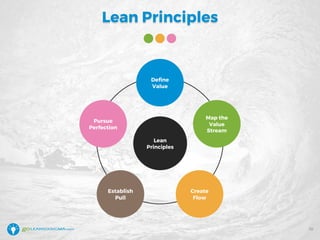

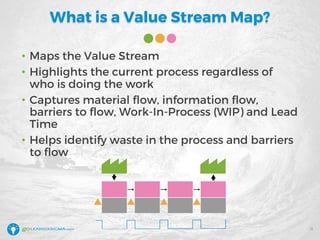

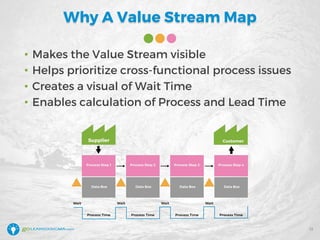

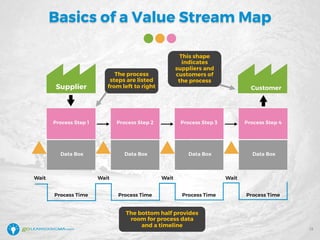

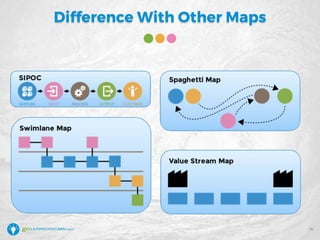

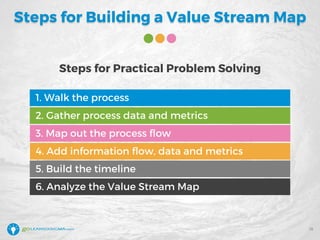

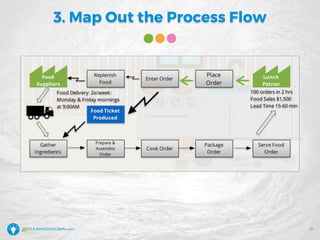

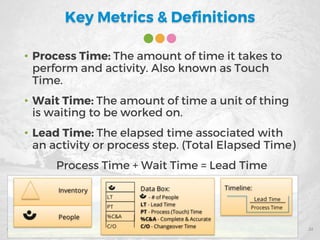

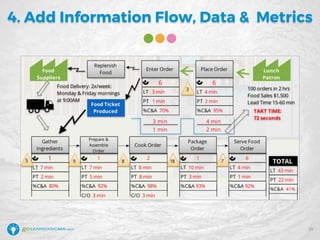

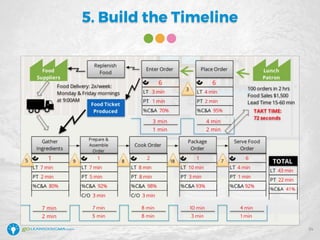

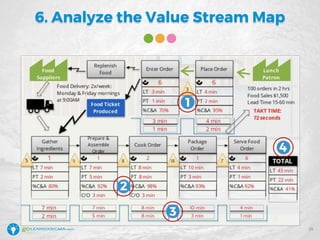

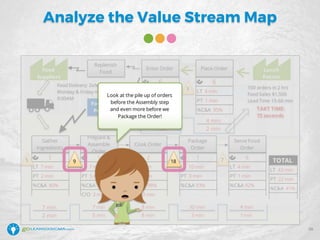

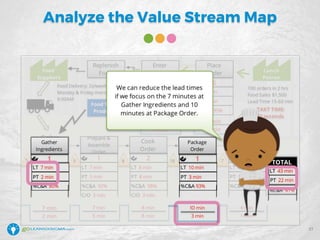

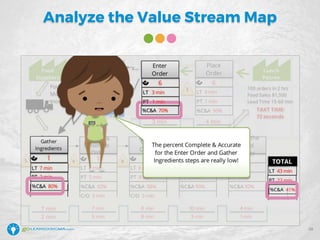

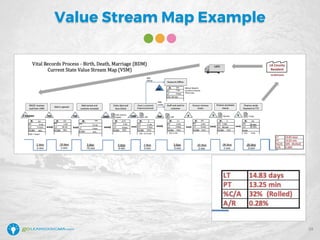

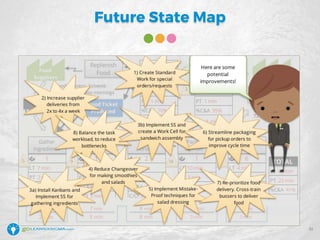

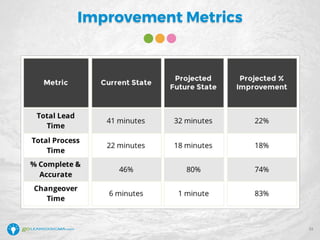

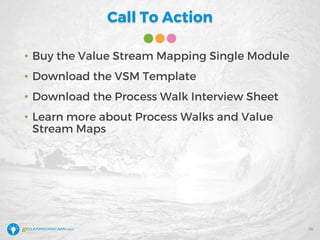

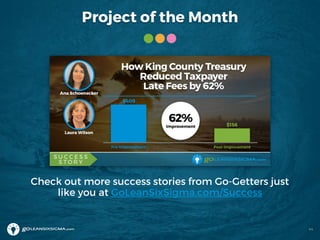

Tracy O’Rourke's webinar introduces value stream mapping, outlining its importance in visualizing processes and identifying waste. Participants learn to define, build, and analyze value stream maps, supported by practical steps and metrics. The session emphasizes community engagement and provides resources for ongoing learning in process improvement.