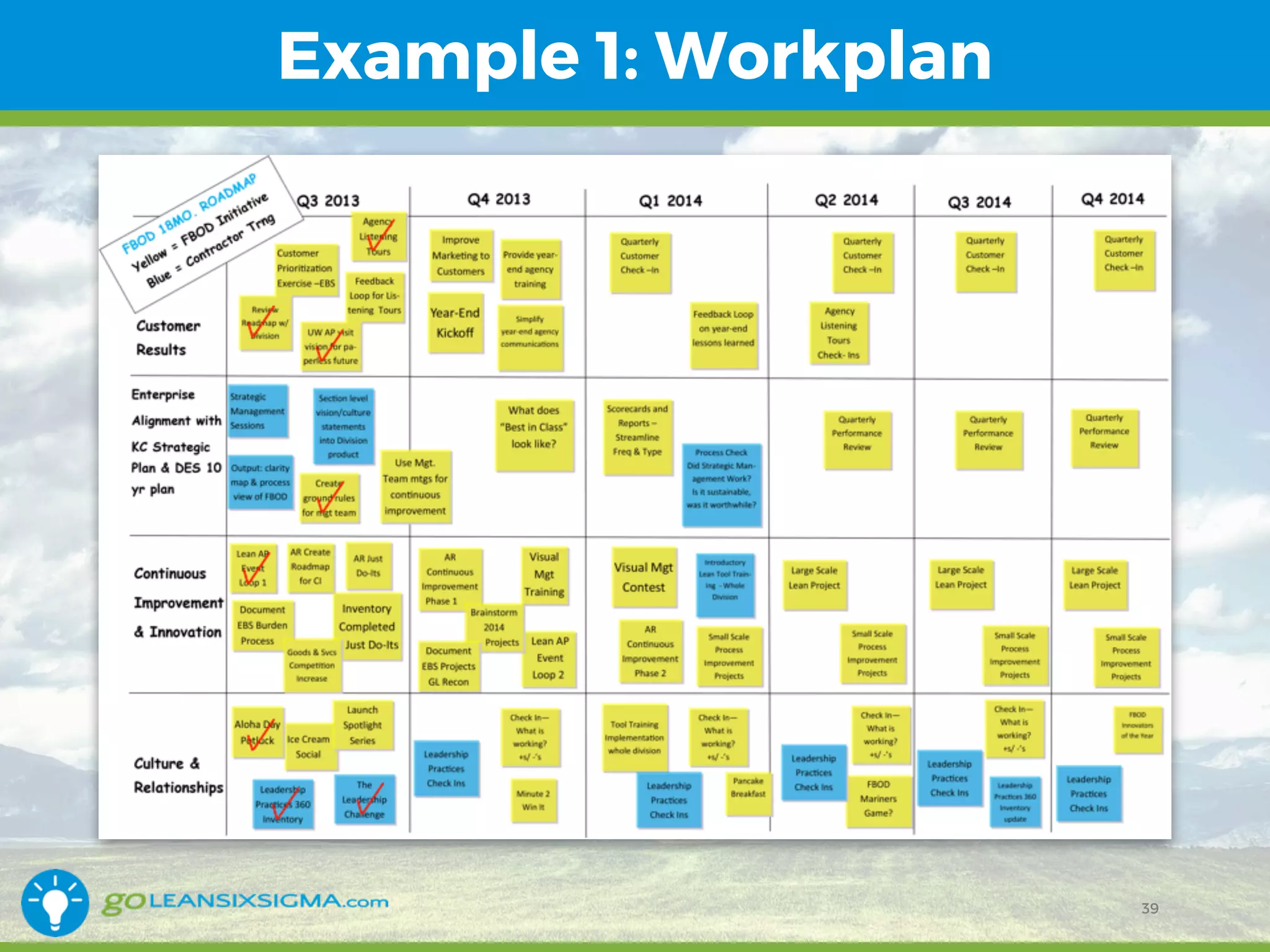

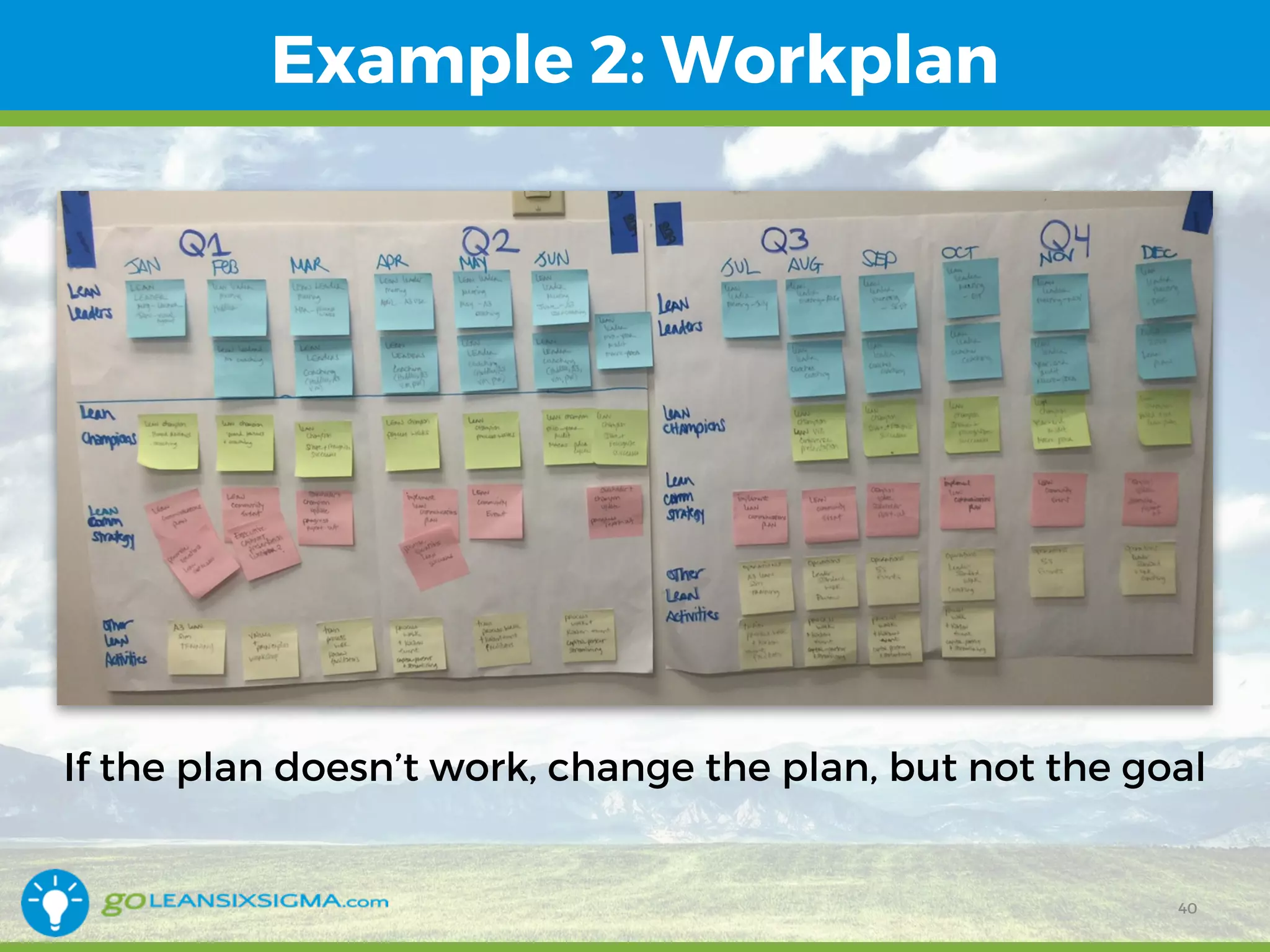

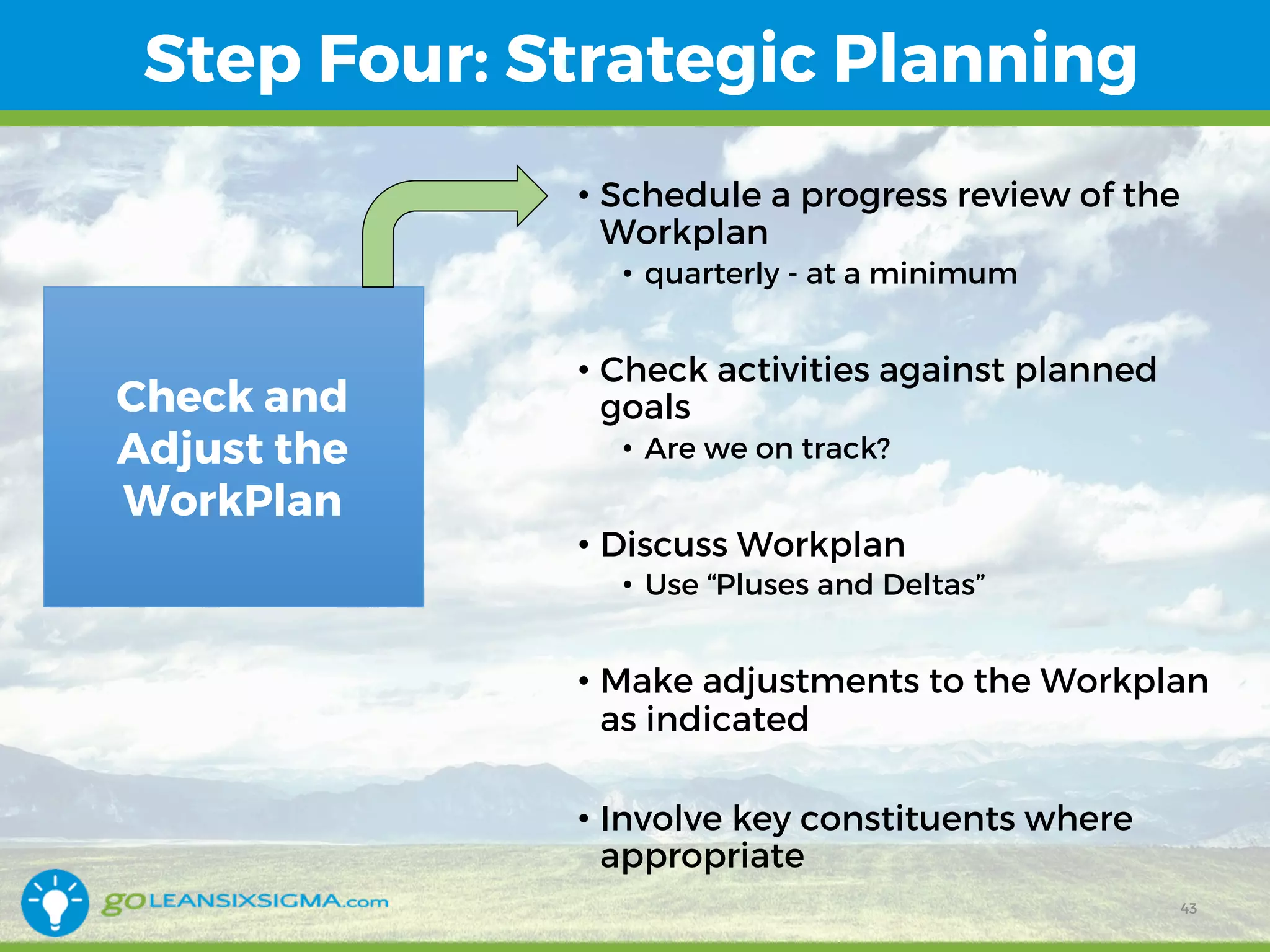

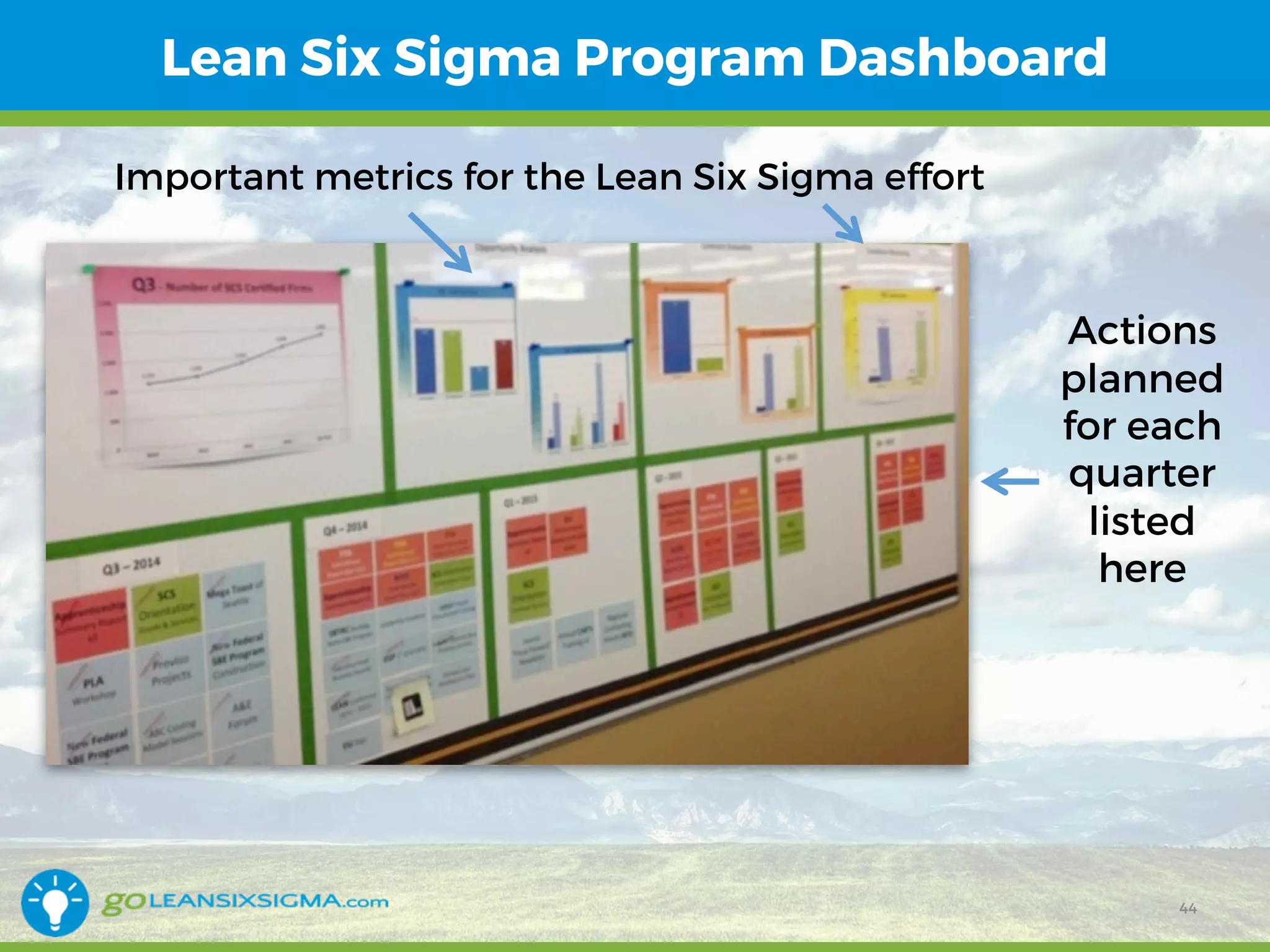

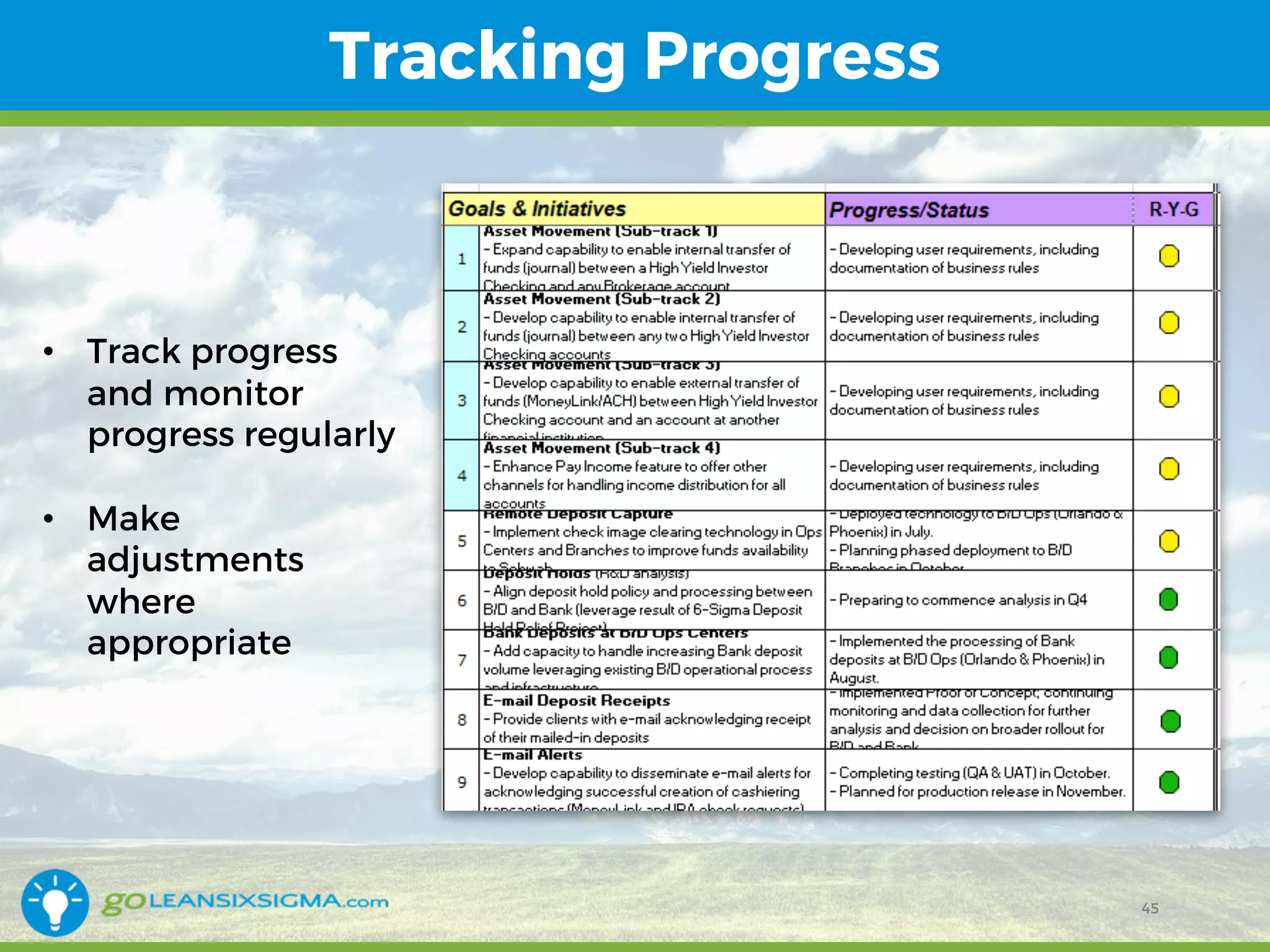

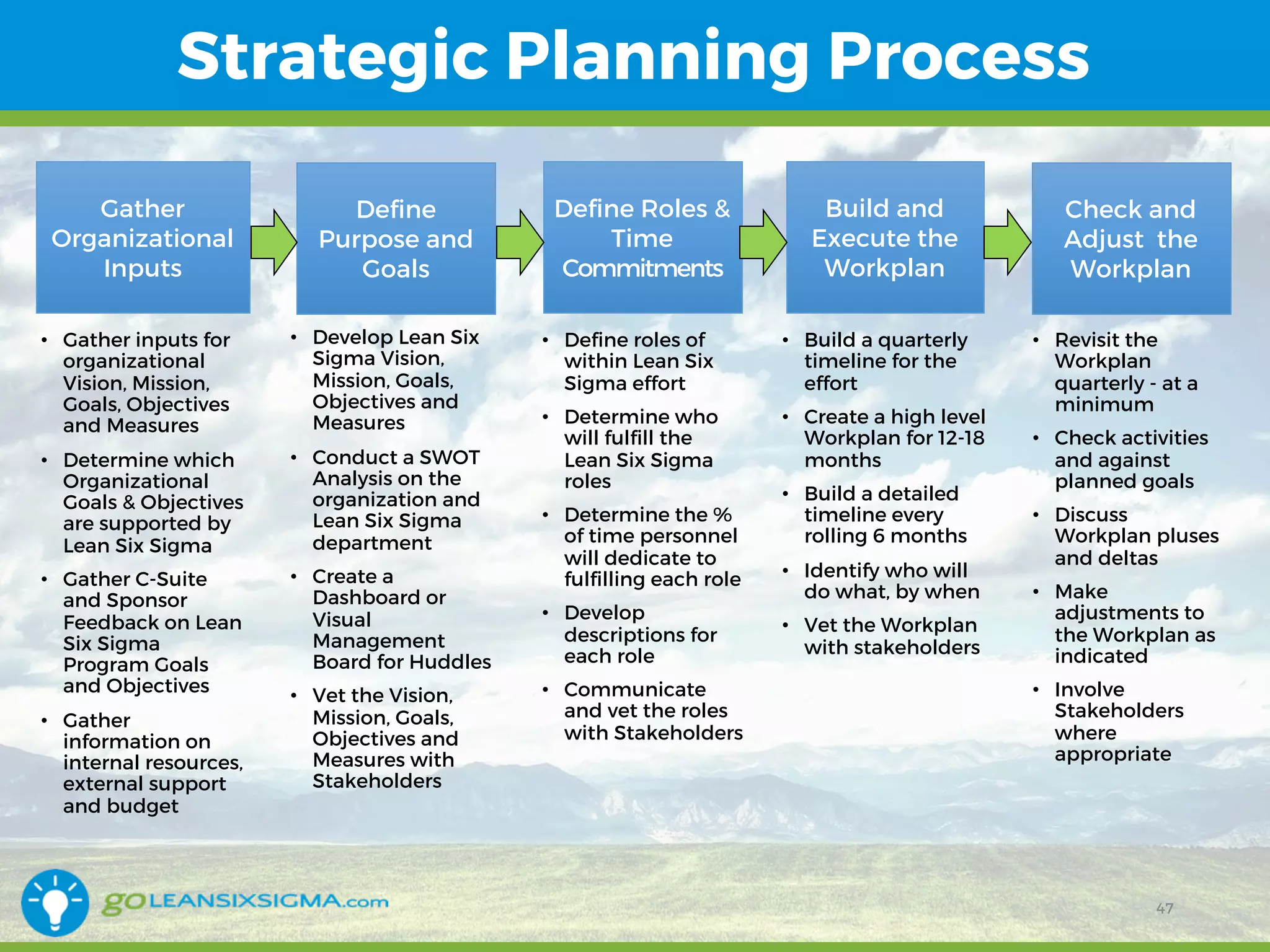

The document presents a guide on creating a strategic plan for a Lean Six Sigma program office, outlining the importance of strategic planning, the process of gathering organizational inputs, and developing a vision, mission, goals, and objectives. It emphasizes the importance of defining roles and responsibilities, building a workplan, and regularly checking progress to ensure alignment with organizational strategy and continuous improvement. The guide provides practical steps and examples to engage stakeholders and measure success.