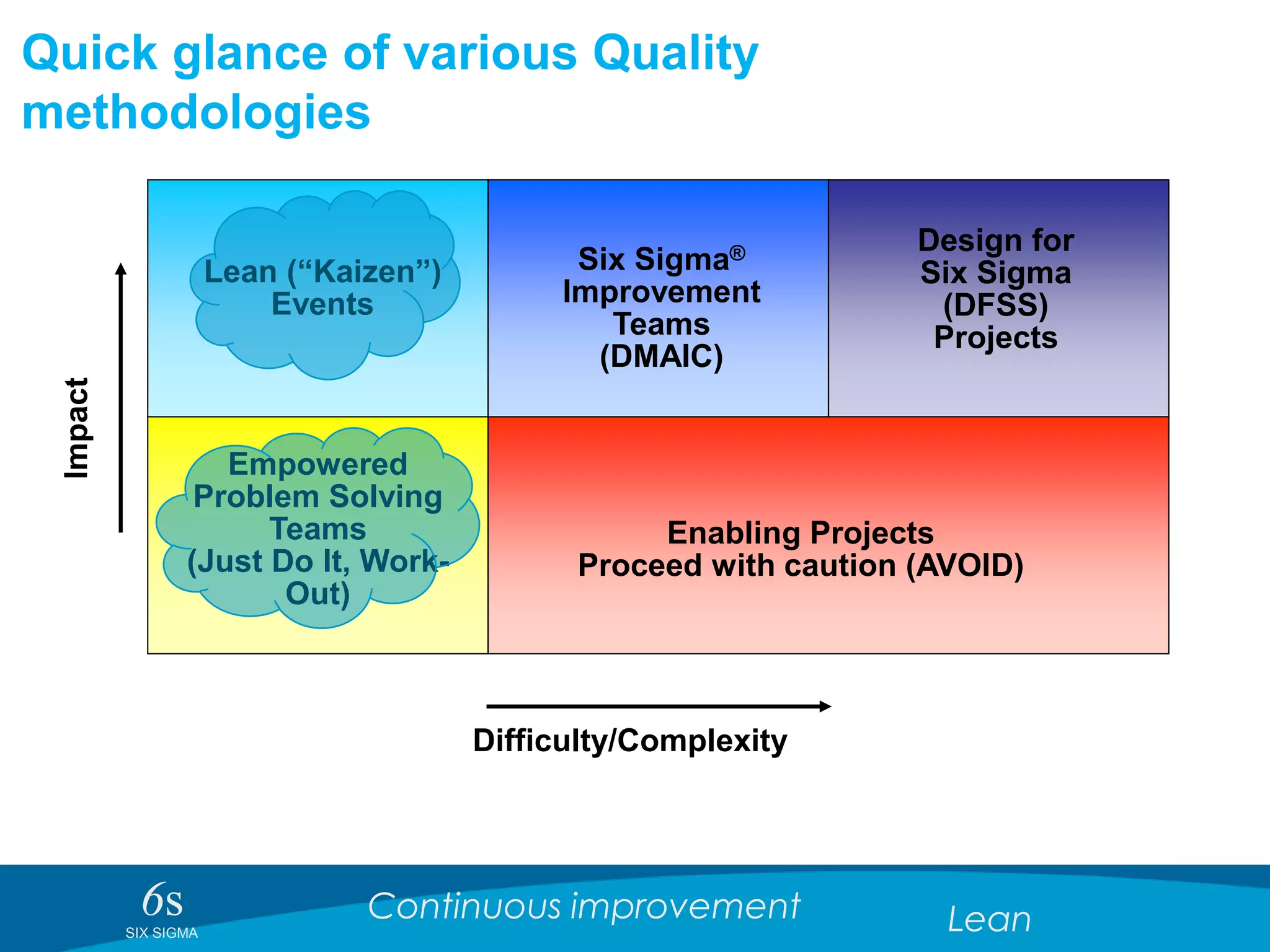

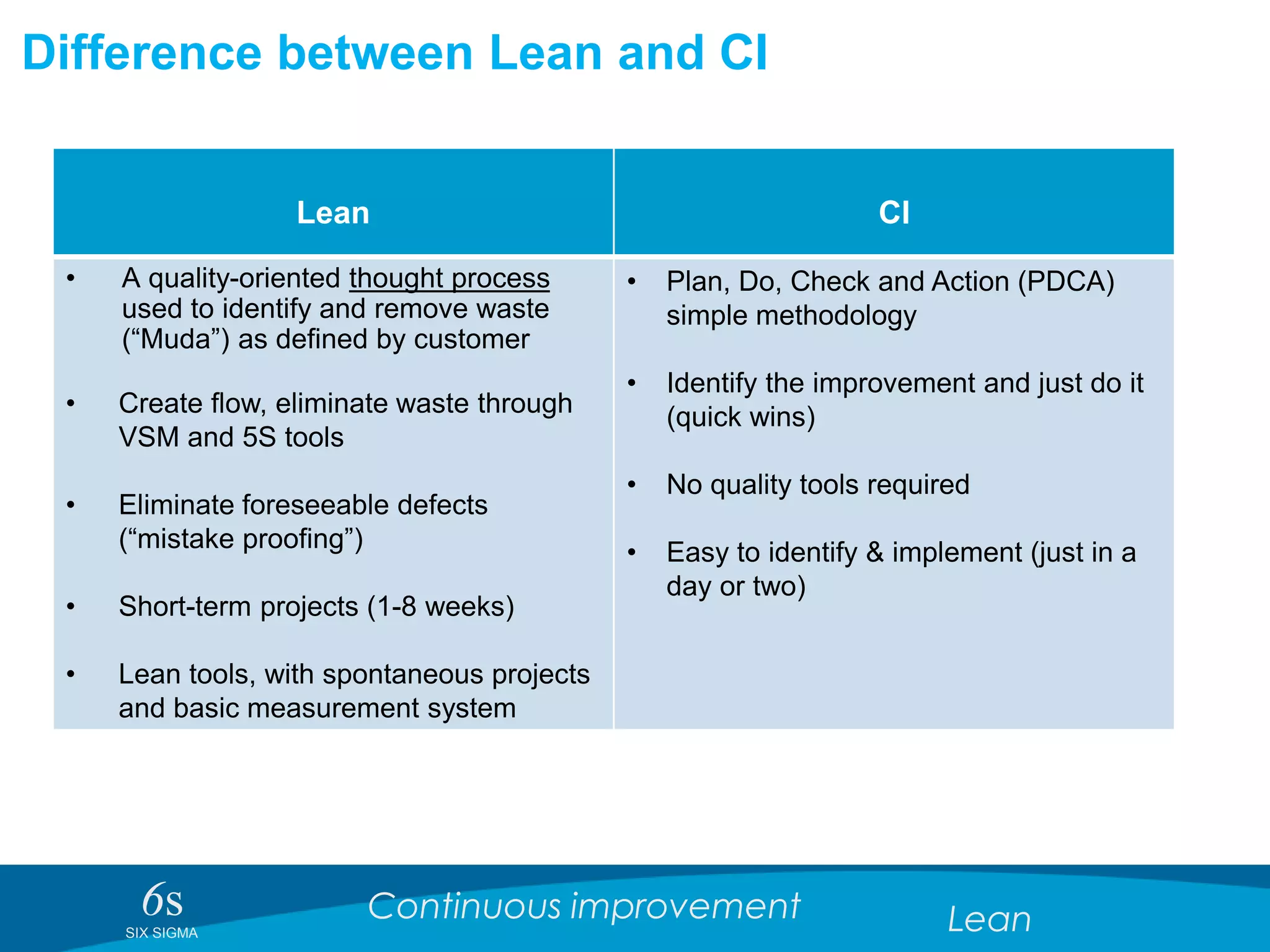

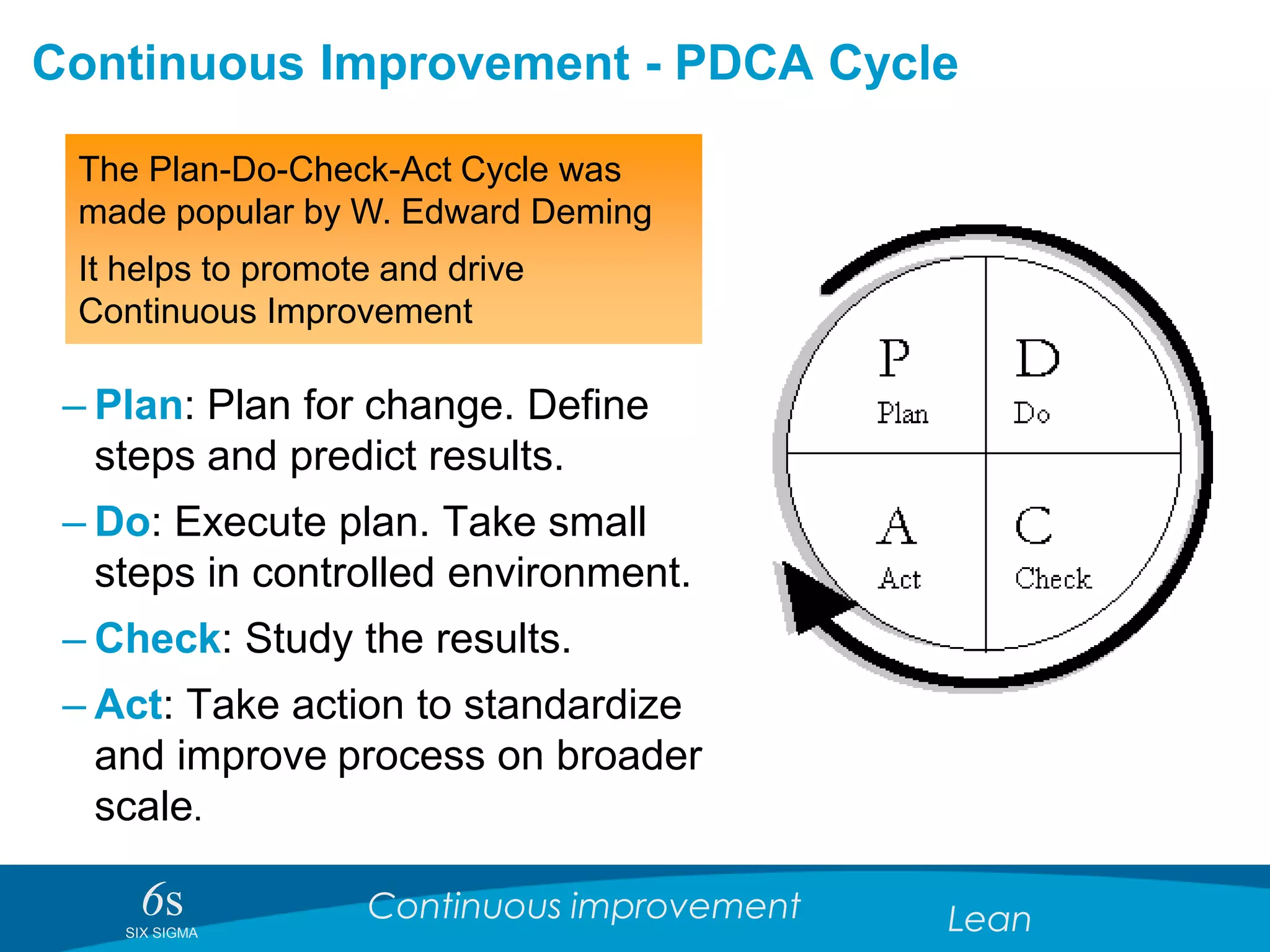

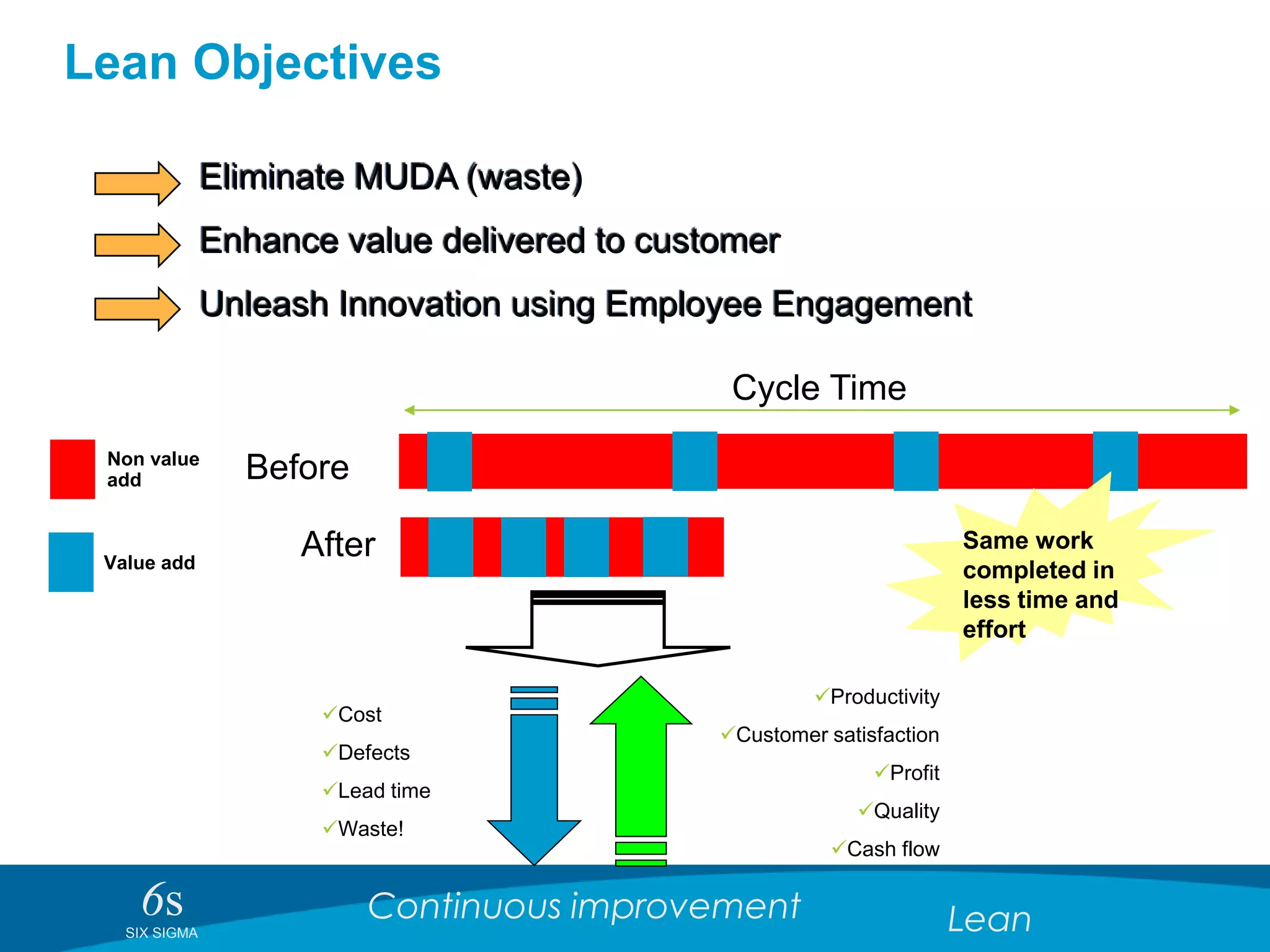

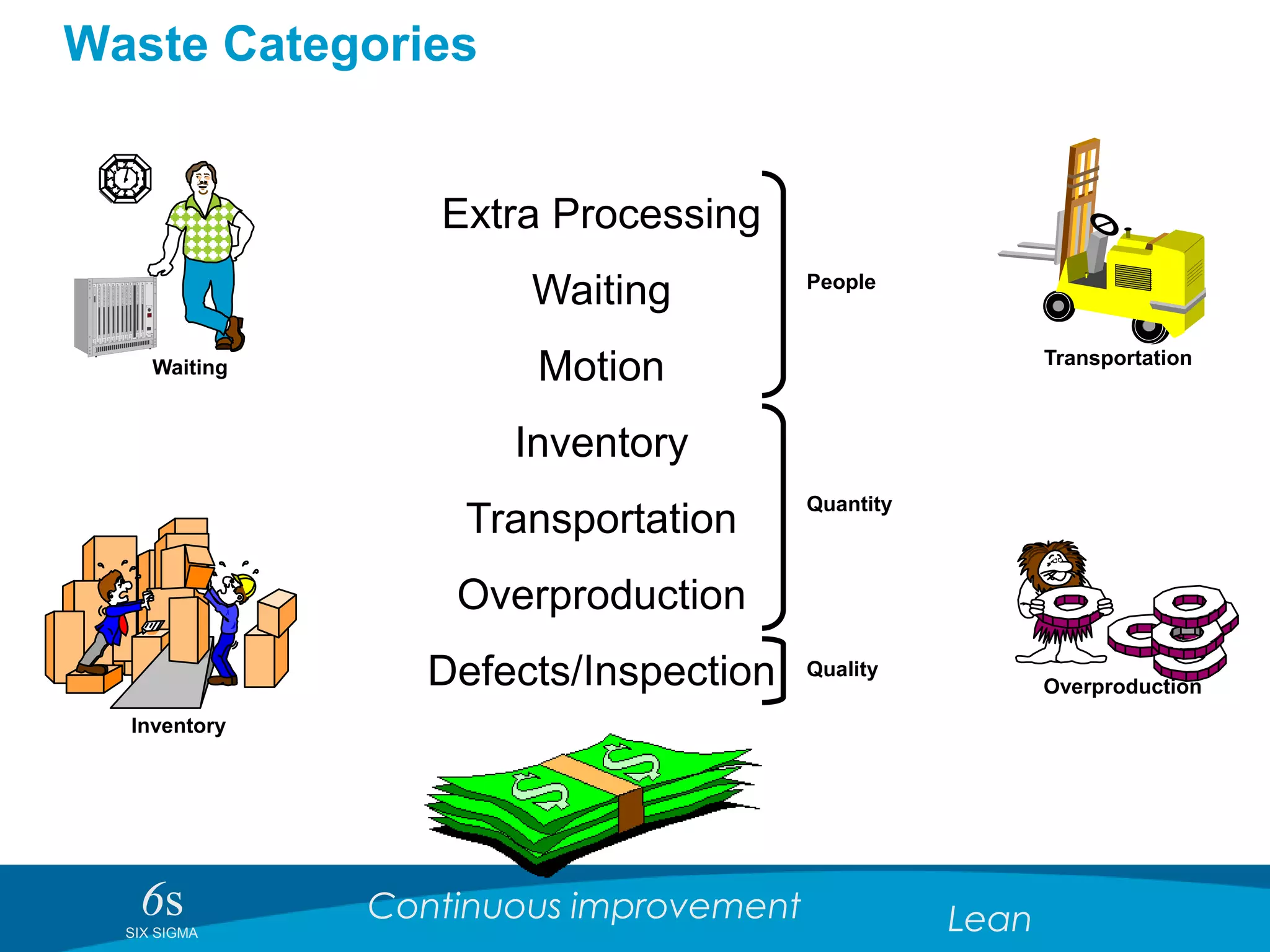

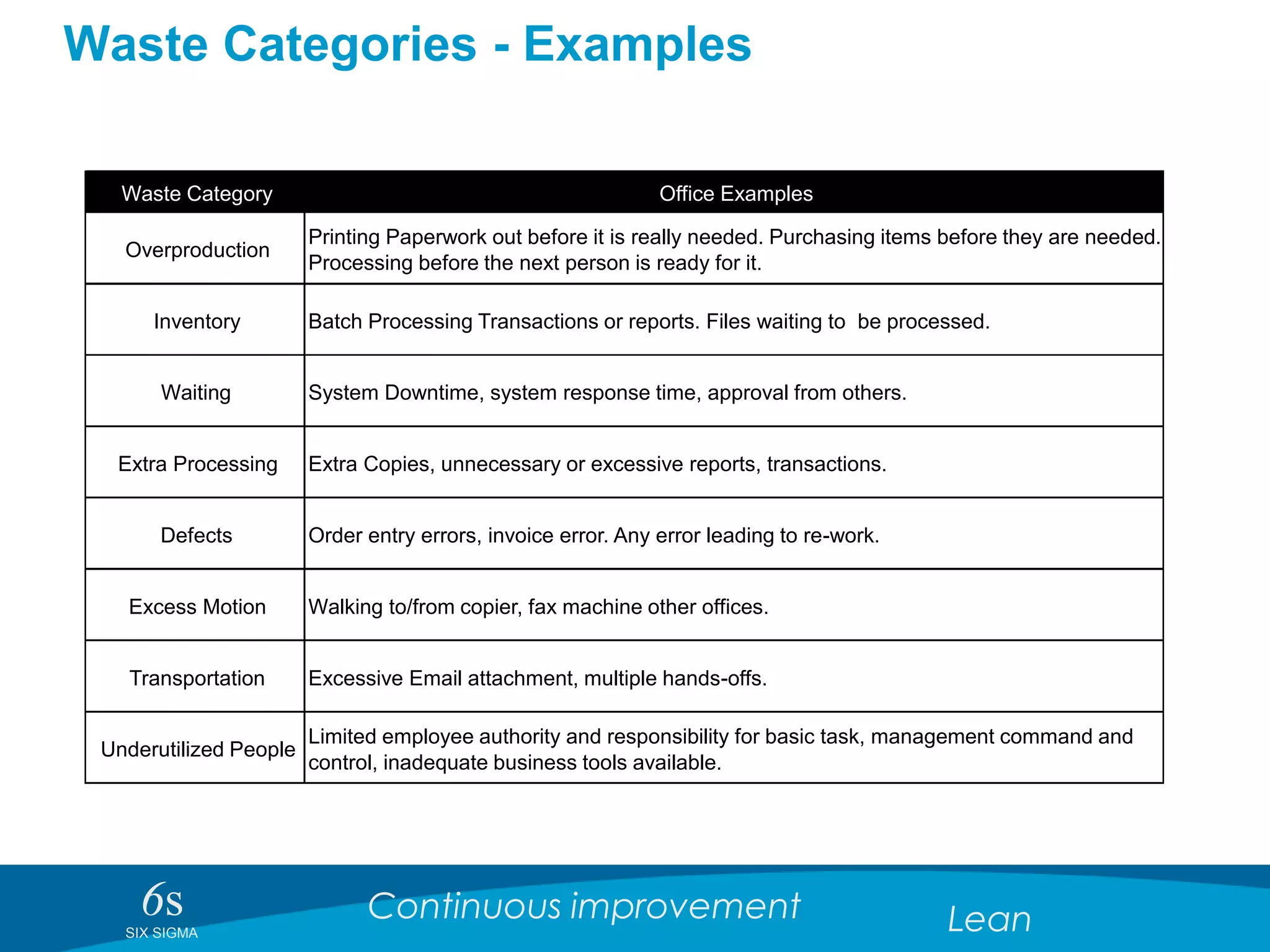

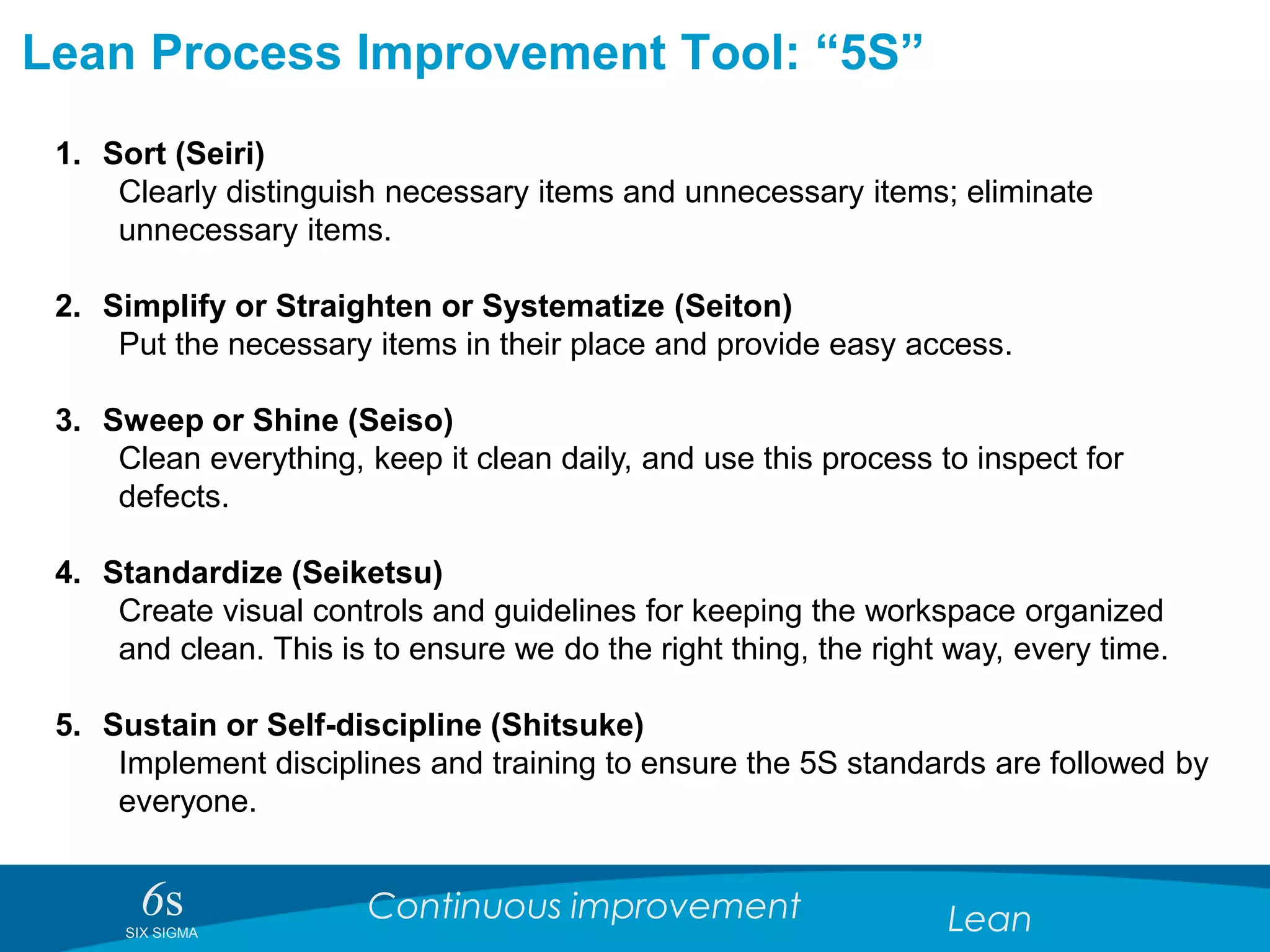

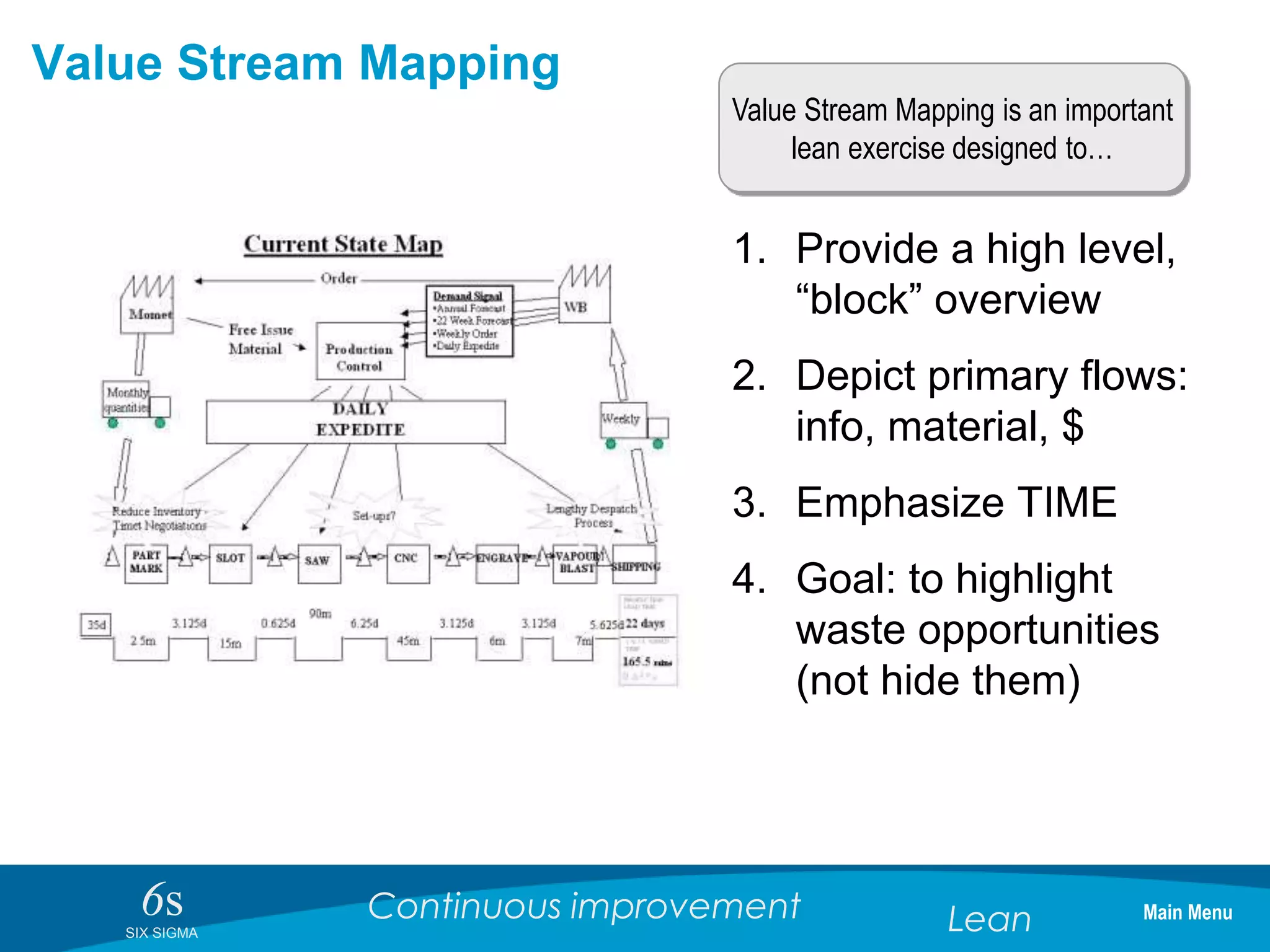

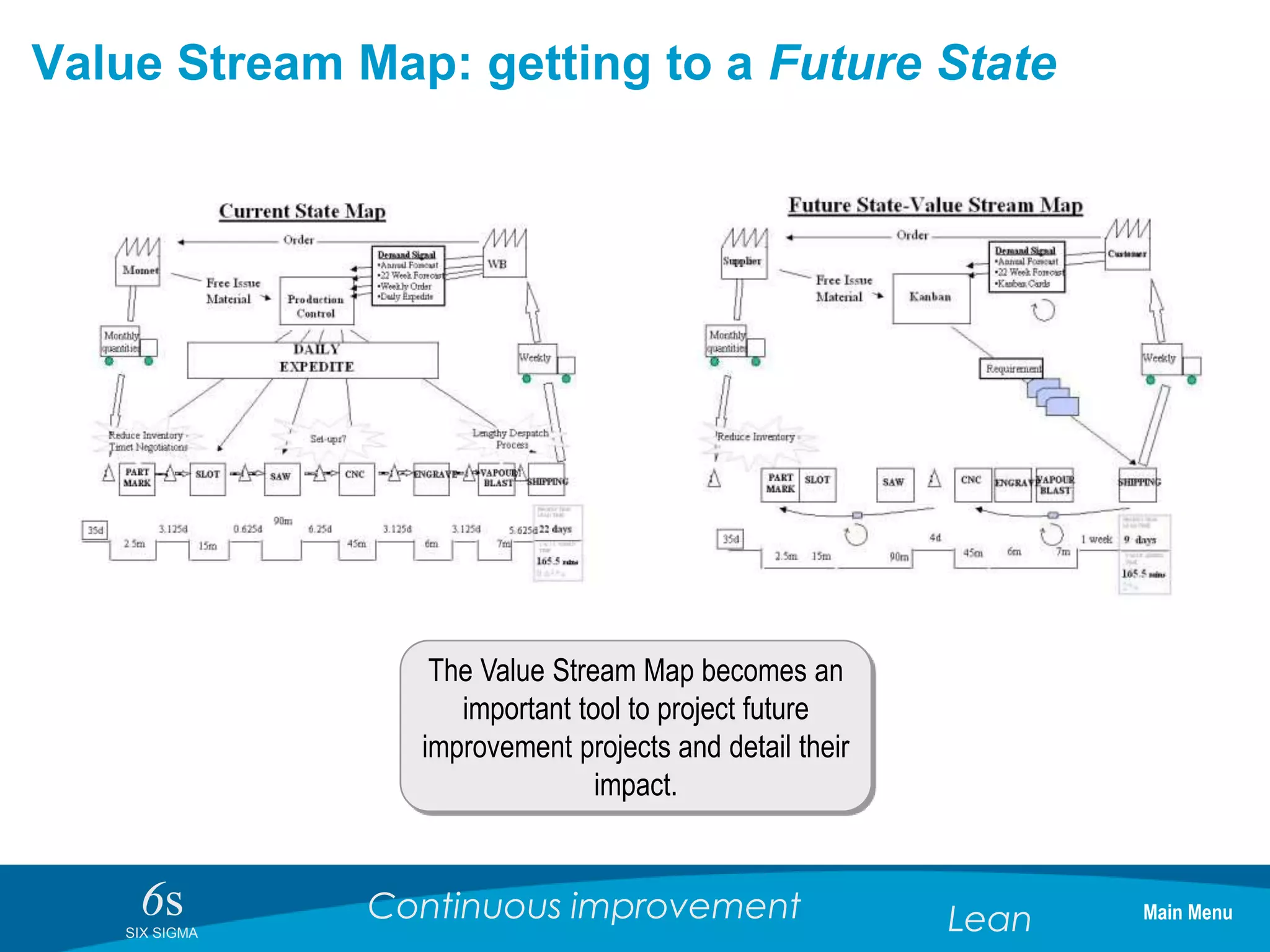

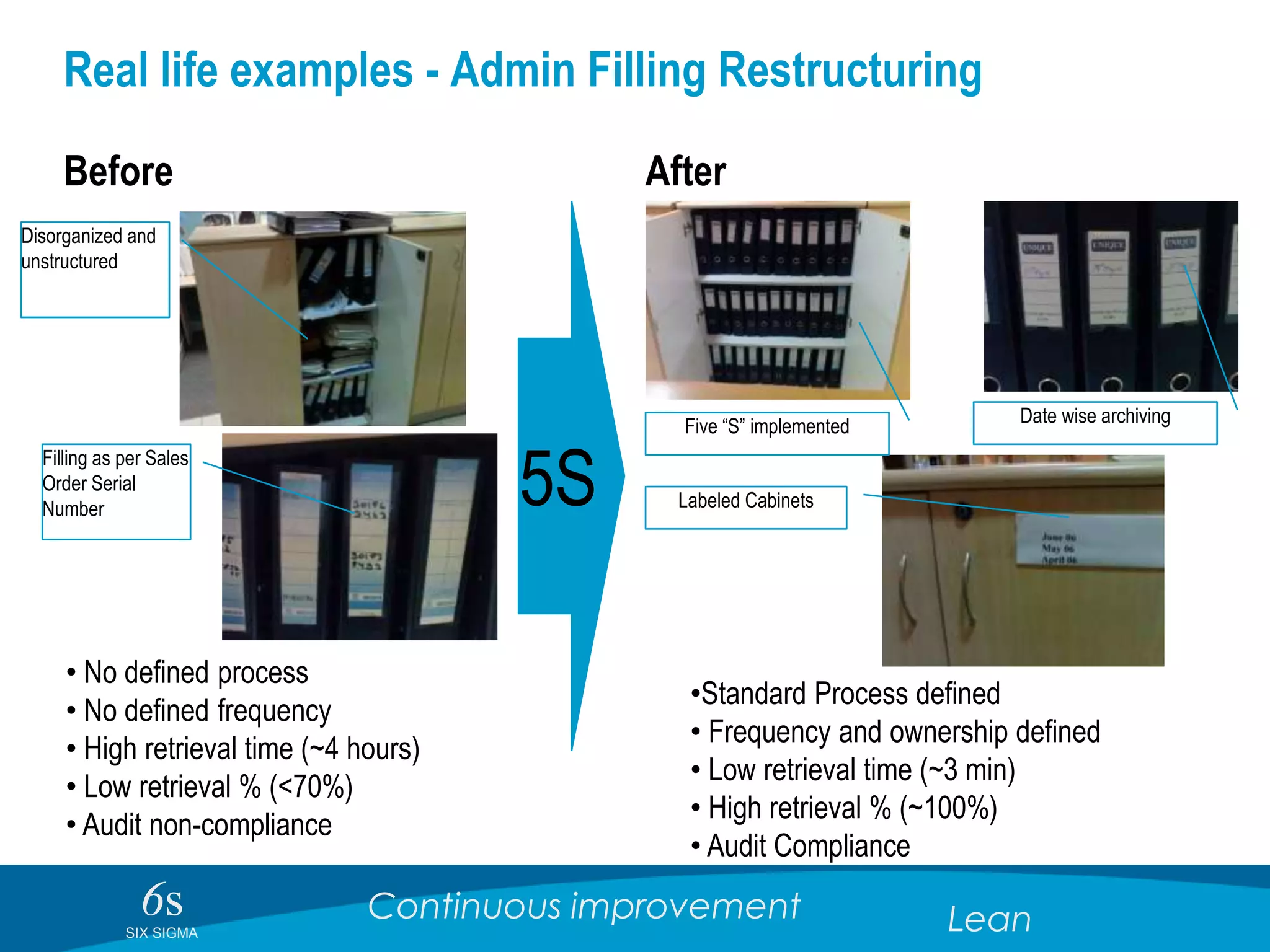

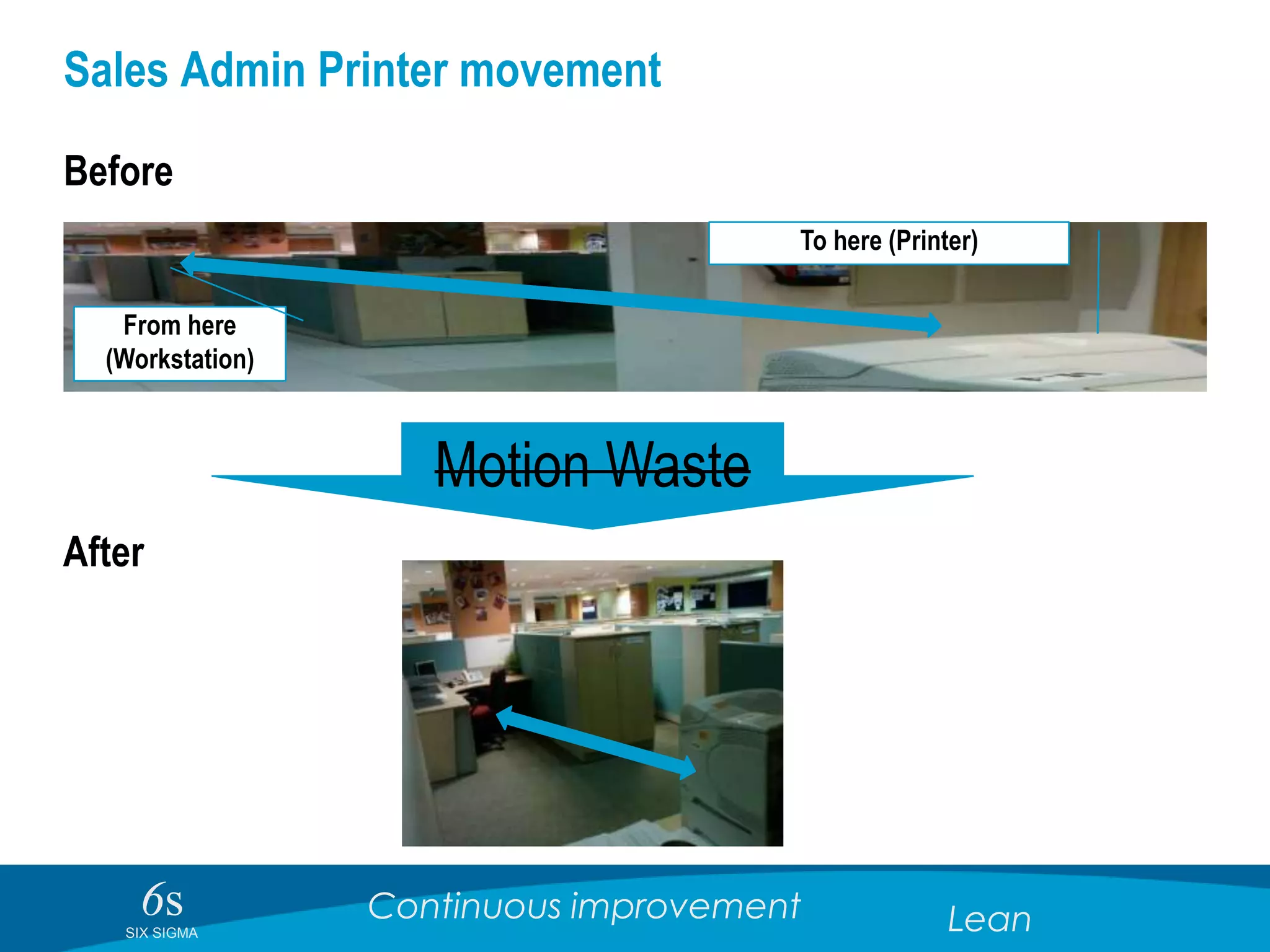

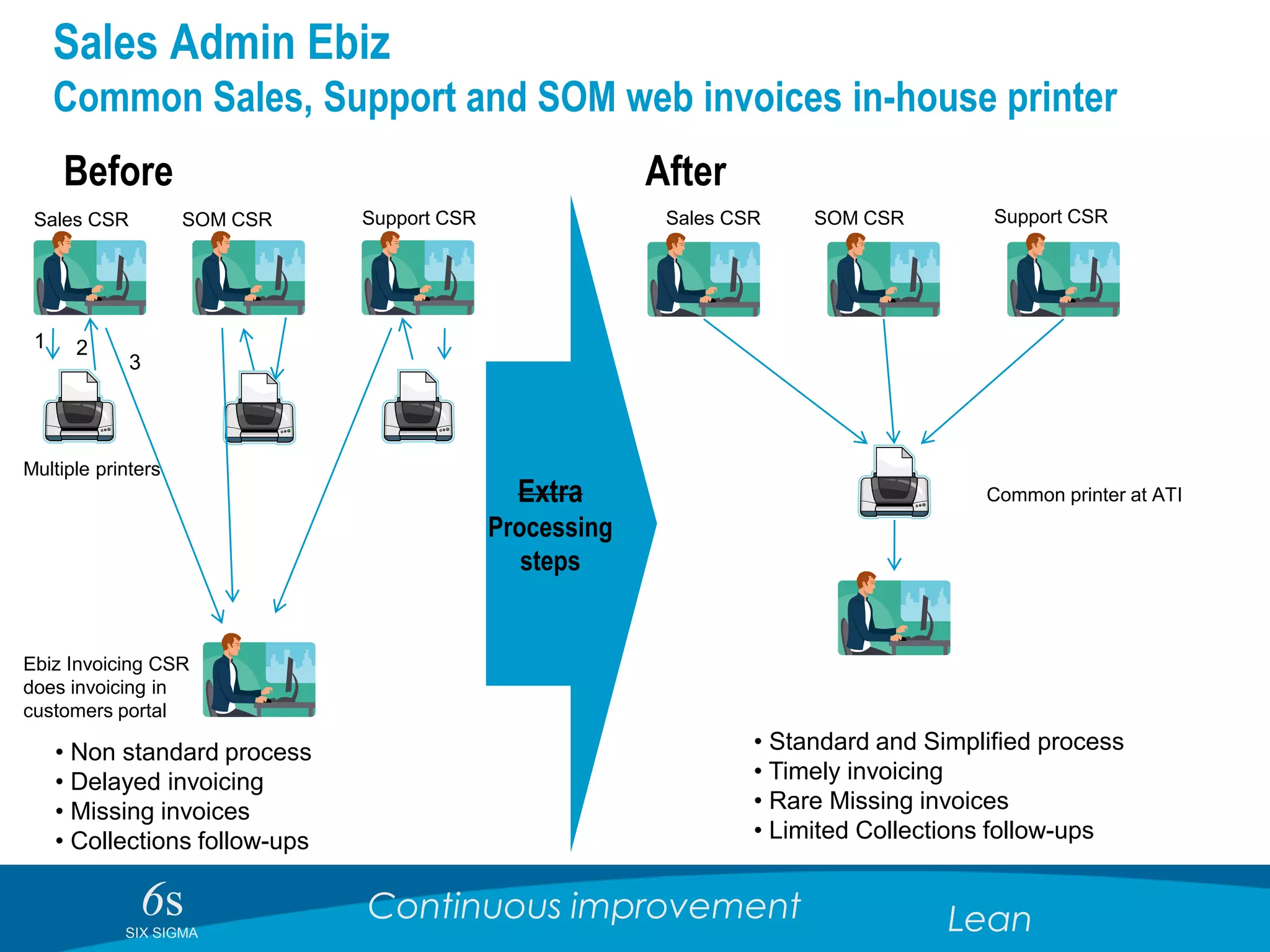

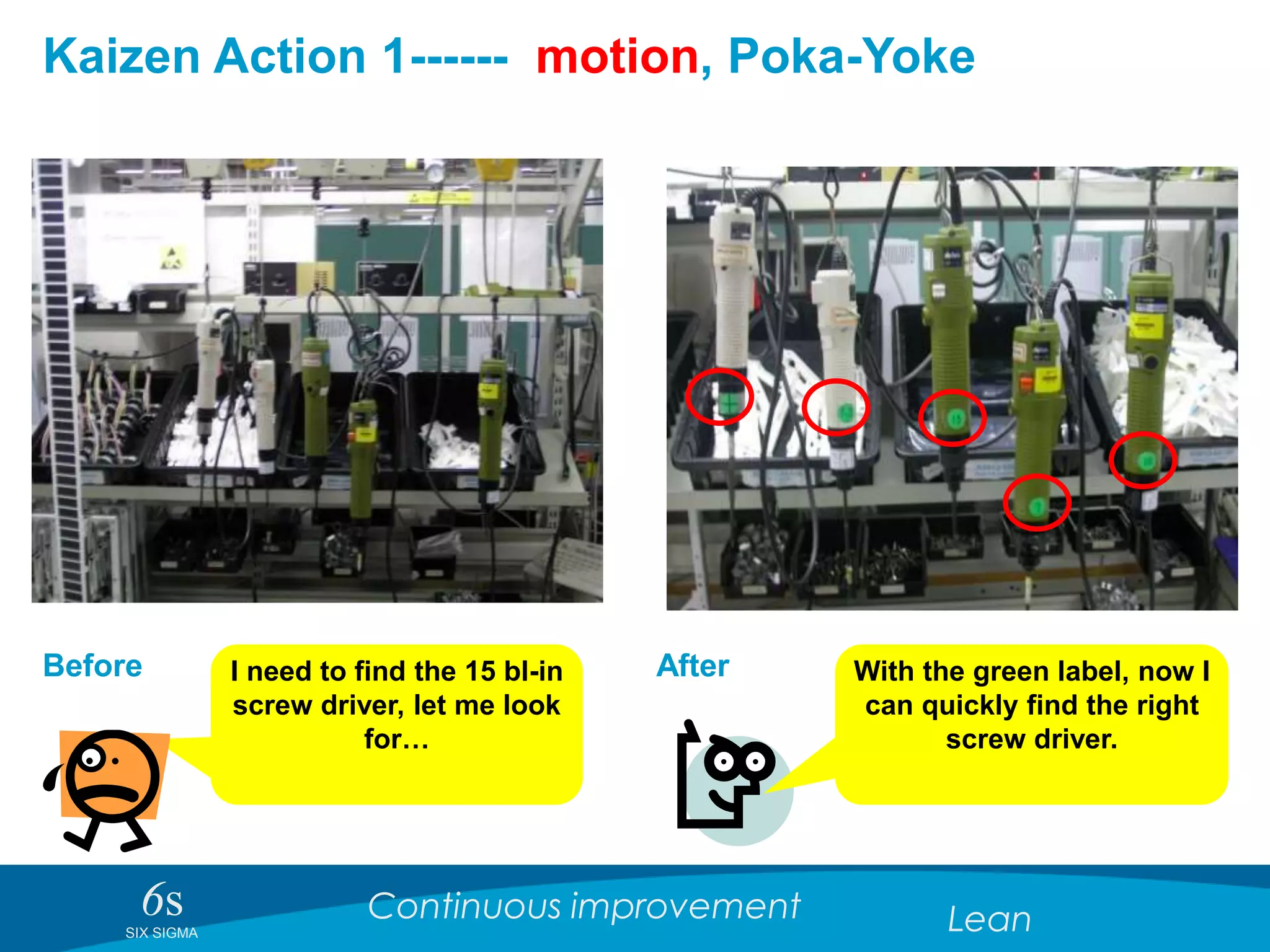

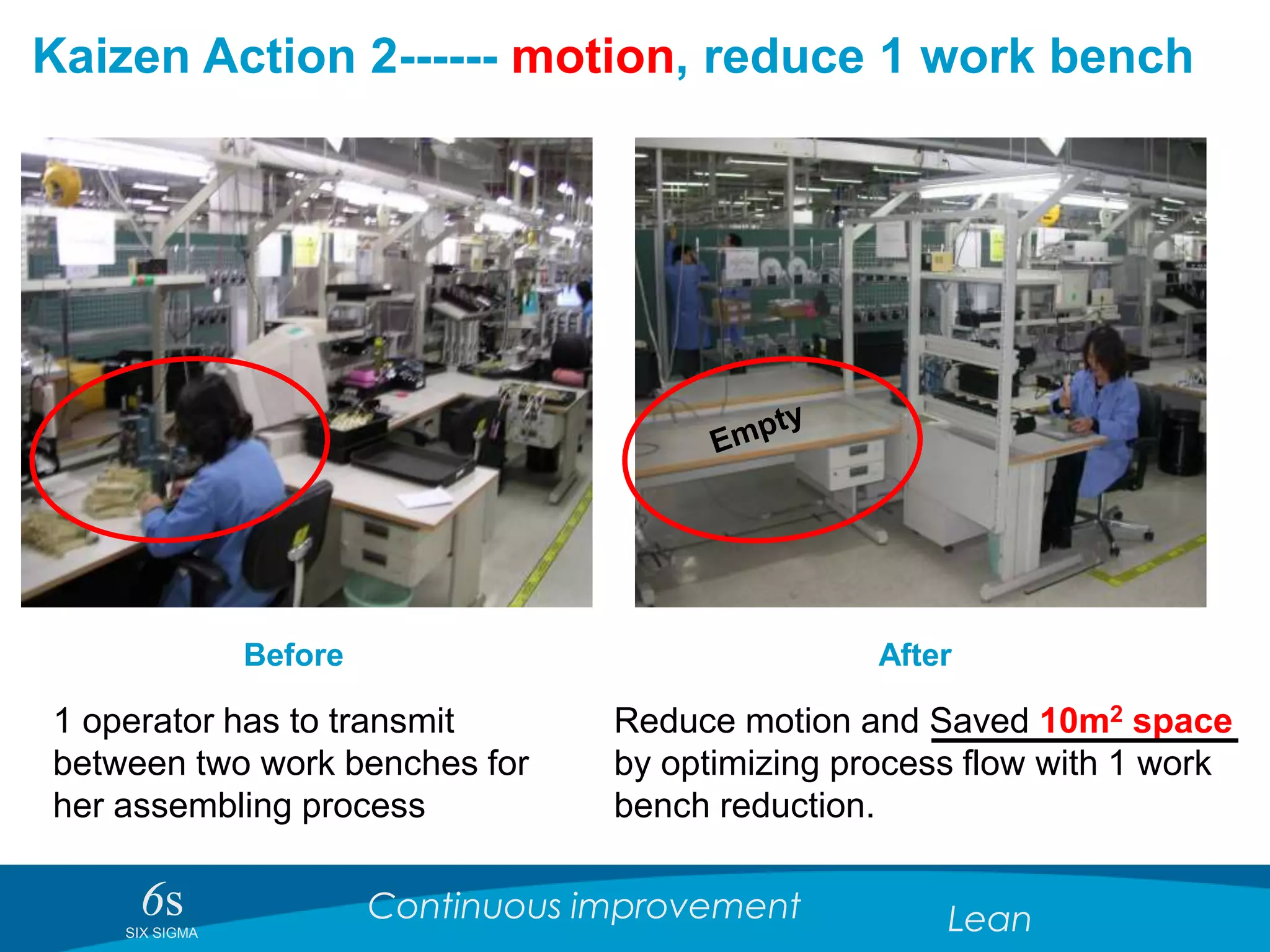

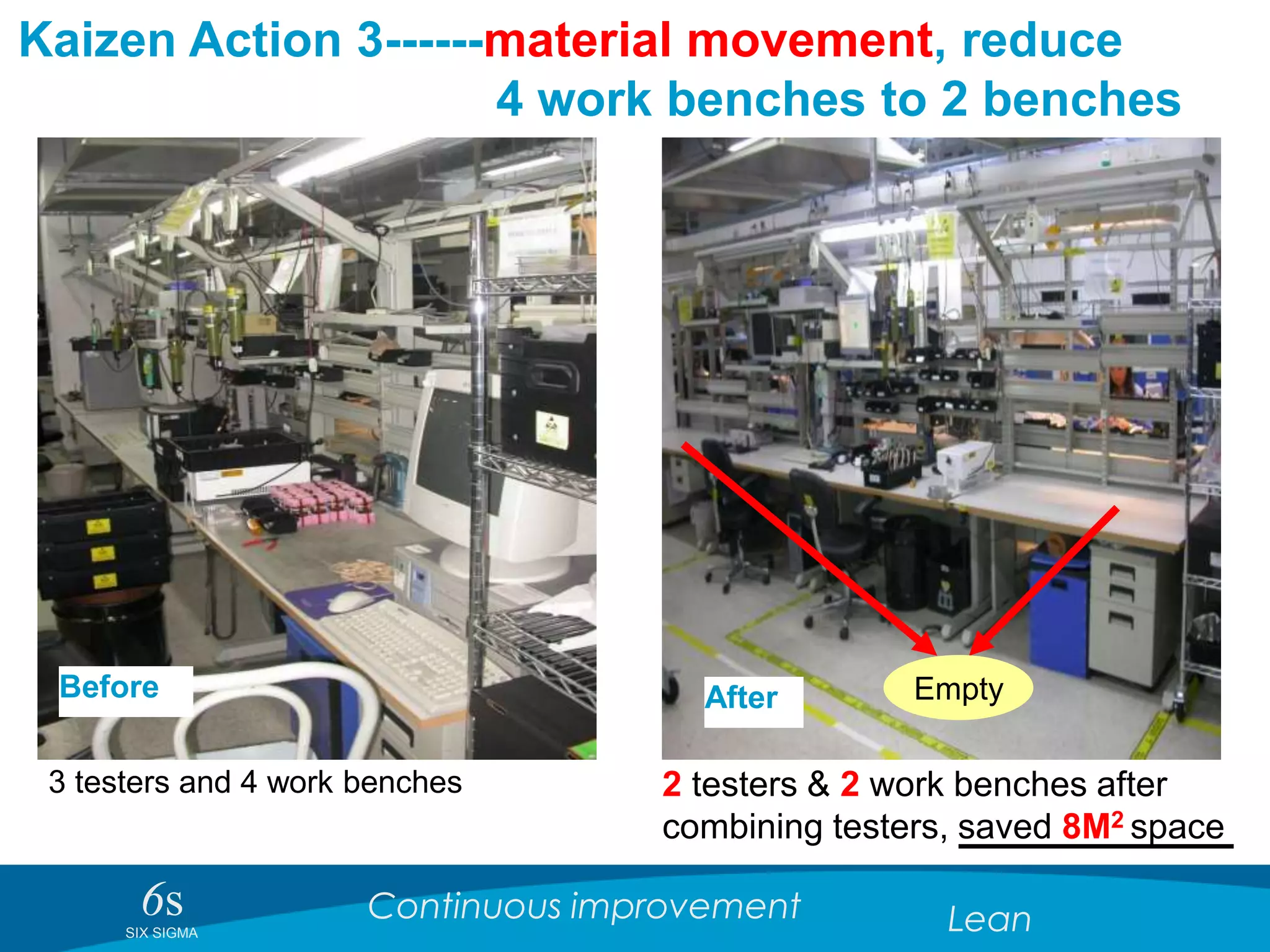

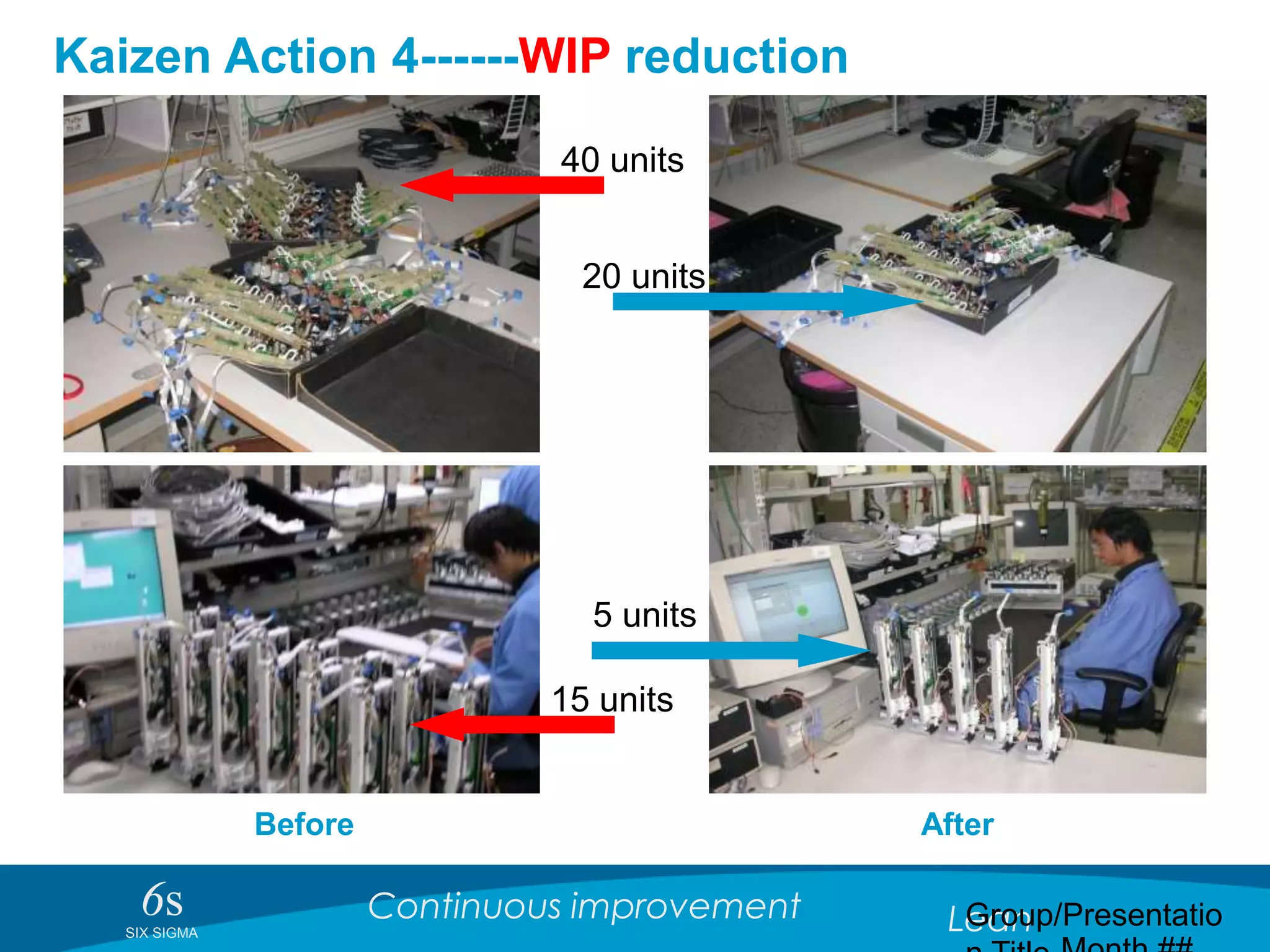

The document outlines the importance of continuous improvement and lean methodologies in logistics, highlighting their roles in increasing efficiency, productivity, and customer satisfaction while reducing costs. It differentiates between lean and continuous improvement (CI) methodologies, emphasizing the use of tools like 5S and value stream mapping to identify and eliminate waste. Real-life examples illustrate the successful implementation of these methodologies in organizational processes.