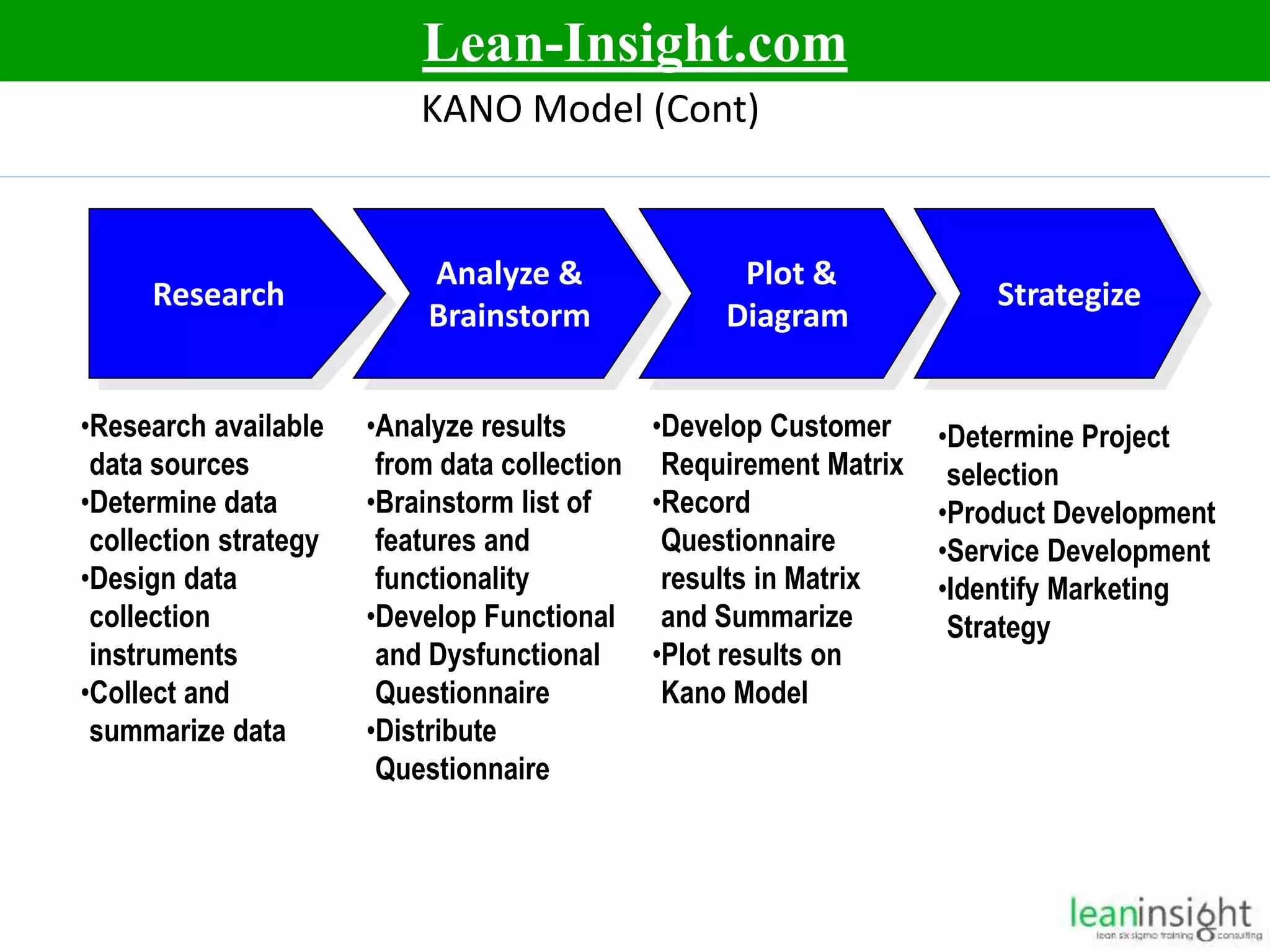

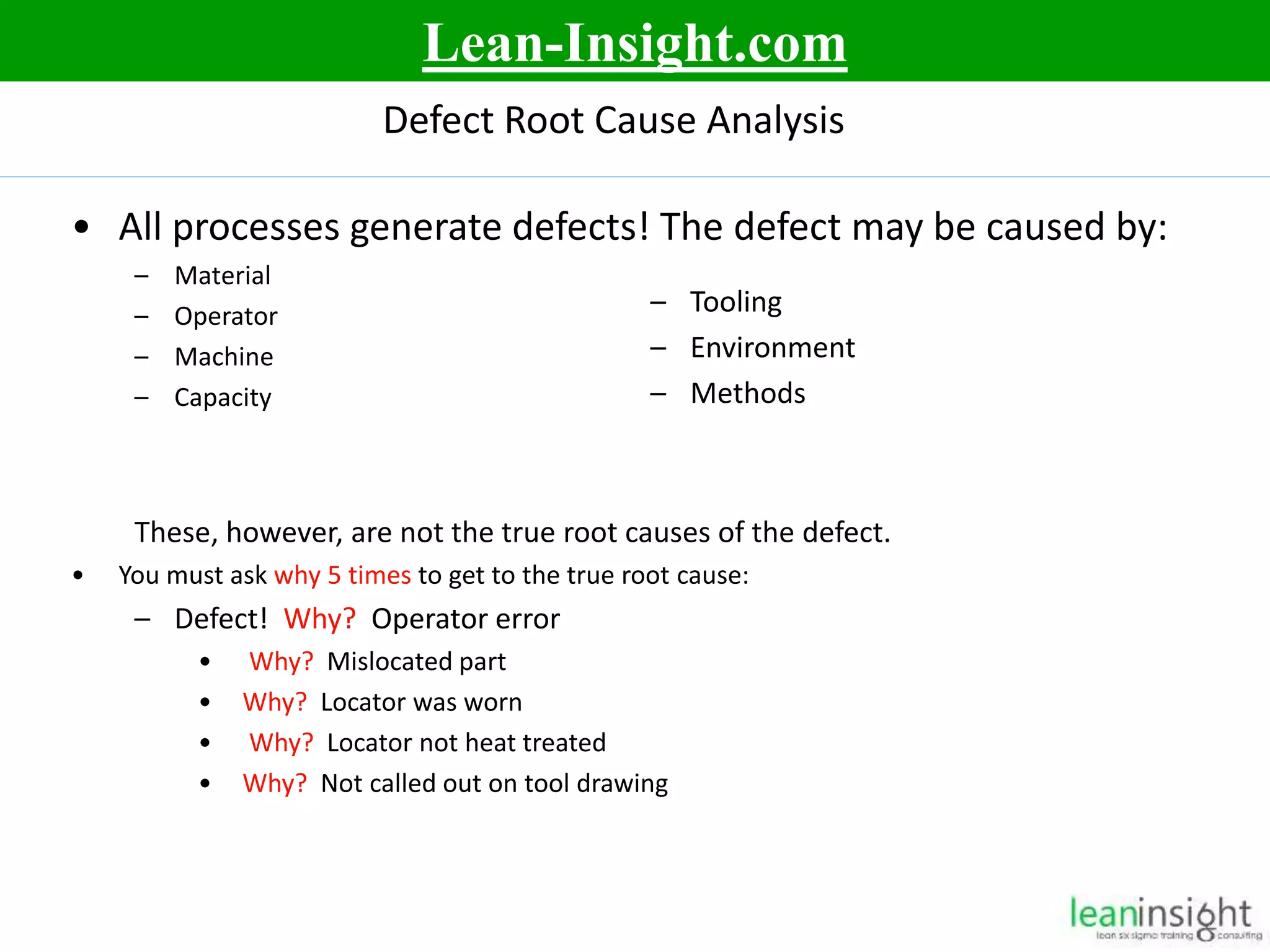

The document outlines Lean Six Sigma training concepts, emphasizing the Kano model and the 8 principles of quality management, which include customer focus, leadership, involvement of people, process and system approaches, continual improvement, factual decision-making, and mutually beneficial supplier relationships. It stresses the importance of understanding customer needs, effective leadership, employee involvement in decision-making, and continuous improvement for business success. The document also highlights data collection and analysis as critical components for determining root causes of defects and strategizing improvements.