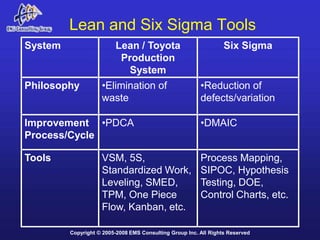

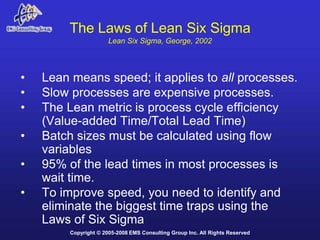

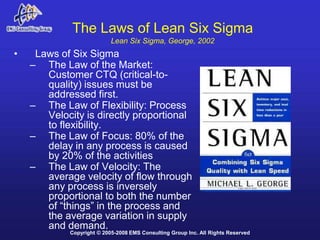

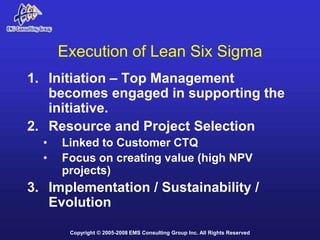

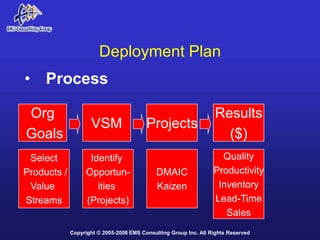

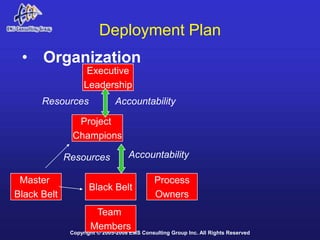

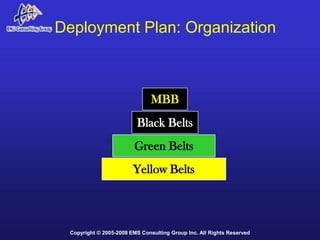

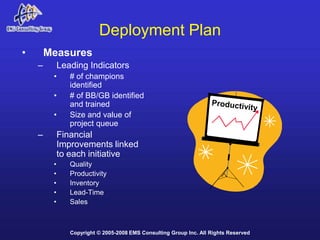

The document outlines the implementation of Lean Six Sigma, combining Lean tools and Six Sigma methodologies to enhance process efficiency by eliminating waste and defects. It discusses key principles, such as the laws of Lean Six Sigma, which highlight the importance of addressing customer quality issues, maintaining flexibility, and focusing on the most impactful activities within processes. The document further describes a structured deployment plan, including initiation, resource selection, project implementation, and measures for success.